What is a lithium-ion battery?

"Lithium-ion battery", is a type of battery that is made of lithium metal or lithium alloy as anode material and uses a non-aqueous electrolyte solution. Lithium-ion batteries can be broadly divided into two categories: lithium metal batteries and lithium-ion batteries. Lithium-ion batteries do not contain lithium in its metallic state and are rechargeable.

(scientists won the Nobel Prize for lithium-ion batteries)

The history of lithium-ion batteries

➢ 1912 lithium metal batteries were first proposed and studied by Gilbert N. Lewis.

➢ In the 1970s, M. S. WhitTIngham proposed and began to study lithium-ion batteries

➢ 1980, J. Goodenough discovered that lithium cobaltate can be used as the cathode material for lithium-ion batteries

➢ In 1992, Sony Corporation of Japan invented the lithium-ion battery with carbon material as the negative electrode and lithium-containing compound as the positive electrode, during the charging and discharging process, no lithium metal exists, only lithium ions, which is the lithium-ion battery.

➢ In 1998, a large number of prismatic lithium-ion batteries were put into the market, occupying a large share of the market.

➢ In 1998, a large number of prismatic lithium-ion batteries were put into the market, occupying a large share of the market. In 1998, square lithium-ion batteries and cylindrical lithium ion batteries were finally used in a large number of different electronic products after years of settling.

➢ In 1999, China began the first attempt to mass-produce lithium-ion batteries.

➢ In 2022, lithium-ion battery has penetrated into our life in all aspects, it is ubiquitous, once leaving it, human activities will be unimaginable collapse.

The application of lithium-ion batteries

Consumer Electronics

We can't live without lithium-ion batteries in our daily use of consumer electronics, such as smartphones, razors, hair clippers, laptops, portable power supplies, apple's smart watches, electric toys, and more.

These applications require higher capacity, smaller size, and better safety for lithium-ion batteries. So, lithium polymer batteries, 18650 cylindrical lithium-ion batteries, lithium iron phosphate ion batteries are preferred.

Industrial Field

It is very wide field and various application conditions are totally different. The main applications are electric vehicles, photovoltaic energy storage, UPS, data centers, large power tools, railroad infrastructure, security and communication, exploration and mapping, etc.

The requirements of these applications for lithium-ion batteries are higher safety, the best cost performance, longer life, etc. So, lithium-iron phosphate ion batteries, lithium polymer batteries, ternary lithium-ion batteries are preferred.

For example, energy storage systems, will generally use a single cell capacity as high as 100ah LFP batteries.

Special occasions (Customized)

Generally speaking, special occasions refer to very demanding application environments, such as lithium-ion batteries that can be used normally below -40 degrees Celsius, or up to 80 degrees Celsius, or that with a service life of up to 10 years, or with a discharge rate of up to 10C or even 50C.

The main scenario lies in the fields of weapons, R&D equipment, polar expeditions, military, ships, aircraft, high energy physics, etc. The common ones are ultra-low temperature lithium-ion batteries, high temperature lithium-ion batteries, lithium-ion titanate batteries and explosion-proof lithium-ion batteries

SES Power has rich experience in this field, and customers are welcome to refer to our related webpage, or contact us directly for customization.

Types of lithium-ion batteries

Shape

-Cylindrical

Cylindrical lithium-ion battery, in fact, the cylindrical means that this lithium-ion battery is shaped like a stick-like form. This is a very visual description.

Cylindrical lithium-ion batteries generally use 5 digits as its name. For example, 18650 cylindrical lithium-ion battery, 18 refers to its diameter of 18mm, 65 refers to its height of 65mm, as for the last number 0, refers to its shape is round.

Common models on the market are: 14500 (NiMH AA number), 18500 (NiMH A number), 18650, 21700, 26650, 26700, 32650 (32700).

