Safety Performance Test Items of Lithium Battery Cells

Lithium batteries have been widely used in all aspects of people's lives, but lithium batteries are hazardous, even if the main safety performance of lithium iron phosphate batteries, as hazardous. In response to these situations, relevant international organizations have developed a series of standards to ensure that people use the power of lithium batteries is safe enough.

For lithium battery cells, the global consensus is to use the UL1642 standard, UL is the English Underwriter Laboratories Inc. It is an independent, non-profit, professional organization that conducts tests for public safety. It uses scientific testing methods to study and determine whether various materials, devices, products, equipment, buildings, etc. are hazardous to life and property and the extent of the hazards; to determine, prepare, and issue appropriate standards and information to help reduce and prevent damage to life and property, and to conduct factual research operations. In short, it is mainly engaged in product safety certification and management safety certification business, and its ultimate goal is to contribute to the market for goods with considerable safety standards and to ensure the safety of human health and property. In terms of product safety certification as an effective means of eliminating technical barriers to international trade, UL also plays an active role in promoting the development of international trade.

Lithium battery UL certification is usually divided into two kinds.

UL1642: for lithium ion cell

UL2054: for lithium ion battery pack

UL1642 (cell)

Electrical Test: Over charge, over discharge, external short circuit, forced discharge, etc.

Mechanical Test: Extrusion, puncture, impact, vibration, drop, etc.

Temperature Performance Test: High and low temperature cycle, combustion, microwave heating, etc.

-Environmental Simulation

High and low pressure simulation, salt spray test, etc.

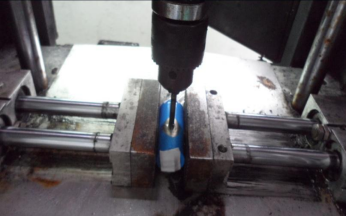

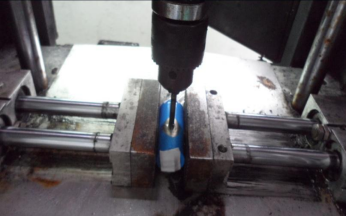

-Puncture Test

This is one of the most controversial test items. The process is to place a fully charged battery on a flat surface and puncture the battery in the radial direction with a 3mm diameter steel needle. The test battery does not catch fire and does not explode.

-Impact Test

The full-capacity battery is placed on a flat surface, applied with a squeezing pressure of 13±1KN, and the battery is squeezed with a 32mm diameter steel rod flat surface, and the battery does not catch fire and does not explode.

-Extrusion Test

The full-capacity battery is placed on a flat surface, and use oil cylinder to apply 13± 0.78KN extrusion pressure. Then the battery has plane extrusion by the steel bar with 32mm diameter. If the extrusion pressure reaches the maximum value, and the battery cell does not catch fire or explode, the battery cell passes the test.

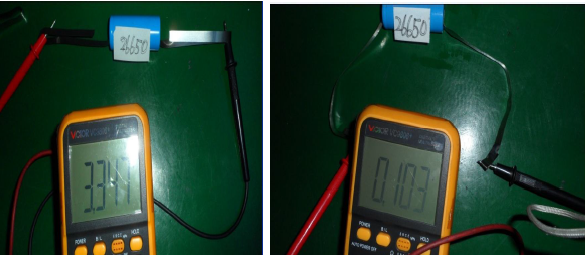

-Forced Discharge

The cylindrical lithium cell is discharged to the discharge cut-off voltage at a standard discharge current and then the cell is placed in the explosion-proof box. The battery anode is connected to the DC cathode, and the battery cathode is connected to the DC anode.

-Overcharge Test

Fully charge the battery with 1C and carry out an overcharge test in accordance with 3C overcharge 10V. Keep 10V high-voltage charging for a standard period of time, during which the battery does not catch fire and explode.

-Short Circuit Test

After the battery is fully charged with a resistance of not more than 50mΩ wire to short circuit the positive and negative terminals of the battery, test the battery surface temperature change, the maximum temperature of the battery surface is 140 ℃, the battery does not catch fire and does not explode.

