The history of lithium batteries

"Lithium-ion battery", is a class of batteries made of lithium metal or lithium alloy as the negative electrode material, using a non-aqueous electrolyte solution. Lithium batteries can be broadly divided into two categories: lithium metal batteries and lithium-ion batteries. Lithium-ion batteries do not contain lithium in the metallic state and are rechargeable.

Lithium metal batteries were first proposed and studied by Gilbert N. Lewis in 1912.

In the 1970s, M. S. WhitTIngham proposed and began researching lithium-ion batteries. M.S. WhitTIngham used titanium sulfide as the cathode material and lithium metal as the negative electrode material to make the first lithium battery.

The positive electrode material of lithium battery is manganese dioxide or thionyl chloride, and the negative electrode is lithium. After the battery assembly is completed, the battery voltage, do not need to charge, and can not be charged, is a single-use battery. For example, the former camera used in the button battery belongs to the lithium battery. This battery can also be recharged, but the cycle performance is not good, in the process of charging and discharging cycle is easy to form lithium crystals, resulting in internal short circuit, so in general this battery is prohibited from charging.

In 1980, J. Goodenough discovered that lithium cobaltate could be used as the cathode material for lithium-ion batteries.

In 1982, R.R. Agarwal and J.R. Selman of the Illinois Institute of Technology discovered that lithium ions have the property of being embedded in graphite, and this process is fast and reversible. At the same time, lithium batteries made of lithium metal are purely a safety hazard, so attempts have been made to use the properties of lithium ions embedded in graphite to make rechargeable batteries.

The first available lithium-ion graphite electrode was successfully piloted by Bell Labs.

In 1983, M. Thackeray, J. Goodenough and others found that manganese spinel is an excellent cathode material with low cost, stability and excellent conductivity and lithium conductivity. It has a high decomposition temperature and much lower oxidation than lithium cobaltate, which can avoid the danger of combustion and explosion even if there is a short circuit and overcharge.

In 1989, A. Manthiram and J. Goodenough found that the cathode using polymeric anion will produce higher voltage.

In 1992, Sony Japan invented the lithium battery with carbon material as the negative electrode and lithium-containing compound as the positive electrode. During the charging and discharging process, no lithium metal exists, only lithium ions, which is the lithium-ion battery. Subsequently, lithium-ion batteries have revolutionized the face of consumer electronics. Such batteries with lithium cobaltate as the cathode material are still the main power source for portable electronic devices.

In 1996, Padhi and Goodenough discovered that phosphates with olivine structure, such as lithium iron phosphate (LiFePO4), are safer than traditional cathode materials, especially high-temperature resistant and far more resistant to overcharging than traditional lithium-ion battery materials. Therefore, it has become the mainstream cathode material for high-current discharge power lithium batteries.

Do You Know What' s a Cylindrical Lithium-Ion Battery?

-Definition

Cylindrical lithium-ion battery, in fact, the cylindrical means that this lithium-ion battery is shaped like a stick-like form. This is a very graphic description. There are many different types of cylindrical lithium-ion batteries, which are divided mainly according to the different cathode materials. For example, if the cathode material is lithium cobaltate, then the battery will be named lithium cobaltate cylindrical battery. Lithium-ion battery cathode materials are lithium cobalt oxide (LiCoO2), lithium manganese (LiMn2O4), lithium nickel cobalt manganate (LiNiMnCoO2 or NMC), lithium aluminum nickel cobalt (LiNiCoAlO2 or NCA), lithium iron phosphate (lithium iron phosphate) and lithium titanate (Li4Ti5O12). It is because of the different cathode materials, so there will be so called lithium cobaltate cylindrical batteries, lithium iron phosphate batteries, lithium carbonate cylindrical batteries.

There are many types of cylindrical lithium batteries, including 14500, 14650, 18500, 18650, 21700, 26650, 32650, these sizes are developed with a certain history and reality. For example, the size of 14500 was the standard size at the time of NiMH and NiCr batteries, which were called AA batteries, and lithium-ion batteries just followed the standard of NiMH and NiCr batteries. Lithium-ion batteries are widely used in energy storage systems, digital products, industrial support, special equipment, medical equipment, instrumentation, handheld devices, security and communications.