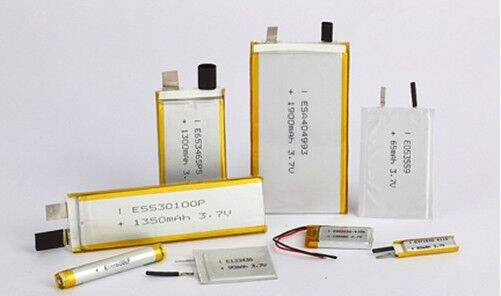

-Lithium polymer battery Li-polymer

The Li-polymer battery is wrapped in a paper-like aluminum-plastic film. Its form is completely different from that of a cylindrical lithium-ion battery, but a thin square.

Li-polymer batteries are ultra-thin and can be made in any shape and capacity to suit the needs of various products. The minimum thickness that can be achieved by this type of battery is up to 0.5mm. because of this feature, resulting in the lithium polymer battery market has almost no universal models, usually custom-made.

- Square lithium-ion battery.

The square lithium-ion battery is wrapped in a square aluminum case. The appearance of the square lithium-ion battery presents a very heavy state, as a brick.

The biggest feature of the square lithium-ion battery is that the capacity of the single cell can be made very high, 100ah is already its most common standard.

Case

-Steel Case

Steel Case has a long history of application in the field of lithium-ion batteries and is the most commonly used accessory for cylindrical lithium-ion batteries. the advantage of Steel Case is that the equipment and process are very mature, the production volume is also very large, and the cost is low, but the disadvantage is low safety and heavy weight. In order to solve the problem of safety, many manufacturers increase battery safety performance by optimizing the design structure by safety valve, PTC and other devices.

-Aluminum Case

Aluminum case is lighter and safer than Steel Case, but the cost has also increased. The aluminum case is usually a square, and the size has not yet formed a uniform standard in the industry.

SES Power has applied large-capacity Aluminum Case Lithium-Ion Battery in many industrial batteries.

-Pouch cell

Pouch cell has the advantages of light weight, low mould cost and high safety. But it has the highest material cost and production cost.

PS: If you are interested in knowing more about these types of Li-ion batteries and want to know more about them, you can click on SES Power's link xxxx.

-Anode Materials

The names we usually say for lithium-ion cobalt-acid batteries, ternary lithium-ion batteries, lithium-iron phosphate batteries, lithium-ion carbonate batteries, and so on, are all based on the cathode material inside the battery. Here are the common cathode materials and their comparison.

A:LiCoO2 battery

The chemical formula for lithium cobalt oxide is LiCoO₂. It is a kind of inorganic compounds, and it contains Co, a precious metal.

B:LiMn2O4 battery

The chemical formula is LiMn2O4, which was first used in lithium-ion batteries by Hunter in 1981.

C:LiFePO4 Battery

The chemical formula is LiFePO4 (LFP for short). Compared with the traditional lithium-ion secondary battery cathode material, LiFePO4 has a wider source of raw materials, lower price and no environmental pollution.

D:NCM (Ternary) Battery

The chemical formula is Li(NiCoMn)O2. Materials that are more balanced in terms of capacity and safety have better cycle performance than conventional lithium cobalt oxide.

The material characteristics of the anode of lithium ion battery are compared as follows:

Item | LiCoO2 | LiNiCoMnO2 (ternary) | LiMn2O4 | LiFePO4 |

Compacted Density (g/cm3) | 2.8~3.0 | 2.0~2.3 | 2.2~2.4 | 1.0~1.4 |

Specific Surface Area (m2/g) | 0.4~0.6 | 0.2~0.4 | 0.4~0.8 | 12~20 |

Volume (mAh/g) | 135~140 | 140~180 | 90~100 | 130~140 |

Voltage Platform (V) | 3.7 | 3.6 | 3.7 | 3.2 |

Cycle Performance | ≥500times | ≥500times | ≥300times | ≥2000times |

Safety Performance | bad | good | better | best |

Scope of Application | small and medium size battery | small batteries/small

power battery | power battery

low cost battery | power battery/power

supply with super capacity |

Key parameters of lithium-ion batteries

Voltage

-Nominal Voltage

The potential difference between the anode and cathode of lithium ion battery is called the nominal voltage of lithium ion battery. The nominal voltage is determined by the electrode potential of the electrode material and the concentration of the internal electrolyte.

