12V lithium battery for replacing lead-acid is on a larger scale, Tesla, BMW, BYD have all accelerated the pace

I recently talked to a friend that 2022 may be a very important time point for starting battery development: marking the replacement of lead-acid batteries by 12V lithium batteries on a larger scale.

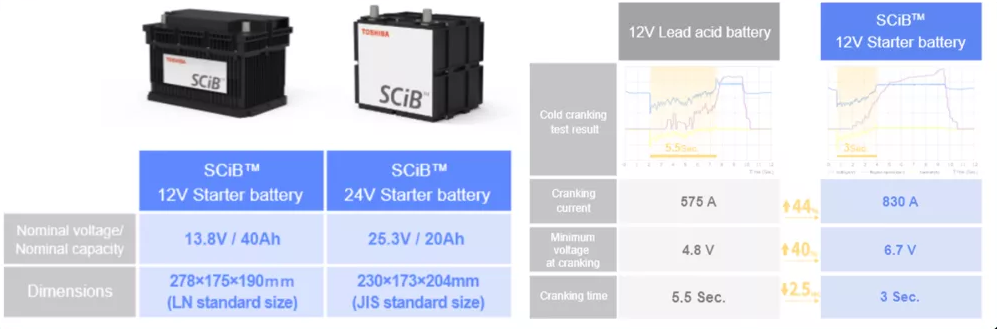

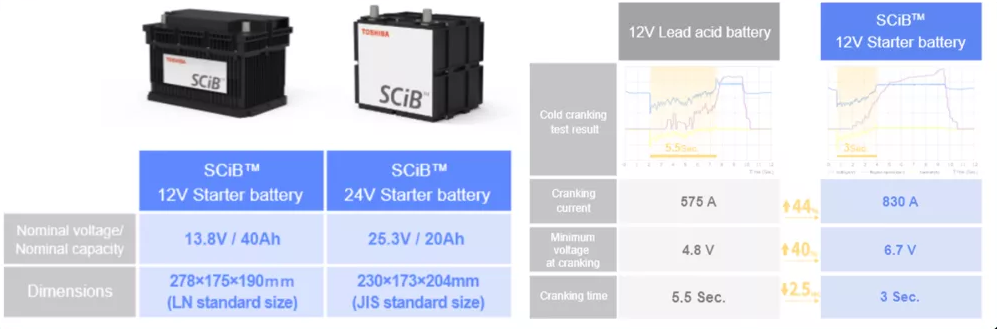

Honestly, this is not something difficult to predict, because the 12V/24V/36V/48V applications of lead-acid batteries have been penetrated extremely quickly by lithium batteries. These lithium battery products have exactly the same appearance and size as lead-acid batteries, but the performance is far superior to lead-acid batteries, the specific differences can be found in the table produced by SES Power.

Items | LiFePO4 | Lead Acid | Remark |

Specification | 12.8V 100Ah, 1280Wh | 12V 100Ah, 1200Wh |

|

Weight | 11kg (116wh/kg) | 32kg (40wh/kg) | ⅓ : 1 |

Cycle Life | 5000 cycles, @30% DOD | 1000 cycles, @30% DOD | 8 : 1 |

4000 cycles, @50% DOD | 500 cycles, @50% DOD |

3000 cycles, @100% DOD | 200cycles@, 100% DOD |

Discharge Characteristics @rating | 100% of rated capacity, @C10 | 100% of rated capacity, @C10 | @20℃ |

100% of rated capacity, @C5 | 90% of rated capacity, @C5 |

100% of rated capacity, @C2 | 70% of rated capacity, @C2 |

100% of rated capacity, @C1 | 50% of rated capacity, @C1 |

Discharge Characteristics @temp. | 100% of rated capacity, @C10, 20℃ | 100% of rated capacity, @C10, 20℃ | @60%±25%RH |

85% of rated capacity, @C10, -20℃ | 65% of rated capacity, @C10, -20℃ |

100% of rated capacity, @C1, 20℃ | 40% of rated capacity, @C1, 20℃ |

80% of rated capacity, @C1, -20℃ | N/A, @C1, -20℃ |

Self-discharge Characteristics @temp. | 0.8%/month, @10℃ | 1.5%/month, @10℃ | @60%±25%RH |

