Dr. Wang, head of the CATL fast charging project, explained that the focus

of fast charging is on the negative electrode, and for the choice of positive

electrode, whether it is ternary or lithium iron phosphate, it will not affect

the performance of fast charging and its reliability. .

Improving the energy density and fast charging performance of power

batteries is considered a feasible way to relieve consumers’ anxiety about

mileage.

Under the pressure of linking the amount of subsidy to energy density, a

large number of domestic power battery companies have achieved substantial

increases in energy density by improving the material system and lightweighting

of PACK. The system energy density of 140wh/kg has become a norm. . However, no

major breakthrough has been made in the fast charging performance of power

batteries.

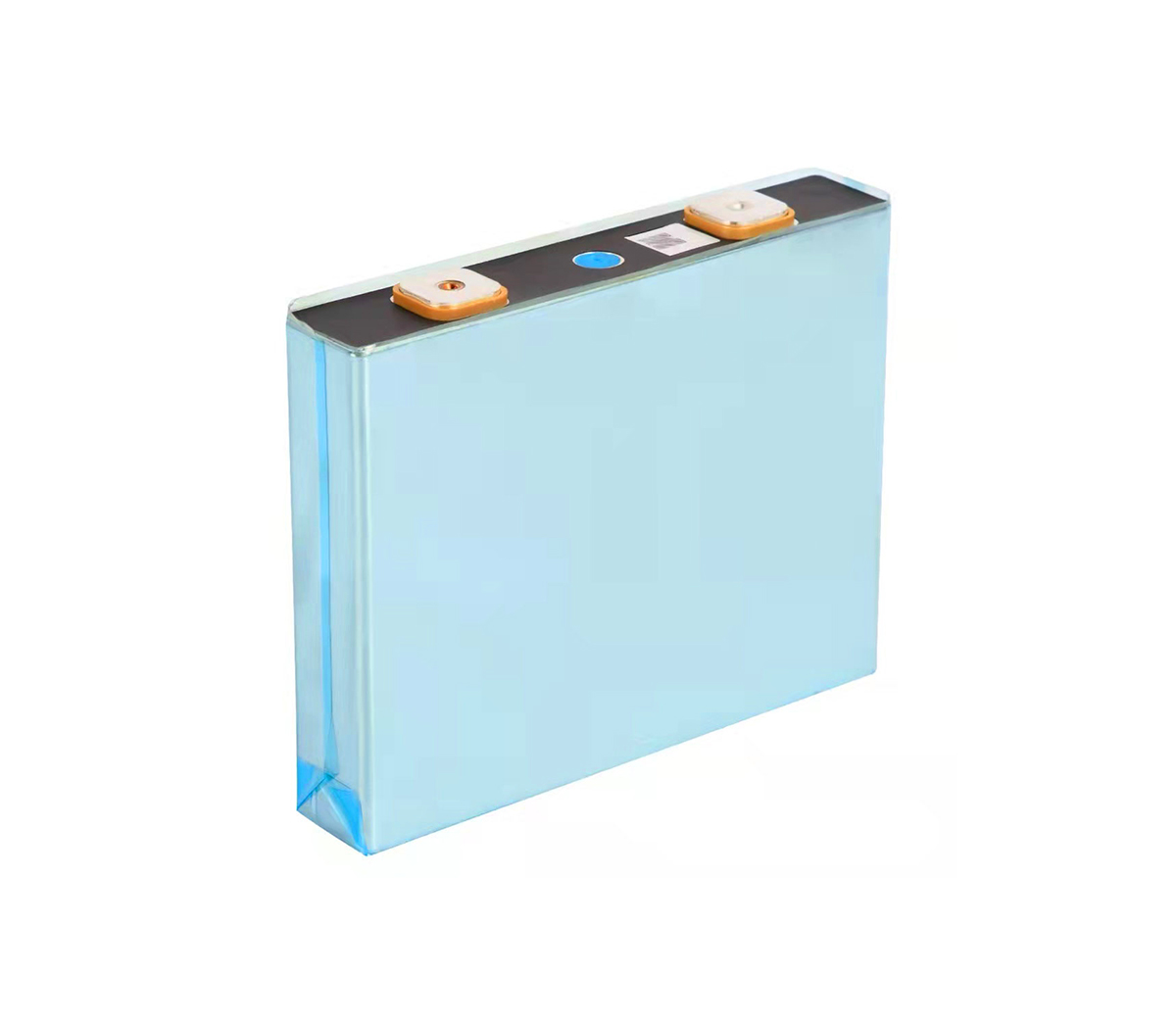

A few days ago, a special seminar on high-power charging of electric

vehicles was successfully held in Ningde. During the meeting, CATL showed the

participants the charging process of the EnerSpeedy Super Lithium Lithium

battery using the "Super Lithium Iron + High Energy Density Fast Charging

Graphite" system. The product is a 60Ah super lithium iron battery that can be

charged at 5C. The demonstration process took 7 minutes and 12 seconds to

complete 20% to 80% charging, and 20% to 100% charging took only 13 minutes and

8 seconds.

It is understood that the system energy density of CATL super lithium iron

battery 5C fast energy products is above 70Wh/kg, and 3C high energy products

are above 115Wh/kg, and the cycle life can reach 10,000 times. At the same time,

CATL has also developed a ternary system of fast charging batteries, which can

charge SOC from 5% to 85% within 15 minutes, with an energy density of 190Wh/kg,

and a cycle life of more than 2500 times. The next step is to ensure 4C fast

charging. The density can continue to increase to 210Wh/kg.