-Open Circuit Voltage

Open Circuit Voltage represents the voltage difference between the positive and negative terminals on the outside of the Li-ion battery when it is in the open circuit state.

-Operating Voltage

Operating Voltage represents the voltage of the lithium-ion battery at the normal load time, which is actually the voltage of the lithium-ion battery in the working state.

-Recommended Commonly Used Voltage

12V Lithium Ion Battery

24V Lithium Ion Battery

36V Lithium Ion Battery

48V Lithium Ion Battery

**SES Power offers lithium-ion battery products in different voltage bands, and they are widely used in different fields.

-Capacity

Capacity is one of the important indicators to measure the performance of lithium-ion batteries. It means that under certain conditions (discharge rate, temperature, termination voltage, etc.), the total amount of power discharged from a lithium-ion battery (professional equipment is required to record it), which called “capacity”. The simplest meaning of 10Ah lithium-ion battery is this lithium-ion battery can be discharged continuously with 10A current for 1 hour.

-Internal Impedance

For lithium-ion batteries, the internal resistance of the battery is divided into ohmic internal resistance and polarized internal resistance. Ohmic internal resistance is composed of electrode material, electrolyte, diaphragm resistance and contact resistance of each part. Polarization internal resistance is the resistance caused by polarization during electrochemical reaction, including the resistance caused by electrochemical polarization and concentration polarization.

The actual internal resistance of the lithium-ion battery is the resistance to the flow of current through the interior of the battery when it is in operation. Large internal resistance of the battery (in the process of normal battery use) will generate a lot of Joule heat (according to the formula: E=I^2RT) causing the battery temperature to rise, resulting in lower battery discharge working voltage and shorter discharge time, causing serious impact on battery performance and life.

The precise calculation of the size of the internal resistance of the battery is quite complicated, and it will change continuously during the use of the battery. Experience shows that the larger the volume of lithium-ion batteries, the smaller the internal resistance; and vice versa

-Cycle life

Standard cycle life refers to the number of cycles a lithium-ion battery can withstand before its capacity decays to a specified value (generally defined as 80% of initial capacity for lithium-ion batteries) under certain charge and discharge conditions (such as charge voltage, charge current, discharge cut-off voltage, discharge current, and ambient temperature).

One cycle: one full charge + one full discharge.

Note: LFP battery has good cycle characteristics and can maintain about 80% capacity after 2000-4000 cycles.

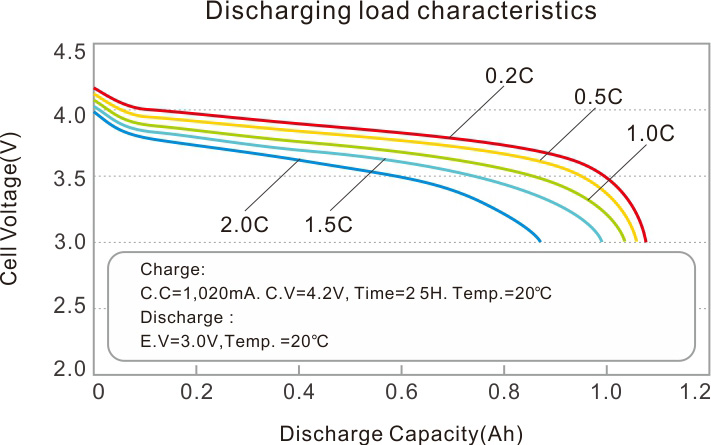

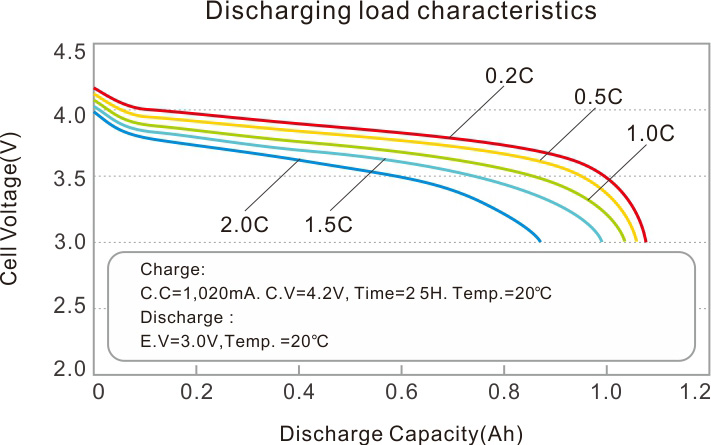

-Discharge Rate

Discharge rate refers to the current of lithium ion battery during discharge, which is generally expressed as C. The formula is as follows:

Discharge Rate = Discharge Current/Rated Capacity

The general energy type lithium-ion battery discharge rate is 1C-3C, and the high-rate (high-C) type lithium-ion battery is 5C-50C.

SES power's low-temperature lithium-ion batteries are capable of discharging at a normal 5C discharge rate at -40 degrees C under DOD 60%.

Note: Because lithium battery has organic solvent electrolytes, the conductivity is typically only a few hundredths of that of lead-acid or alkaline battery electrolytes. Therefore, when the lithium battery is discharged at a high current, it is too late to replenish Li+ from the electrolyte, which make the voltage reduce.

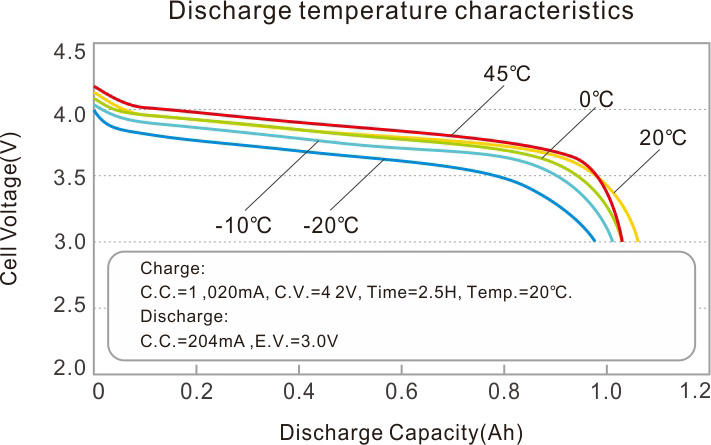

-Operating Temperature

It refers to temp of the charging and discharging environment that lithium ion battery can adapt to.

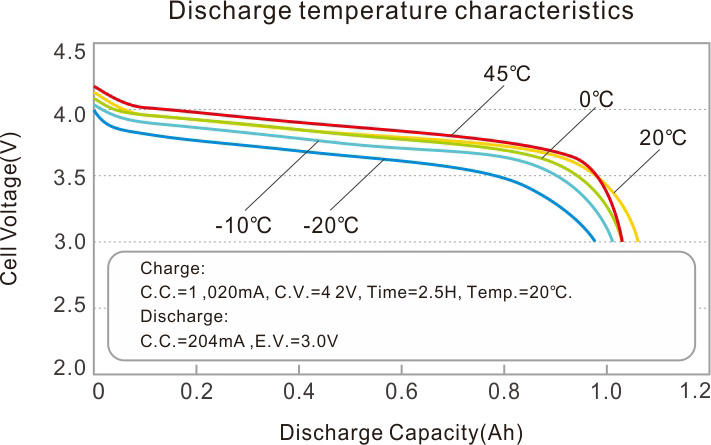

When lithium ion battery is at low temperature, the discharge platform has a certain reduction; When the temperature is high, the circulation performance of the battery will be affected, and the battery will slightly swell. Therefore, the battery is generally recommended to operate at 0℃ - 40℃.

Low Temperature Discharge Characteristic Curve of Lithium Ion Battery

-Self-discharge rate and store characteristics

Self-discharge rate, also known as charge retention capacity, refers to the ability of the battery to retain the charge stored in the battery under certain conditions in the open circuit state. It is mainly affected by the battery manufacturing process, materials, storage conditions and other factors. Self-discharge rate is an important parameter to measure battery performance.