1.5%/month, @20℃ | 3.5%/month, @20℃ |

2.0%/month, @30℃ | 4.5%/month, @30℃ |

2.5%/month, @45℃ | 12.5%/month, @45℃ |

But we were focusing more on the energy storage market, and less attention was paid to lead-acid battery replacement in the starting category, limited by market acceptance, performance differences, and price disparity. From 2019, lithium replacement lead-acid batteries, in the energy storage market has been significantly heated up, and the lithium replacement lead-acid for starter class also showed a booming trend, SES Power also started to launch 12V/24V replacement lead-acid battery products for starter at that time.

It is important to acknowledge that the market is determined by consumers, but lead and pushed by the big companies.

With the Model S Plaid, Tesla's small-scale replacement experiments have proven that the solution works, and the next step has been to gradually begin preparations for a larger-scale replacement in the Model 3 and Model Y. In fact, this is constantly pushing other brands in the market, such as BMW, Daimler, Porsche, Audi, these luxury brands have also accelerated the pace of lithium batteries to replace lead-acid batteries.

In other words, in this field, the traditional dominance of lead-acid batteries may be gradually broken in the next few years.

Part 1 Tesla is importing 12V lithium battery on a large scale

From the overall perspective, Tesla is seriously thinking about replacing all lead-acid batteries.