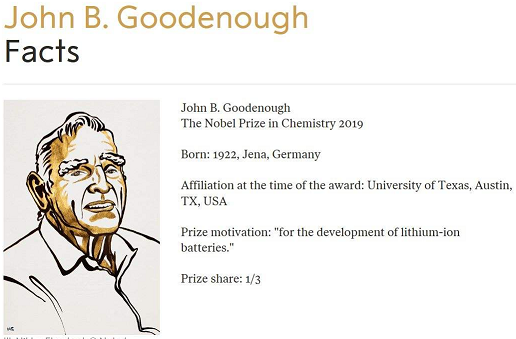

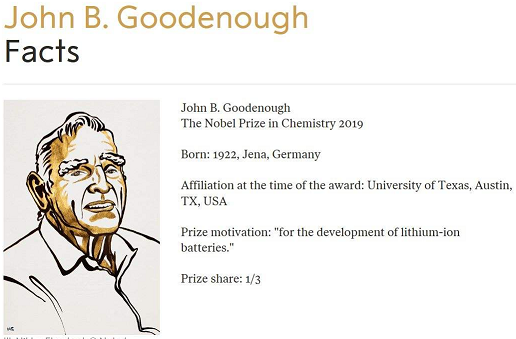

-Construction

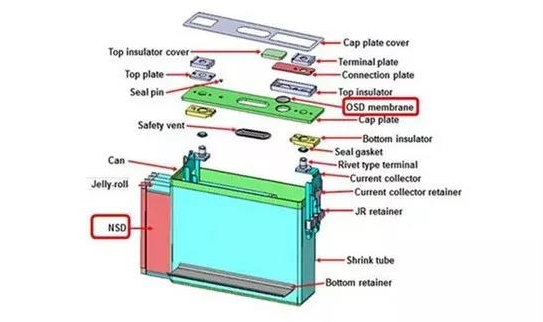

A typical cylindrical battery structure includes: positive electrode, negative electrode, separator, electrolyte, steel case, cap, PTC element, gasket, anti-explosive valve, etc. Generally, cathode material, anode material, electrolyte, and diaphragm are the key to determine the performance of lithium ion, while PTC is the core component to protect lithium-ion batteries.

What are the advantages of cylindrical lithium batteries?

Cylindrical lithium battery is a common form of lithium battery, the earliest cylindrical lithium battery was created and invented by Japan's SONY group of companies in 1992, when the model used was 18650 lithium battery.

Therefore, the development history of 18650 cylindrical lithium battery is very long, the industry market coverage is high, the level of mechanical automation is high, the product quality is relatively stable, and the cost is relatively low.

1.A series of internationally unified standard specifications and models have been formed, and the process is relatively mature and suitable for continuous production in large quantities.

2.The specific surface area of cylindrical body is large, and the heat dissipation effect is good.

3.The cylindrical lithium battery has a very high sealing, and there is no maintenance problem during use.

4.The lithium battery shell has high pressure resistance, and there is no phenomenon such as prismatic and polymering battery expansion during use.

5.Cylindrical lithium-ion batteries are very suitable for series or parallel connection.