Store Characteristics is a visual representation of self-discharge rate, in addition to the performance of the cell itself, mainly reflects the impact of storage environment temperature on lithium-ion batteries.

The self-discharge rate of Li-ion battery is excellent, usually 2%/M, NiMH battery is 30%/M, and lead-acid battery is 25%/M.

High Temperature Discharge Characteristic Curve of Lithium Ion Battery

Differences between Lithium Ion Battery and Lead Acid Battery, NI-MH Battery

In fact, lead-acid batteries and nickel-hydrogen batteries appeared much earlier than lithium-ion batteries, for example, lead-acid batteries were used in large quantities a hundred years ago, and nickel-hydrogen batteries dominated in the 1980s and 1990s.

Lithium-ion batteries actually appeared as the successor of lead-acid batteries and nickel-hydrogen batteries, because although lead-acid batteries and nickel-hydrogen batteries are also secondary batteries, their chemical composition has determined their basic performance. With the development of technology and the increasingly demanding needs of human beings, lithium-ion batteries were created in this context.

But there is no denying that lithium-ion batteries also have a lot of problems, although lithium-ion batteries have occupied a lot of lead-acid batteries, nickel-hydrogen batteries market, especially to perfectly replace the lead-acid battery lithium iron phosphate ion battery appeared, but the complexity and inertia of the market, making lead-acid batteries, nickel-hydrogen batteries and a wide range of markets.

Below we briefly compare lithium-ion batteries, lead-acid batteries, nickel-hydrogen batteries, so that you can have a very intuitive impression.

Item | Lithium Ion Battery | Lead Acid battery | NI-MH Battery |

Energy Density (wh/kg) | 200~260wh/kg | 50~70wh/kg | 40~70wh/kg |

Open Circuit Voltage (v) | 3.6V | 2.0V | 1.2V |

Cycle Life (Times) | 300-4000 | 400-600 | 300-350 |

Charging Speed | Quick

| Slow | Slower |

Memory Effect | No | No | Yes |

Environmental Performance | Lower Pollution | High Pollution | Low Pollution |

Safty | low | high | high |

Self-discharge rate | 2%/M | 25%/M | 30%/M |

Price | High | Low | Middle |

Best Lithium Ion Battery Brand

- Cylindrical Lithium Ion Battery Brand

There are numerous models of cylindrical lithium-ion batteries, among which 18650 cylindrical lithium-ion batteries are the most common, and the famous brands are

• Japan: SANYO/Panasonic, SONY, etc.

• South Korea: LG, Samsung, etc.

• China: BAK, LISHEN, SES POWER, etc.

Panasonic

Founded: 1918

Headquarters: Osaka, Japan

Panasonic's power battery business belongs to the energy sector of the AIS segment, which includes secondary batteries and energy equipment. Secondary battery equipment includes Panasonic's Secondary Battery Division and Tesla Division, which will significantly affect Panasonic's earnings growth.

SONY

Founded: 1946

Headquarters: Japan

Founded in May 1946, Murata is one of the world's largest manufacturers of electronic products and a pioneer in the lithium battery industry. In July 2016, Murata acquired Sony's battery division. Now, Sony is preparing to enter the field of electric vehicle batteries.

LG Chem

Founded: 1947

Headquarters: Korea

This is a subsidiary of LG Group, a leading Korean chemical company engaged in the production of petrochemicals, batteries, advanced materials and life science products. It dominates the global market in the fields of automotive batteries, ESS batteries and mobile device batteries.

Samsung SDI

Established: 2011

Headquarters: South Korea

This is a subsidiary of Samsung Group in Korea, mainly engaged in display and lithium battery production. Samsung SDI R&D centers are located in Korea, Japan, Russia and other countries, and has offices in Taiwan, Germany, Malaysia, India, Vietnam, etc. It is one of the top 100 lithium battery manufacturers in the world.

LISHEN

Established: 1997

Headquarters: Tianjin, China

Tianjin Lishen Battery Co., Ltd, the representative brand of lithium battery in China, is one of the professional manufacturers of lithium battery with large investment and highest technology level in China.