-Thermal Shock Test

Put the fully charged cylindrical Li-ion battery into the high-temperature cabinet and heat it up to 130℃±2℃ at a rate of (5℃±2℃)/min and keep the cell for 30min. If the cell does not catch fire or explode, test passed.

-Combustion

Experiments to determine if cylindrical lithium batteries explode or cause other destructive damage when burned.

UL2054 (pack)

Lithium-ion battery packs are generally tested with UL2054 standard.

UL2054 standard is the standard related to battery packs, the scope is for having two or more batteries in series or parallel combined together in the use of battery packs.

UL2054 has a wide range of tests, mainly including:

-Short-Circuit Test

Test Method

➢ An 80m ohm resistor is connected between the positive and negative terminals of the battery pack, and the test environment needs to be conducted at 20°C and 55°C.

➢ The power board components in the battery pack need to be failed in sequence (except for components certified to UL1434 or UL60730-1A, as the standard determines that components certified to these two standards meet safety specifications).

Judgment

➢ The sample must not catch fire during the test and there must be no chemical leakage due to sample rupture during the test sample test.

➢ The board and covered gauze during the test must not be ignited or carbonized.

➢ The maximum internal temperature of the cell during the test must not exceed 150°C.

-Abnormal Charging Test

Test Method.

➢ The battery pack needs to be charged 3 times continuously at an ambient temperature of 20°C, with the following formula for each charge time.

Time per charge = (2.5 * rated capacity of the battery pack) / (3 * rated charge current)

Note: Each charging time is at least 7 hours; if the overcharge protection operates during charging, the overcharge protection device needs to be disabled.

Judgment

➢ The sample must not catch fire during the test, and there must be no chemical leakage caused by sample rupture during the test sample test.

-Abusive Overcharge Test

Test Method

➢ The battery pack needs to be overvoltage charged at 20°C ambient temperature at 10 times the voltage of C5 until thermally stable condition.

➢ If the battery pack is PTC type temperature protected, the PTC needs to be allowed to operate 10 times.

Note: C5 is the voltage of the battery after 5 hours of continuous discharge in a fully charged state (according to the manufacturer's nominal); In addition, the test process requires a failure process protection device (in addition to components that meet UL1434 or UL60730-1A certification, because the standard determines that the components certified by these two standards meet the safety specifications).

Judgment

➢ The sample must not catch fire during the test, and there must be no chemical leakage caused by sample rupture during the test sample test.

-Forced-Discharge Test

Test Method

➢ An 80m ohm resistor is connected between the positive and negative terminals of the battery pack, and the test environment needs to be at 20°C.

➢ The power board components in the battery pack need to fail in sequence (except for those components that meet UL1434 or UL60730-1A certification, as the standard determines that components certified to these two standards meet safety specifications).

Note: The battery pack for this test needs to be connected to a single battery in series with a completely discharged battery pack (the number of single cells is the number of battery pack cells minus one, and the single cell needs to be fully charged); the battery pack for this test needs to be connected to a single battery in parallel with a completely discharged battery pack (the number of single cells is the difference between the total number of batteries in the battery bar and the number of batteries in series, and the single cell needs to be fully charged).

Judgment

➢ The sample must not catch fire during the test, and there must be no chemical leakage caused by sample rupture during the test sample.

-Battery Pack Component Temperature Test & 13B Battery Pack Surface Temperature Test

Test method

➢ Output discharge temperature rise test: Use a resistor as a load and control the discharge current at the maximum discharge current without overcurrent protection until thermal stability or the voltage will reach the minimum voltage one of the phenomena and cannot exceed the temperature limit value in the following chart.

➢ Charging test: Charge the battery with the maximum charging voltage, the charging current should not exceed the maximum charging current or circuit protection current until thermal stability or the battery is fully charged one of the phenomena and the temperature limit in the table below should not be exceeded.

-Battery Crush Test

Test methods

➢ The battery pack needs to withstand a maximum force of 13KN (achieved with a hydraulic machine), and the battery must not catch fire or explode during the test.