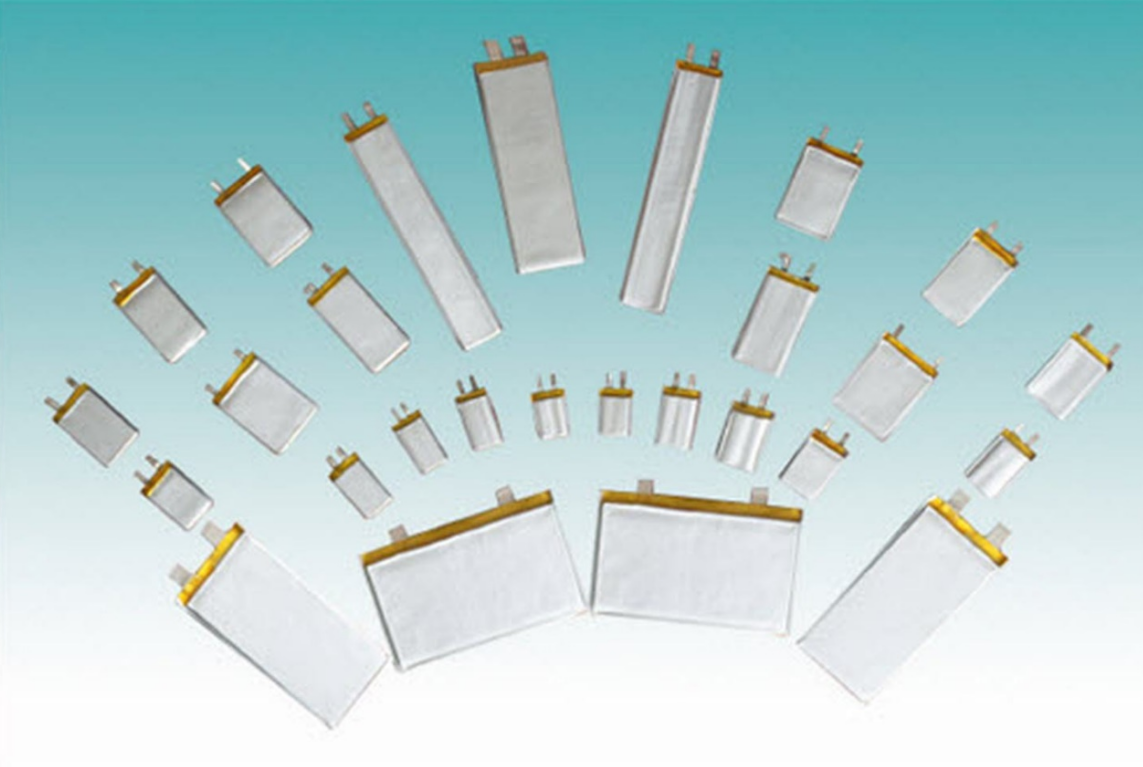

Do You Know What is a Polymer Lithium-ion Battery?