BAK

Established: 2001

Headquarters: Shenzhen, China

Shenzhen BAK Technology Co., Ltd, a famous brand of lithium battery, supplier of batteries for HP, Dell, Lenovo, etc., is a global famous lithium battery manufacturer integrating R&D, production and sales.

SES POWER

Established: 2012

Headquarter: Dongguan, China

Dongguan Zhilian New Energy Co., Ltd. is the top lithium-ion battery and lithium-ion battery pack manufacturing factory in China, which is mainly engaged in the special lithium batteries, low-temperature batteries, explosion-proof batteries, high-rate power lithium-ion battery, lithium-ion battery energy storage system, home energy storage system and medical lithium batteries.

- Polymer Battery Brand

•Japan: Panasonic, SONY, etc.

•South Korea: LG, Samsung, etc.

•China: Farasis Energy, ATL,SES POWER, etc.

Farasis Energy

Founded: 2009

Headquarters: Jiang’xi, China

VN Technology's core product is the core product ternary soft pack power battery, focusing on the development, production and sales of new energy vehicle power battery systems and energy storage systems. VN Technology has been the No. 1 soft pack power lithium-ion battery shipper in China for five consecutive years from 2017-2021.

Amperex Technology Ltd. (ATL)

Founded: 1999

Headquarters: Dongguan, China

ATL is a wholly owned and independently operated company under the TDK Group in Japan, with over 10,000 employees. With annual sales of more than RMB 30 billion, ATL ranks among the top ten in the world in the field of lithium-ion batteries and among the top in the world in the polymer lithium-ion battery industry.

-Prismatic Battery Brand

China:CATL,BYD,EVE,SES POWER, etc.

The main manufacturers of square lithium-ion batteries are currently concentrated in China.

CATL

Founded: 2011

Headquarters: NingDe, China

CATL focuses on the research, development, production and sales of new energy vehicle power battery systems and energy storage systems, with core technologies in the field of power and energy storage batteries, materials, cells, battery systems, battery recycling and other full industry chain development and manufacturing capabilities. The company is a global leader in shipments of power lithium-ion batteries.

BYD

Founded: 1995

Headquarters: ShenZhen, China

BYD has more than 220,000 employees and its business spans four industries: automotive, rail transportation, new energy and electronics, and is listed in both Hong Kong and Shenzhen, with revenue and market value exceeding US$20 billion. In the field of batteries, BYD has 100% independent research and development, design and production capacity, and its products have covered consumer 3C batteries, power batteries (lithium-ion iron phosphate batteries and ternary batteries), solar batteries, and energy storage batteries, and has formed a complete battery industry chain. Currently, BYD is the world's largest lithium-ion iron phosphate battery manufacturer in terms of production capacity.

EVE

Founded: 2001

Headquarters: Huizhou, China

EVE, with its boss in China, has the advantage of technology and production scale in the field of primary lithium-ion batteries such as lithium/thiocarbonyl chloride, lithium/manganese dioxide and lithium/iron disulfide, and is the world's largest major supplier of disposable lithium-ion batteries. In recent years EVE has fully transformed into secondary lithium-ion batteries, with breakthroughs in electric vehicles, large-scale energy storage systems, etc.

SES Power

Founded: 2012

Headquarter: Dongguan, China

SES Power has been committed to the promotion and application of square lithium-ion batteries, which are widely used in photovoltaic energy storage, large energy storage systems, intelligent lithium-ion energy storage systems, home energy storage, UPS, data centers, etc.

SES Power has been cooperating deeply with CATL, BAK, BYD, EVE, etc. in the lithium-ion battery industry.

How to choose the right lithium-ion battery

Compared with traditional secondary batteries such as lead-acid batteries and nickel-hydrogen batteries, lithium-ion batteries have very obvious advantages.

1. The high capacity of lithium-ion batteries can compress the battery space as much as possible, making portable appliances can be thinner and lighter, while the standby time is longer.

2. The cycle life of lithium-ion batteries is very long, ternary lithium-ion batteries generally have a cycle life of 500-1000 times, lithium iron phosphate batteries cycle life of up to 2000-4000 times, while the cycle life of lead-acid batteries generally only 300-500 times.