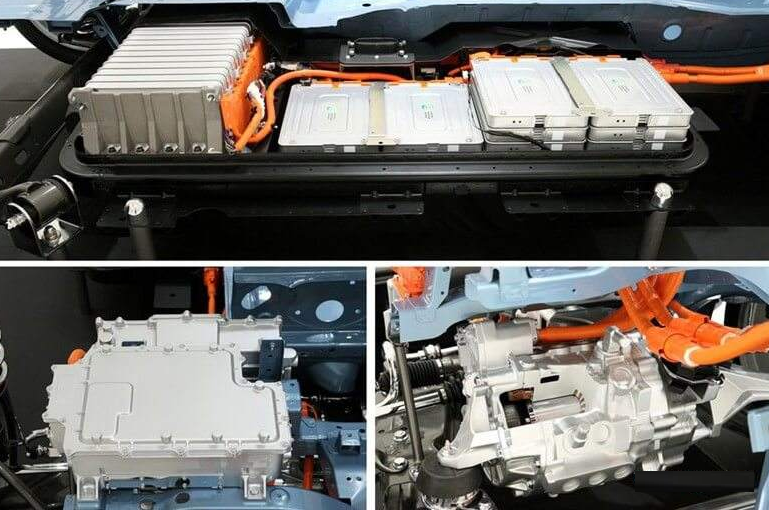

International Test Standards for Power Lithium Batteries

With the development of lithium-ion battery systems for electric vehicles, large energy storage and high rate energy storage, the original UL1642 and UL2054 can no longer fully reflect the safety performance of these large lithium-ion battery packs, so gradually new international standards have emerged, the following is the relevant information compiled by SES Power for you.

International standards bodies are mainly the International Electrotechnical Commission (IEC), the International Organization for Standardization (ISO), Underwriters Laboratories (UL), the American Society of Automotive Engineers (SAE) and the European Union and other relevant agencies.

-International standards

The power lithium-ion battery standards issued by IEC mainly include IEC 62660-1:2010 "Lithium-ion power battery monoblock for electric road vehicles Part 1: Performance test" and IEC 62660-2:2010 "Lithium-ion power battery monoblock for electric road vehicles Part 2: Reliability and abuse test".

UN 38. 3 "United Nations Recommendations on the Transport of Dangerous Goods, Standard and Test Manual" issued by the United Nations Transport Committee, the requirements for lithium battery testing are for the safety of the battery during transportation.

ISO in the power of lithium-ion batteries developed standards are ISO 12405-1: 2011 "Electric drive vehicles - - Lithium-ion power battery pack and system test procedures Part 1: High power applications", ISO 12405-2: 2012 "Electric drive vehicles --Lithium-ion power pack and system test procedures Part 2: High energy applications" and ISO 12405-3:2014 "Electric drive vehicles --Lithium-ion power pack and system test procedures Part 3: Safety requirements", respectively For high power type battery, high energy type battery and safety performance requirements, the purpose is to provide the vehicle manufacturers with optional test items and test methods.

-American Standard

UL 2580:2011 "Battery for Electric Vehicles" mainly assesses the reliability of battery abuse and the ability to protect personnel in case of abuse hazards, and the standard was revised in 2013.

SAE has a large and complete standard system in the automotive field. 2009 SAE J2464: 2009 "Safety and Abuse Testing of Rechargeable Energy Storage Systems for Electric and Hybrid Electric Vehicles" is an early manual for abuse testing of automotive batteries used in North America and worldwide, which clearly points out the scope of each test item and the data to be collected, and also gives recommendations on the number of samples required for the test items. It also provides recommendations on the number of samples required for the test items.

SAE J2929: 2011 "Safety Standard for Electric and Hybrid Battery Systems" was issued in 2011, which is a safety standard proposed by SAE based on the summary of various power battery related standards issued before, and consists of two parts: testing for routine conditions and testing for abnormal conditions that may occur during the driving process of electric vehicles.