Dr. Wang, head of the CATL fast charging project, explained that the focus

of fast charging is on the negative electrode, and for the choice of positive

electrode, whether it is ternary or lithium iron phosphate, it will not affect

the performance of fast charging and its reliability. .

Therefore, CATL adopts the "fast ion ring" technology to modify, the

modified graphite takes into account the characteristics of super fast charging

and high energy density, and no by-products appear in the negative electrode

during fast charging, so the insertion speed of lithium ions in the graphite

layer is greatly improved. So as to achieve excellent rate performance, high

energy density and long cycle life.

Judging from the results achieved by CATL, both lithium iron phosphate

batteries and ternary batteries can achieve fast charging but affect product

performance. This will undoubtedly greatly improve the application of

lithium-ion batteries in electric vehicles, and also provide other battery

companies with Reference and reference. Among the new energy vehicles currently

entering the recommended catalog, the fast charging rate of fast charging

vehicles is basically below 5C, indicating that the fast charging performance of

domestic power batteries needs to be improved. Once a breakthrough can be made,

I believe that China’s new energy vehicle market There will be a real

outbreak.

Let’s take a look at the new technologies and major events in the lithium

battery industry this week.

1. Fujitsu uses artificial intelligence technology to develop lithium

battery technology

Foreign media reported that Fujitsu Co., Ltd. and the Japanese Institute of

Physics and Chemistry announced the latest lithium battery research and

development technology. Both will apply first-principles calculations (quantum

mechanics) and artificial intelligence AI technology to make synthetic

evaluations for the development of new solid electrolyte materials for

lithium-ion batteries. They can also try more materials when the information and

data are incomplete. Combine and be verified in practice. At the same time, with

the support of artificial intelligence technology, the development speed of

lithium battery materials will be greatly increased.

In the development of traditional lithium battery materials, it is

necessary to rely on the long-term accumulated experience and keen intuition of

researchers. When trying to synthesize new materials, the dependence on data is

also high. The first-principles calculations will be based on the predictable

characteristics of quantum mechanics (wave function characteristics), and the

best combination mode of new materials can be perceived before the experiment,

thereby greatly reducing the number of experimental failures. But at the same

time, the load of first-principles calculations is huge, and various

compositions of materials require multiple calculations, which will consume a

long time for research and development.

Therefore, the research team introduced artificial intelligence AI

technology to make it possible to control the number of first-principles

calculations, and more directionally predict the three lithium-containing

oxyacid salt synthetic compounds in the solid electrolyte of lithium-ion

batteries. The results confirm that this method can predict the best material

combination with high lithium ion conductivity in a shorter time. At the same

time, a higher lithium ion conductivity with higher efficiency can be found in

the prediction process.

Comment: Combining quantum mechanics proficient in big data calculations

with AI technology proficient in analysis and calculation to develop lithium

battery technology, compared with artificial brain computing, can indeed greatly

improve the trial and error rate and success rate of research and development,

and all research and development data can be combined The integration

facilitates analysis and comparison, and improves data support for the research

and development of lithium batteries. Once this technology is maturely applied,

the development of new lithium battery technology may be accelerated, so as to

develop a new generation of lithium batteries with higher energy density, longer

life, and safer.

2, graphene oxide accelerates the commercialization of organic lithium

batteries

The lithium metal of lithium battery is prone to generate dendrites

after overcharging or multiple cycles of use, which can then pierce the

isolation layer and cause spontaneous explosion.

Therefore, the University of Illinois at Chicago (UIC) and Texas A&M

University (TAMU) formed a team, hoping to speed up the finding of a solution,

and hope to use supercomputers to understand the chemical and physical

principles of dendrite formation. TAMU professor of chemical engineering Perla

Balbuena said that the team's goal is to develop coatings that can protect

lithium metal and use coatings to slow down lithium deposition.

The team developed a graphene oxide nanolayer sheet that can be sprayed on

the glass fiber separation layer of the battery. These materials allow lithium

ions to flow smoothly, while also slowing down and controlling the speed at

which ions and electrons combine to become neutral atoms. . The coating makes

atomic deposition not uneven like needles, but forms a flat surface at the

bottom.

Researchers use computer models and simulations, combined with physical

experiments and microscope imaging. The results show that lithium ions will form

a thin film on the graphene oxide layer, and then deposit under the graphene

oxide layer through the material gap. The material gap acts like the track of a

nostalgic pinball table, which can slow down the deposition speed and guide

direction.

Graphene oxide can also increase the cycle life of the battery. Compared

with the 120 cycle life of other batteries, the battery can reach 160 stable

cycles.

The graphene oxide can be achieved by cheap and affordable spraying, but

because the coating is very thin, it is a challenge to determine the location.

Balbuena said that in the experiment, it is impossible to determine the coating

on the micro level. The coating is very thin, so it is not Too much need to

pinpoint its location.

Comment: The omnipotent graphene is here again. According to the team’s

research, adding graphene oxide to lithium batteries is not only expected to

solve the lithium dendritic problem, but also to increase the cycle life and

safety of the battery. . But like all the graphene battery news before, the

actual effect of this technology is still in the research stage.