3. The output power of lithium-ion batteries is large, which is very important for equipment that requires high current discharge, such as models, drones need to do flips in the air, the battery power requirements are very high; or similar handheld power tools, need a long time large multiplier discharge; or electric golf carts need to climb the slope, lithium-ion batteries can cover these needs.

4. The self-discharge of lithium-ion batteries is low, and this characteristic is very important for designing some backup energy storage power in remote areas, which greatly reduces the cost of manual inspection and installation.

5. Lithium-ion batteries have a wide operating temperature range, and the lithium-ion battery packs made by SES Power can be charged and discharged normally from -60 to 85℃. It is very adaptable to the requirements of extremely cold and hot environment.

6. Unlike lead-acid batteries that contain lead, lithium-ion batteries are green and no longer pose a new burden on the environment.

There are very many types and different manufacturers of lithium-ion batteries on the market, so how to select the optimal and most suitable lithium-ion batteries? What aspects should we focus on?

First of all, we should be clear that lithium-ion batteries also have some shortcomings.

Lithium-ion batteries require high preparation conditions, which is a challenge for the management ability and cost control of manufacturers.

Secondly, lithium-ion batteries have higher energy density and increased safety risks.

In order to improve safety and prevent lithium-ion battery short-circuit overcharge, the pack of lithium-ion battery (e.g., more than 2 cells in series or parallel, according to customer requirements to form a specific shape, known as "pack".) They must be electronically monitored by a protection board or BMS.

-Be clear about your actual needs

Before choosing a lithium-ion battery, we must be very clear about the requirements of our electronic devices for lithium-ion batteries, such as voltage, capacity, size, discharge current size, ambient temperature, etc. This is a prerequisite for the correct selection of lithium-ion batteries.

-Battery Brand

Try to choose the internationally renowned lithium-ion battery manufacturer's cells, because the production of lithium-ion batteries is very complex, a little difference in the source will be in the final lithium-ion battery pack will be exponentially magnified form. Lithium-ion battery international famous brands are Panasonic, Sanyo, Samsung, LG, CATL, BYD, EVE, SES Power, etc.

Of course, the price of lithium-ion batteries from famous brands can be high, and SES Power has deep cooperation with these famous brands. It is able to take advantage of scale to reduce the procurement cost.

-Nominal Capacity

This is the core parameter, the size of the capacity also means that the price is high or low, we must choose the capacity that can meet the needs of the equipment, but also can save costs. Because the capacity determines the price, many unscrupulous manufacturers will deliberately exaggerate or deceive users on the nominal capacity, we try to choose brand-name batteries through regular channels, such as working with SES Power.

The unit of capacity is mAh or Ah. For example, a lithium-ion battery with a nominal capacity of 20ah is able to be used for 2 hours at 10a continuous discharge current.

-Charge-discharge Rate (C-rate)

Charge-discharge rate = charge-discharge current (A)/rated capacity (Ah)

The charge/discharge rate is the value of the current required for a battery to release its rated capacity within a specified time. It is numerically equal to the multiple of the rated capacity of the battery. The unit of battery discharge rate is generally C (short for c-rate), such as 0.5C, 1C, 5C, etc.

This parameter can also have a serious impact on price and performance. High rate Li-ion batteries are usually nearly twice as expensive as capacity Li-ion batteries, and the cycle life of high rate Li-ion batteries is nearly half that of capacity Li-ion batteries. It is usually motors, motors, UPS and other equipment that require high rate Li-ion batteries.

-Internal impedance

Internal impedance is the self-consumption of the battery. The lower the internal impedance, the better the discharge capacity. The internal resistance will be written in the general battery introduction page. Try not to buy batteries with internal resistance greater than 100mΩ.

The internal resistance of prismatic lithium-ion batteries is very low, usually less than 5 mΩ. The internal resistance of high-magnification lithium-ion batteries is also very low, because high current generation is required, and high internal resistance will lead to serious heat generation.