SAE J2380: 2013 "Vibration Test of Electric Vehicle Battery" is a more classic standard for vibration test of electric vehicle battery, based on the statistical results of vibration load spectrum collection of actual vehicle road driving, the test method is more in line with the actual vehicle vibration situation and has important reference value.

-Other organizations standards

The U.S. Department of Energy (DOE) is mainly responsible for energy policy development, energy industry management and energy-related technology research and development, etc. In 2002, the U.S. government established the "Freedom CAR" (Freedom CAR) project, has issued a Freedom CAR power-assisted hybrid electric vehicle battery test manual and electric and in 2002, the U.S. government established the Freedom CAR program, which issued the Freedom CAR power-assisted hybrid electric vehicle battery test manual and the abuse test manual of energy storage systems for electric and hybrid vehicles.

The German Association of the Automotive Industry (VDA) is an association formed in Germany to unify various standards for the domestic automotive industry. The standards promulgated include VDA 2007 "Battery System Testing for Hybrid Electric Vehicles", which focuses on the performance and reliability testing of lithium-ion battery systems for hybrid electric vehicles.

The European Economic Commission (ECE) R100.2 "Uniform provisions for the approval of vehicles with regard to the special requirements of electric vehicles" is a specific requirement formulated by ECE for electric vehicles, which is divided into two parts: the first part regulates the vehicle in four aspects, such as motor protection, rechargeable energy storage system, functional safety and hydrogen emission, etc. The second part is a new safety and reliability requirement for rechargeable energy storage system.

What certificates are needed to ship lithium-ion batteries?

Any item needs to be transported, and lithium-ion batteries are no exception. However, because lithium-ion batteries have a certain degree of danger, so the international air transportation, ocean transportation and land transportation for lithium-ion batteries have made detailed regulations.

First of all, we must test and certify lithium-ion batteries to UN38.3.

UN38.3 refers to the United Nations for the transport of dangerous goods specifically formulated in the United Nations Manual of Tests and Criteria for the Transport of Dangerous Goods, Part 3, paragraph 38. 3, which requires that before transporting lithium batteries, they must pass a high degree of simulation, high and low temperature cycles, vibration test, impact test, 55 ℃ external short circuit, impact test, overcharge test, forced discharge test, in order to ensure the safety of lithium battery transport. If the lithium battery is not installed with the equipment, and each package contains more than 24 cells or 12 batteries, it must also pass the 1.2m free fall test.

-Product range

➢ All kinds of lead-acid batteries (such as automotive starter lead-acid batteries, fixed lead-acid batteries, small valve-regulated sealed lead-acid batteries, etc.)

➢ Various power secondary batteries (such as power car batteries, electric road car batteries, electric tool batteries, hybrid car batteries, etc.)

➢ All kinds of cell phone batteries (such as lithium-ion batteries, lithium polymer batteries, nickel-hydrogen batteries, etc.)

➢ Various small secondary batteries (such as laptop batteries, digital camera batteries, camcorder batteries, various cylindrical batteries, wireless communication batteries, portable DVD batteries, CD and MP3 player batteries, etc.)

-Test standards

UN38.3 test items and determine the test passing criteria

➢ Height Simulation Test

Under the conditions of pressure ≤ 11.6kPa, temperature 20±5℃, kept for more than 6 hours, no leakage, exhaust, disintegration, rupture, burning.

➢ Thermal test

High and low temperature impact test at 72 ± 2 ℃ and -40 ± 2 ℃ conditions, storage time in the limit temperature ≥ 6h, high and low temperature conversion time ≤ 30min, impact 10 times, room temperature (20 ± 5 ℃) stored for 24h, the total test time of at least one week.

➢ Vibration Test

15min from 7Hz to 200Hz to complete a reciprocal logarithmic sweep sine vibration, 3h to complete 12 vibrations in the three-dimensional direction.

Logarithmic sweep frequency is: from 7 Hz to maintain the maximum acceleration of 1gn until the frequency reaches 18 Hz. Then the amplitude is kept at 0.8 mm.