-Definition

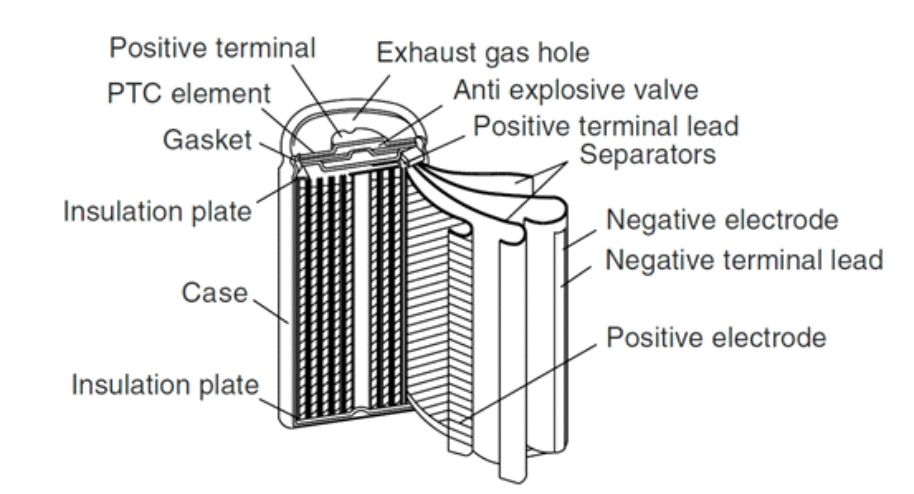

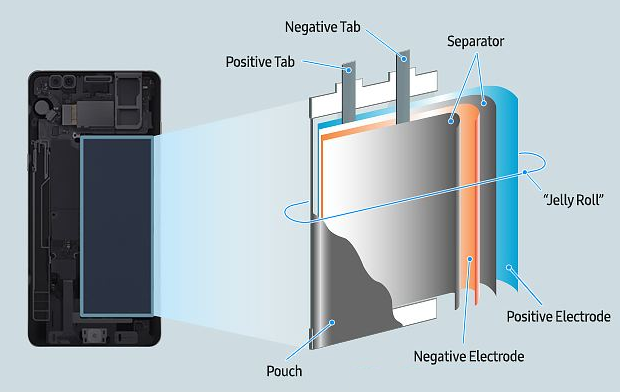

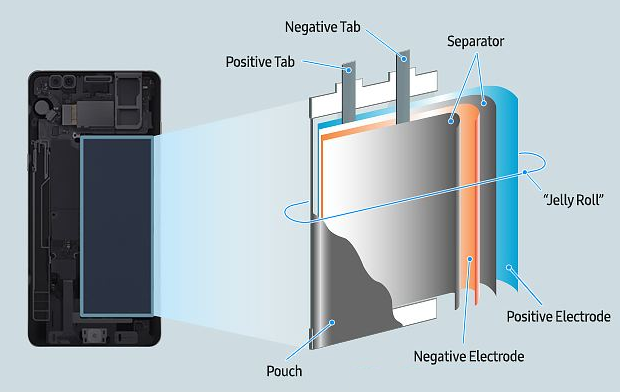

Li-polymer batteries, also a type of lithium-ion battery, work on the same principle as cylindrical lithium-ion batteries. The most obvious difference between the two is that cylindrical lithium-ion batteries are wrapped in a cylindrical steel case, while Li-polymer batteries are wrapped in a paper-like aluminum plastic film. Its form is completely different from the cylindrical lithium-ion battery, which is presented as a thin prismatic.

Polymer batteries use polymer materials in at least one of the three major components: positive electrode, negative electrode or electrolyte. Polymer means high molecular weight, and its corresponding concept is small molecule. Polymer has high strength, high toughness and high flexibility. The polymer materials currently developed for polymer batteries are mainly used for the cathode and electrolyte.

-Construction

In addition to using materials that are somewhat different from cylindrical lithium-ion batteries, we can see from the figure below that the most important feature of lithium polymer batteries is that they use aluminum-plastic film as the shell, and then during the manufacturing process, the aluminum-plastic film is fused together by heating and other methods to form a solid hermetic body.

Note that, compared to cylindrical lithium-ion batteries, lithium polymer batteries are missing the PTC, which will lead to the safety of the battery to produce hidden risks? Of course not. In fact, the safety of Li-Polymer batteries is far better than that of cylindrical Li-Ion batteries, as you can find out in other articles by SES Power.

What are the advantages of Polymer lithium batteries?

Lithium polymer batteries have a prismatic shape and are ultra-thin, allowing them to be made in any shape and capacity to meet the needs of various products. With the development of technology, the capacity of lithium polymer battery can reach 80ah or even higher.

1.Polymer batteries can be thin, any area and any shape. For example, a single cell capacity of 500mAh, the thickness can be as thin as 0.5mm.

2.The battery can be bent and deformed: polymer batteries can be bent up to about 90 degrees.

3.The capacity will be 30% higher than the same size of cylindrical lithium-ion battery.

4.Because of the large extension of the positive and negative pole ear, lithium polymer batteries can withstand greater current, such as aviation toys with high-rate lithium batteries are almost all lithium polymer batteries.

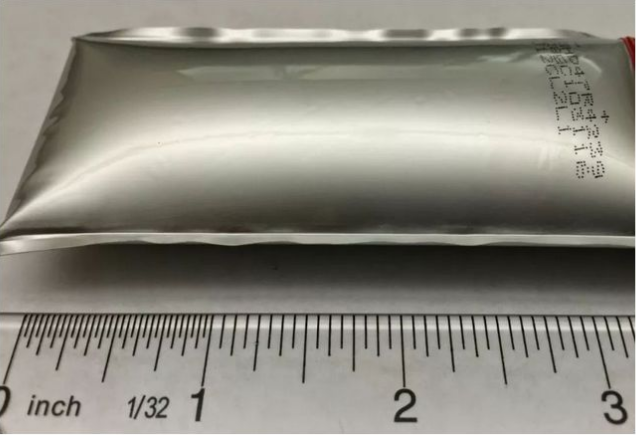

5.The use of aluminum-plastic film as a shell, when the internal use of organic electrolyte, even if the liquid is very hot, it does not explode, because the aluminum-plastic film polymer batteries produce deformation or natural rupture.