-Operating Temperature

Lithium-ion batteries are essentially chemical-based products, so temperature is a major factor affecting the performance and life of lithium-ion batteries. The most appropriate ambient temperature for a normal lithium-ion battery is 0-45 degrees Celsius. Too high a temperature can easily damage the performance of lithium-ion batteries. Of course, some custom lithium-ion batteries can operate normally at -40 degrees Celsius, or even -60 degrees Celsius.

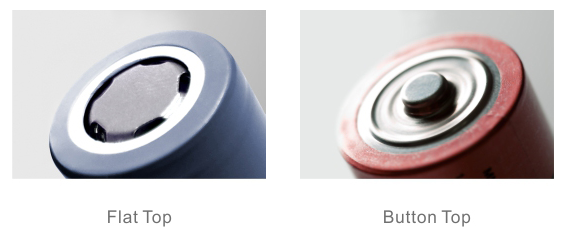

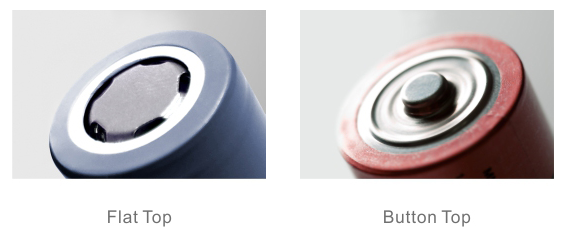

-Button Top and Flat Top

Cylindrical Li-ion batteries will have two kinds of distinction: flat top and button top. The flat top is mainly used in combination, and the button top is mainly used for individual use, such as flashlights, remote controls, and toys.

Li-ion batteries and Li-ion battery packs require PCM/BMS

Lithium-ion batteries have certain defects, in summary, there are the following aspects.

1. lithium iron phosphate ion batteries are safer, but lithium cobaltate as the cathode material of lithium-ion batteries are less safe.

2. Lithium-ion batteries are more sensitive to ambient temperature: if used in high temperature conditions, may cause combustion or even explosion; low temperature will lead to deterioration in the performance of lithium-ion batteries, affecting the performance and life of the battery.

3. Each cell's internal resistance, capacity, etc. will be different. After the long-term use of lithium-ion battery pack composed of multiple cells, these differences will be magnified, resulting in a sharp decline in the performance of the lithium-ion battery pack.

Therefore, the Li-ion battery must be equipped with PCM or BMS, both of which have the ability to protect the Li-ion battery. The difference is that the BMS has software functions for effective monitoring, protection, energy equalization and fault alarm, and communicates with the host computer via Bluetooth, RS485, Can2.0, Uart and other protocols.

Proper use of lithium-ion batteries

-Maintain at 30-50% of remaining capacity during storage

The benefit is to keep the lithium-ion battery internal chemicals in a stable state.

-Do not use at high or low temperatures

Too high a temperature or too low a temperature, will greatly reduce the actual life of lithium-ion batteries. The most suitable working temperature for lithium-ion batteries is 0-45 degrees Celsius.

-Avoid frequent deep charging and discharging

Although there is no memory effect of lithium-ion batteries, but frequent deep charge and discharge of lithium-ion batteries will produce some cumulative damage to the internal chemical structure. Keep 50-80% DOD use is a reasonable way to use.

-Avoid excessive high rate of charge and discharge

Often in the high rate of charge and discharge will lead to accelerated aging of the internal chemical substances of lithium-ion batteries. Lithium-ion batteries have a multiplier parameter in the manual, it is recommended not to exceed the range of this parameter when using.

-Appropriate charging or discharging

.When the lithium-ion battery is not used for a long time, the lithium-ion battery should be charged and discharged once in 3-6 months, which helps to maintain the chemical activity of the lithium-ion battery.

-Avoid mixing and matching different sizes of lithium-ion batteries

This is very important, because different types, different specifications of lithium-ion batteries actually vary greatly, without making a distinction and testing on the mixed use, it is likely to lead to a serious decline in battery performance, and even the risk of fire, explosion.

The correct use of lithium-ion batteries to make the performance of lithium-ion batteries to give full play to the life of the battery will also be extended.