(Total offset of 1.6 mm) and increase the frequency until the maximum acceleration reaches 8 gn (frequency of about 50 Hz). Hold the maximum.

acceleration is held at 8gn until the frequency is increased to 200 Hz.

➢ Shock Test

150g, 6ms or 50g, 11ms half-sine shocks, 3 times in each mounting direction, 18 times in total.

➢ External short circuit test

Short-circuit at 55±2℃, external resistance <0.1Ω, the short-circuit time lasts until 1h after the battery temperature returns to 55±2℃.

➢ Crash Test

A 9.1kg weight is dropped on the battery with 15.8mm round bar from a height of 61±2.5cm, and the surface temperature of the battery is detected.

➢ Overcharge Test

Under the condition of 2 times the maximum continuous charging current and 2 times the maximum charging voltage, the battery is overcharged for 24h.

➢ Forced discharge test

The battery is connected to 12V DC power supply in series and forced to discharge with the maximum discharge current.

- Judgment Test Passing Criteria

(a) in the test T.1 to T.6, no disintegration or fire.

(b) in test T.1, T.2 and T.5, the effluent is not toxic, flammable or corrosive substances.

1> No outgassing or leakage was observed visually.

2> No exhaust or leakage resulting in weight loss in excess of that shown in Table 38.3.4.7.1.

(c) In tests T.3 and T.6, the effluent is not a toxic or corrosive substance.

1> visual observation did not see exhaust or leakage.

2>No exhaust or leakage resulting in weight loss in excess of that shown in Table 38.3.4.7.1.

- Packaging requirements

1. Unless installed in equipment (such as installed in cell phones, cameras, walkie-talkies, notebook computers, etc.), the battery and the original battery must be packaged separately to prevent short circuit, and in a strong outer packaging.

2. Unless installed in the equipment, each package contains more than 24 original batteries or 12 batteries, must also meet the following requirements.

a)Each package must be marked to indicate the lithium batteries contained and the special measures to be taken when the package is broken.

b)Each shipment must be accompanied by documentation to indicate that the packaging contains lithium batteries and special measures to be taken when the packaging is broken.

c)Each package must be able to withstand a drop test of 1.2m in any orientation without damaging the battery or cell in the package and without changing the position of the battery so that the battery and the battery (or the original battery and the original battery) are in contact with each other and no battery leaks out of the package.

d)Unless the lithium battery is installed in the equipment, the gross weight of each package shall not exceed 30kg.

The difference between the latest version of UN38.3 and older versions

The new version of UN38.3 is compared with the original version Rev.4-2003, the main changes in the new version are as follows.

1. There are obvious changes to the definition of large batteries and cells.

Rev.4 defines a large battery as a battery with a total lithium content of more than 500g in the anode in a fully charged state. Large cells refer to cells with anode lithium content or lithium equivalent content greater than 12g when fully charged.

The new version Rev.5 defines large cells as lithium metal or lithium ion cells with a total weight greater than 12kg. Large cells are defined as: for lithium metal cells, cells with anode lithium content greater than 12g when fully charged; for lithium ion cells, cells with rated watt-hour greater than 150Wh.

2. The definition of lithium equivalent content in the original version is cancelled in the new version Rev.5.

For lithium-ion batteries and cells, it is changed to use the rated watt-hour data to indicate that the rated watt-hour is defined as the product of the rated capacity of the battery (cell) and the rated voltage.

3. Compared with Rev.4, the new version of Rev.5 contains no change in the test items and test methods, determination criteria, etc., but the number and state of the battery or cell required by each test item has changed significantly, mainly as shown in the following table.

Although the number of test samples and the state of the cells have been changed relatively significantly in the new version, the test scheme and method have not changed, and the main test process has not changed, so there will be no significant changes in the test cycle when the new version is implemented.

Will MSDS affect the shipping and sales of lithium-ion batteries?