Do You Know What is a Prismatic Lithium-ion Battery?

-Definition

The prismatic lithium-ion battery, again, works on the same principle as other types of lithium-ion batteries. The difference is that the prismatic lithium-ion battery is wrapped in a prismatic aluminum case. Although both are prismatic in shape, the lithium polymer battery presents a thin and long form, like a very thin book, while the prismatic lithium-ion battery presents a very heavy state, like a Britannica dictionary.

The performance characteristic of prismatic lithium-ion battery is that it can achieve very high capacity of single cell, now there are 100ah single cell and 200ah single cell commonly available in the market. In some famous big factories, such as CATL, EVA, etc., they are producing more than 300ah prismatic lithium-ion batteries.

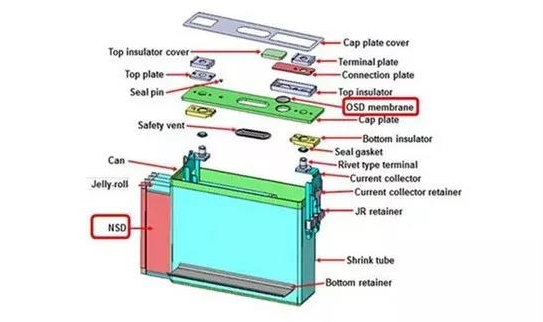

-Construction

A typical prismatic lithium battery, the main component parts include: top cover, shell, positive plate, negative plate, diaphragm consisting of laminated or wound, insulating parts, safety components, etc. Among them, the two in the red circle are the safety structure, NSD pinprick safety device; OSD overcharge protection device.

Needle puncture safety device (NSD). This is a metal layer, such as a thin sheet of copper, added to the outermost part of the roll core. When a pinprick occurs, the local high current generated at the pinprick location is quickly reduced per unit area by the large area of copper sheet, which prevents local overheating at the pinprick location and reduces the occurrence of thermal runaway of the battery.

Overcharge Safety Device (OSD), currently this safety design can be seen in many batteries. Generally, a metal sheet, with the use of fuse, fuse can be designed to the positive collector fluid, overcharge the internal pressure generated by the battery makes the OSD trigger an internal short circuit, resulting in an instantaneous high current, so that the fuse fused, thereby cutting off the internal current circuit of the battery.

Of course, how lithium batteries are designed will have safety issues, if you want to know how international standards test lithium batteries, lithium battery performance standards, you can find the answer within SES Power's webpage.

The shell is generally steel or aluminum, with the market driven by the pursuit of energy density and the progress of the production process, aluminum shell gradually become mainstream.

What are the advantages of Prismatic lithium batteries?

Prismatic lithium battery the biggest advantage of its process and structure determines that it can achieve a very high capacity, it is said that the largest prismatic lithium-ion battery can do 500ah, my goodness, what a concept!

1. Prismatic lithium-ion battery package reliability is high;

2. High energy efficiency of the system; relatively light weight, high energy density;

3. The structure is relatively simple, is currently an important option to improve energy density by increasing the capacity of a single cell;

4. The large capacity of the single unit, the system composition is relatively simple, making it possible to monitor the single unit one by one. Another benefit of the simple system is the relatively good stability.

Cylindrical lithium battery, polymer lithium battery, prismatic lithium battery, how to choose?

According to different packaging forms, batteries are classified into cylindrical lithium-ion batteries, lithium polymer batteries, and prismatic lithium-ion batteries. Different structures also mean they have different characteristics. Today SES Power takes a look at the disadvantages of each of these three structures of batteries.