MSDS (Material Safety Data Sheet) is a document used by chemical manufacturers and importers to clarify the physical and chemical properties of chemicals (such as PH value, flash point, flammability, reactivity, etc.) and the possible hazards to the health of users (such as carcinogenic, teratogenic, etc.).

This is a certificate often required for the transport and sale of lithium-ion battery products, as it is a guarantee of environmental protection and safety.

In European countries, Material Safety Technical/Data Sheet MSDS is also known as Safety Technical/Data Sheet SDS (Safety Data Sheet). The International Organization for Standardization (ISO) uses SDS terminology, however, the United States, Canada, Australia, and many Asian countries use MSDS terminology.

MSDS is a comprehensive legal document about the characteristics of a chemical that a chemical manufacturer or distributor is required by law to provide to its customers. It provides sixteen contents such as physical and chemical parameters, combustion and explosion properties, health hazards, safe use and storage, spill disposal, first-aid measures and relevant laws and regulations of chemicals.

MSDS can be prepared by manufacturers themselves according to the relevant rules. However, in order to ensure the accuracy and standardization of the report, it is recommended to apply to professional organizations for preparation.

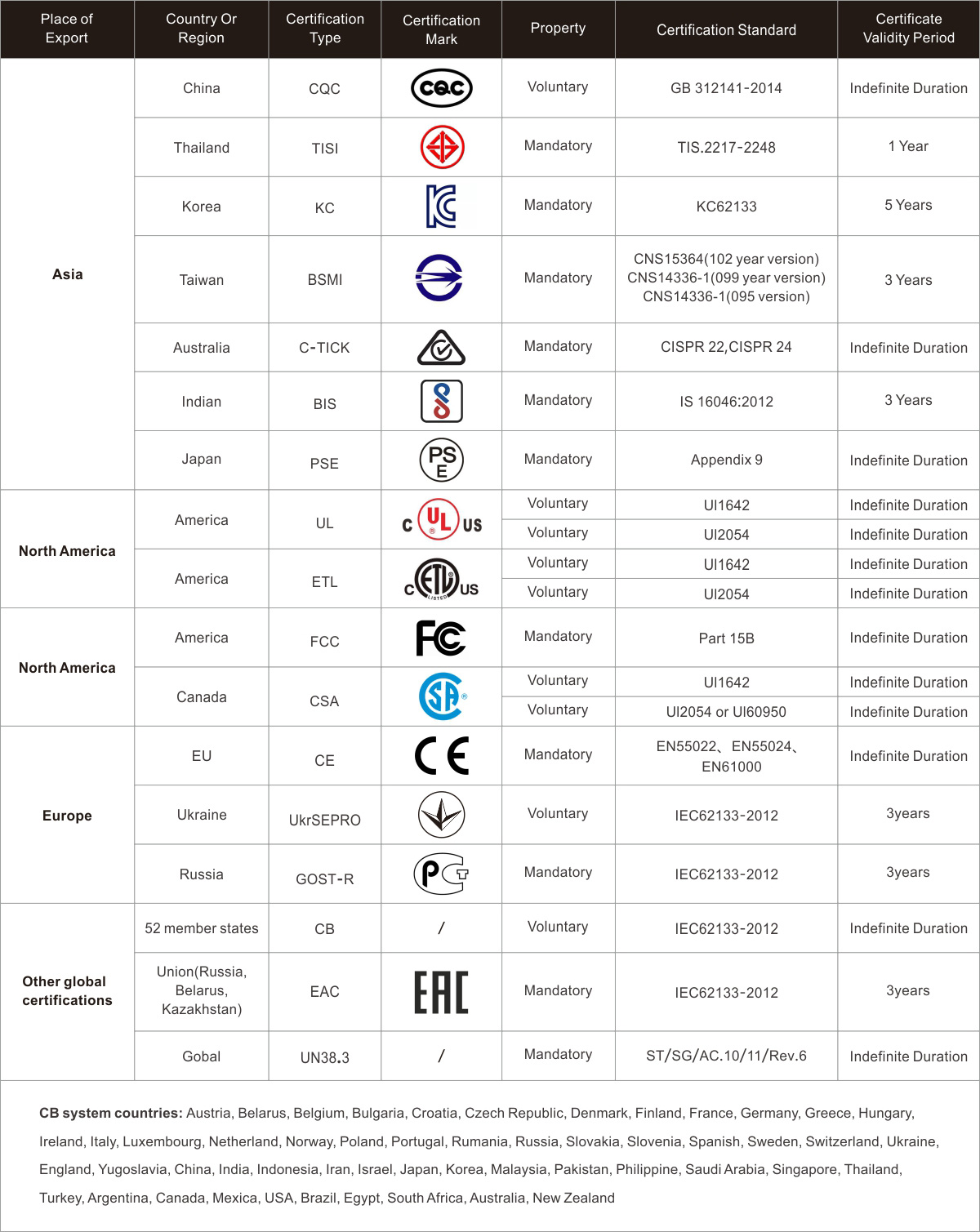

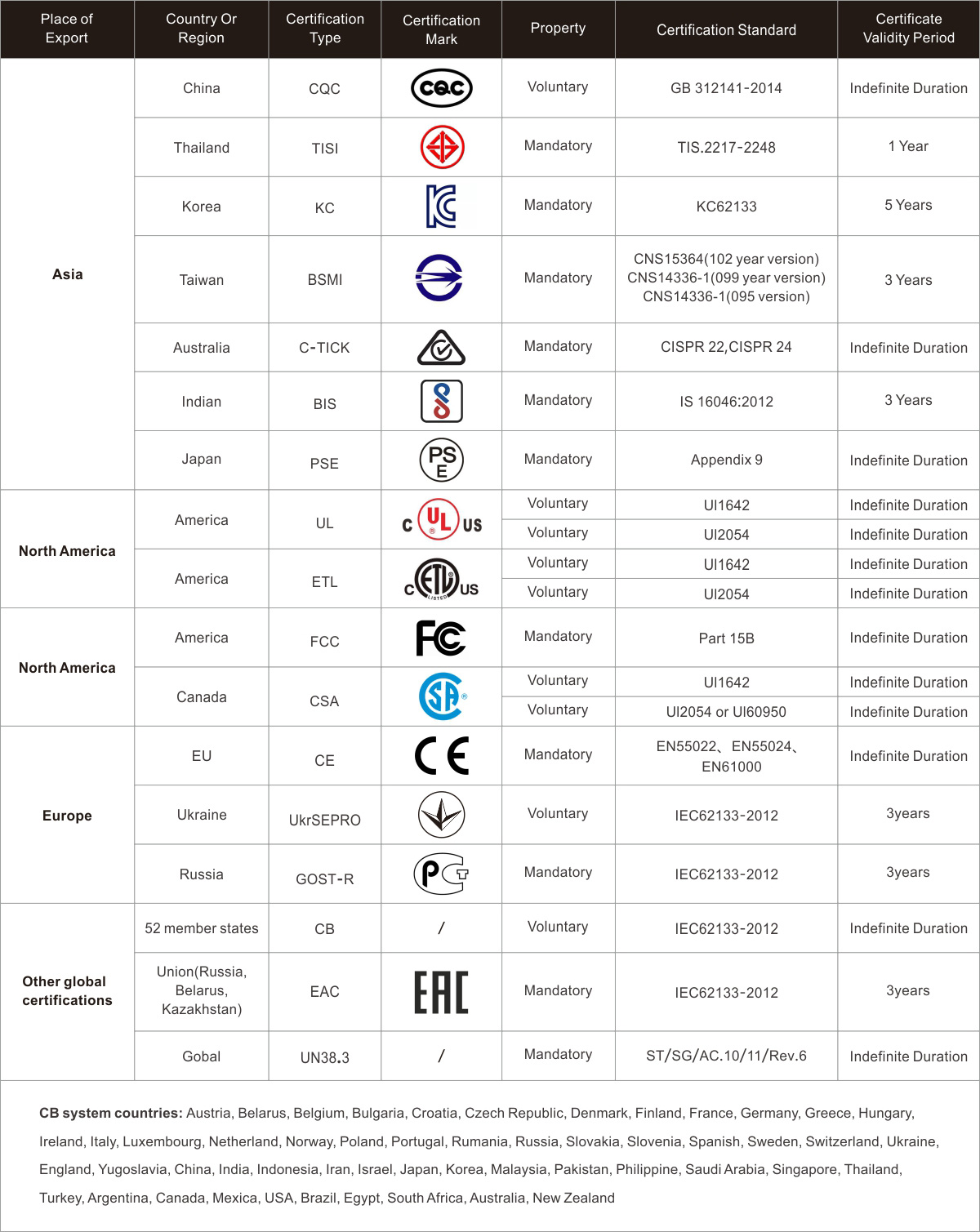

Global Certification and Test Standard for Lithium-ion Batteries

SES Power has explained the main certification and testing standards for lithium-ion batteries, but each country and region has different perceptions and requirements for lithium-ion batteries, resulting in some countries having the same standards, and some countries making a certification and testing standard specifically for themselves. The following are Certification Details of Major Global Countries and Regions (Battery)

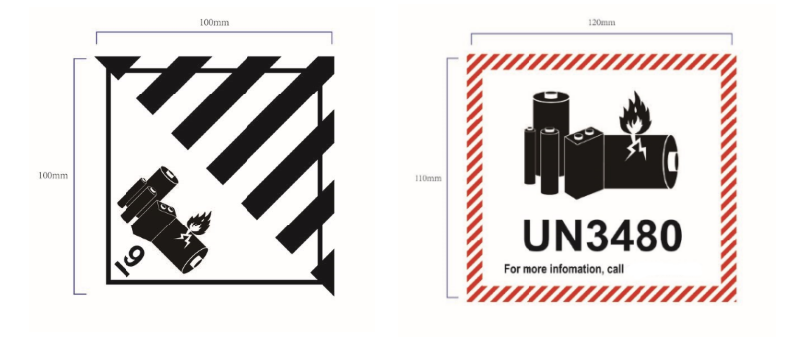

Lithium Ion Battery Transportation

Lithium batteries can be transported by air, ship or car and train. Air and ocean freight are most commonly used. Because lithium is a metal that is particularly susceptible to chemical reactions and combustion, improper packaging and transportation of lithium batteries can lead to combustion and explosion.

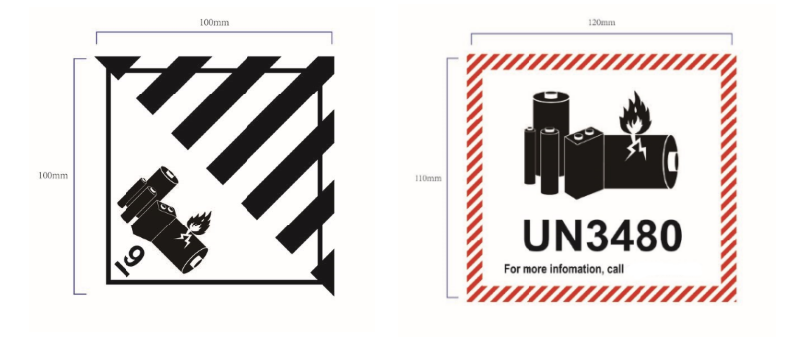

-Lithium Ion Battery Package Requirements

➢ In UN packages that meet the DGR hazardous material specification. The package should show the appropriate number.

➢ Proper use of the 9 hazard labels.

➢ Complete the Dangerous Goods Declaration and provide the relevant Dangerous Goods Packaging Certificate.

-Lithium Ion Battery Transportation Requirements

➢ Batteries should meet UN 38.3 testing requirements and pass a 1.2m height drop test on the package.

➢ Provide a dangerous goods declaration document with UN number.

➢ Batteries should be protected from short circuit. Especially in the same package to prevent short-circuiting of conductive materials.

➢ To avoid severe vibration during transition, use corner armor on all vertical and horizontal edges of the tray.