-Cylindrical lithium-ion batteries

Cylindrical batteries have been developed for the longest time, and the technology is also the most mature, with a higher degree of standardization. And because cylindrical batteries have a larger space between the individual cells in the package, so these batteries have a great advantage in heat dissipation, many models equipped with cylindrical batteries have adopted lower-cost air-cooling technology.

Maturity naturally makes the cost low enough, but also makes the supply chain is very good, which is the most core advantage of cylindrical lithium-ion batteries. This is also the cylindrical lithium-ion battery can be used in any application.

But its structure brings safety problems, has always troubled the R & D staff, which is almost insurmountable problem, about lithium cobalt acid, ternary lithium battery safety accidents are often seen in facebook, tiktok, Youtube, etc., even if the use of high safety performance of lithium iron phosphate materials, there is still a certain probability of security problems, although the probability is very low.

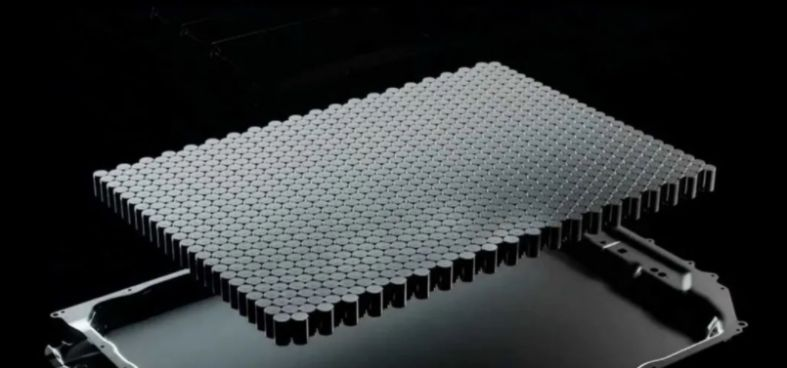

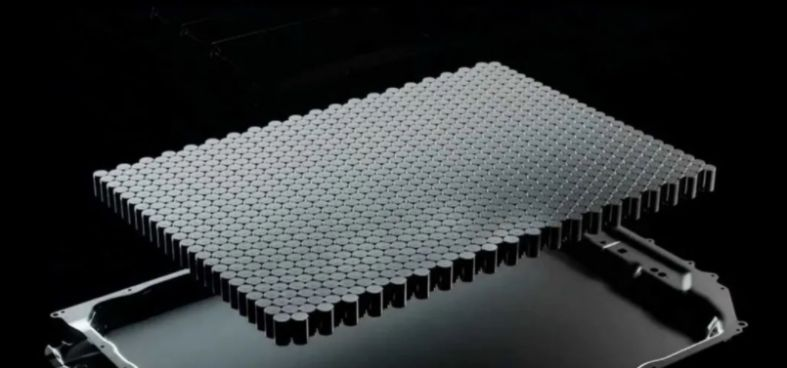

At the same time, because the capacity of a single cell is too low, making the combination of high voltage, high capacity, the battery pack cell number is amazing, this can be referred to the Tesla models actually used how many cylindrical lithium-ion cells is very clear. Thousands of cylindrical batteries put together, which for the vehicle's battery management system put forward extremely high requirements. In addition, because cylindrical batteries need to use steel cases when combined into battery packs, their weight is relatively high, and theoretically the energy density of cylindrical batteries is lower than the other two types of batteries.

At present, many models on the market use this type of battery, more representative is Tesla's model 3, using almost qty 5,000 pcs of 21700 (where 21 means the diameter of the cylindrical battery is 21mm, 70 means the length of the battery is 70mm, 0 means its type is cylindrical battery) cylindrical battery cells.

-Lithium polymer batteries

Lithium polymer batteries use a special manufacturing method and are thinner in size compared to the other two types of batteries, so its energy density is theoretically the highest among the three types of batteries. And because of its smaller size, the lithium polymer battery is better than the other two types of batteries in terms of its overall product appearance and flexibility of internal layout.

The characteristics of lithium polymer batteries make them the first choice for consumer products because they are powerful, light enough, and can be tossed around in different shapes, no longer tying the hands of art-filled engineers.

Of course, now lithium polymer batteries are also moving in the direction of high capacity in an attempt to capture a significant share of the new energy industry, such as electric vehicles and energy storage systems. However, because of the stacked design inside the lithium polymer battery, it is necessary to add a layer of sheet in between each two cells, which will be filled with liquid and heated or cooled to ensure that the battery is at the optimal operating temperature, which also means that the lithium polymer battery requires a more complex battery control system.

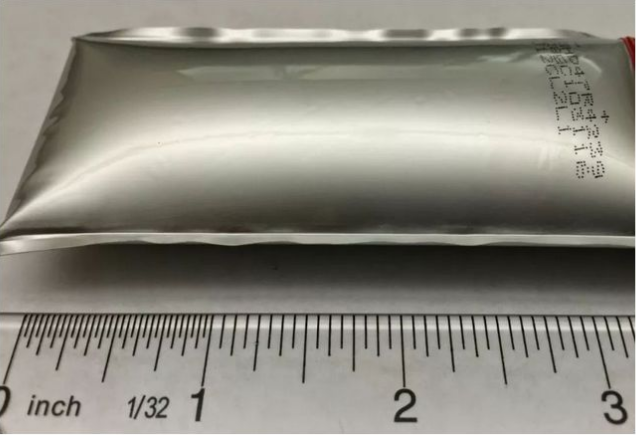

At the same time, because the aluminum-plastic film is stretchable, and the prismatic structure makes the form can be very variable, which is an advantage, but also brings another disadvantage - expansion. This has always been a headache for engineers. Because when the lithium-ion battery is charged and discharged, the internal pressure will be generated, which will lead to the expansion of the battery, because the same surface area, the round body is the largest capacity of the form. At the same time, this disadvantage brings an advantage - not easy to explode and catch fire.

Another disadvantage is that lithium polymer batteries use polymer materials, which are costly, while the production process is complex, making the final product more expensive than the other two forms of batteries.

-Prismatic lithium-ion batteries

The popularity of prismatic lithium-ion batteries is increasing, because the structure of prismatic lithium-ion batteries is simpler, the production process is not complicated, and prismatic lithium-ion batteries do not use higher strength stainless steel as the shell, so the energy density of prismatic lithium-ion batteries is theoretically higher than the energy density of cylindrical batteries.

Prismatic lithium-ion batteries currently seem more suitable for new energy, such as electric vehicles, large energy storage systems, UPS, data centers and other scenarios that require the use of large-capacity batteries. The current classification of prismatic lithium-ion batteries are mainly lithium iron phosphate, ternary lithium batteries.

As the prismatic lithium-ion batteries are generally customized design, resulting in the production process of prismatic lithium-ion batteries is difficult to unify, its standardization is low. In addition, the factory construction of prismatic lithium-ion batteries is very expensive, because the process of prismatic lithium-ion batteries requires very high requirements for the production of the front-end process of the cell, and the environmental requirements of the factory are also very high.

The biggest advantage of prismatic lithium-ion batteries is the amazing capacity, Tesla's models assume the use of prismatic lithium-ion batteries, in fact, more than a hundred prismatic lithium batteries is enough, compared to the use of nearly 5,000 217, is not felt not a class?

Of course, theoretically the price of prismatic lithium-ion battery is able to be equal to cylindrical batteries, or even lower, because of the savings in labor, but because of higher factory construction costs, now the prismatic lithium-ion battery has not presented enough cost advantage.

-Summary

In the current market, cylindrical, prismatic, polymer three kinds of batteries are a large number of products on board, they are not absolutely good or bad, can only say that each has its own advantages. In terms of cell energy density, theoretically, lithium polymer batteries are the highest, prismatic lithium-ion batteries are the second highest, and cylindrical batteries are the smallest. In different scenarios, different applications, different products to be able to choose the most appropriate lithium-ion battery, is the need for sufficient knowledge and experience, this, SES Power years of experience can help you, more battery or new energy system knowledge, you can find the answer on our website, you can also send us an email or facebook, collage contact us. Customized service will give you the most correct and suitable answer.