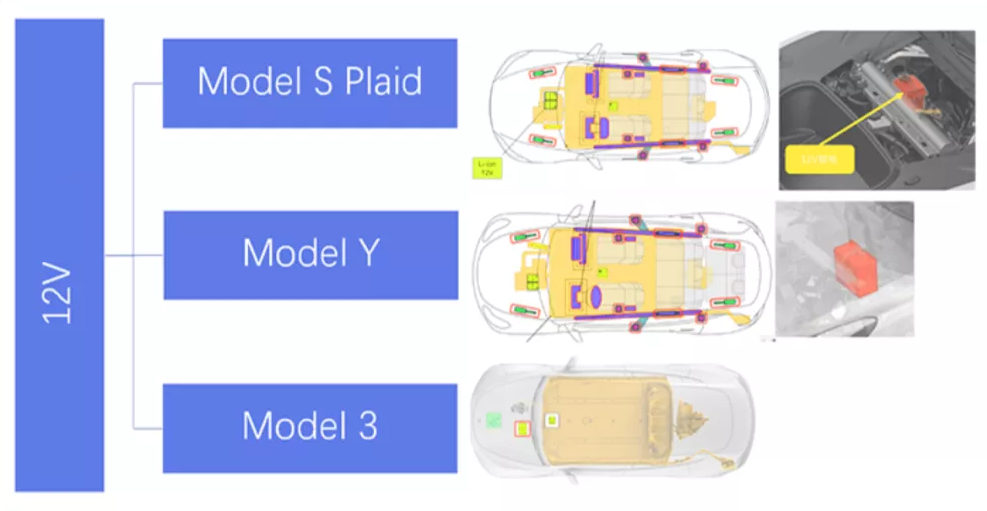

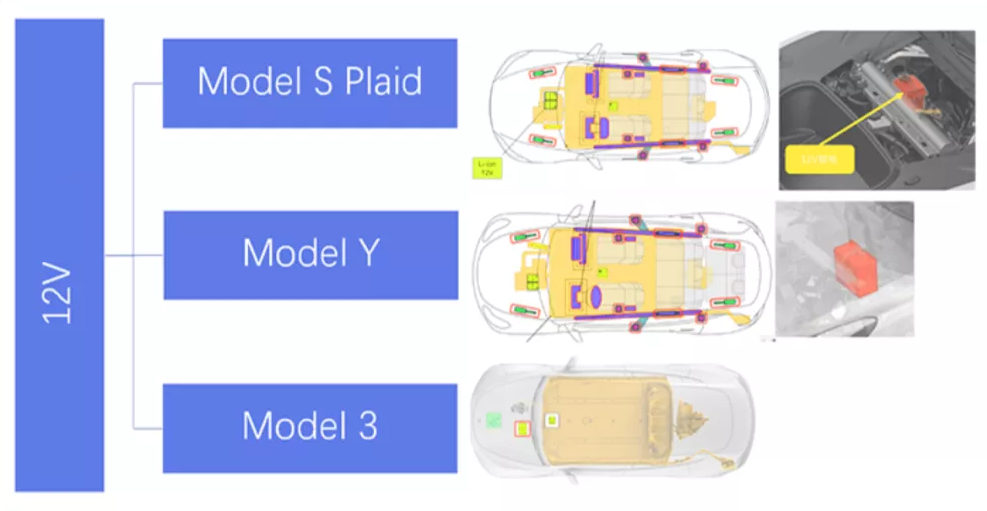

The previous generation Model S/Model X and Model 3 and Model Y used 12V & 33Ah lead-acid AGM batteries (weight is 12kg), and the first replacement attempt was practiced on the Model S Plaid. When the real car test is OK and the supplier is OK, the whole replacement process will be very fast. As shown in Figure 1 below, the gradual replacement has already started on the US-made Model Y.

▲Figure 1. New battery on Tesla Model Y

The new battery will be replaced on all platforms in a holistic manner after the completion of the small batch experiment, as shown in Tesla's product chart.

▲Figure 2. The replacement of Tesla's series

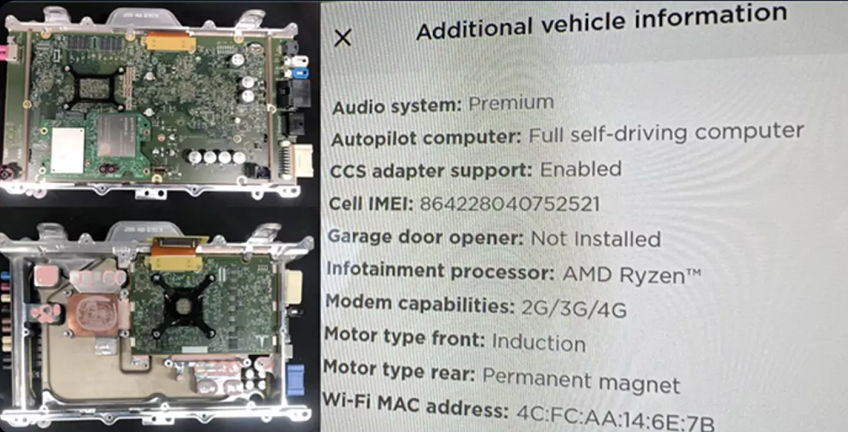

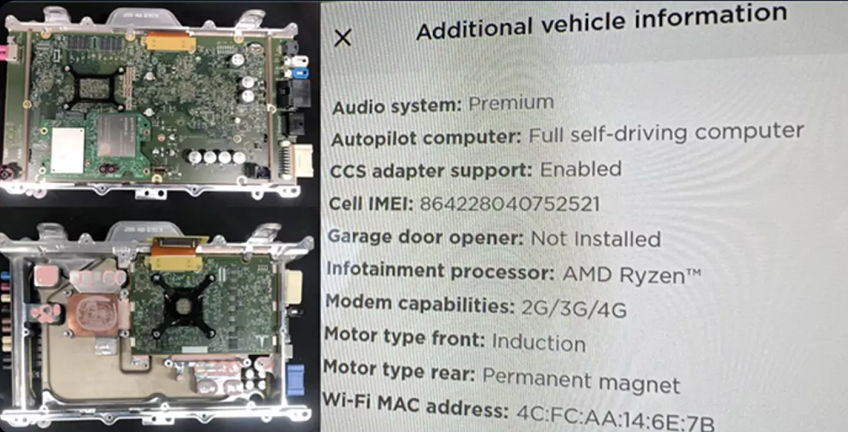

The new generation of AMD Ryzen chips will be rolled out massively and substantially.

▲Figure 3. The 3rd generation of platform-based entertainment control system that Tesla is going to introduce

In the previous article, SES Power has demonstrated the advantages of storage type lithium iron phosphate batteries to replace lead-acid batteries. For the starter class replacement, in Tesla's view, the main differences between 12V LiPo and lead-acid from a product revenue perspective are still in.

● Lifespan

Lead-acid batteries are used for about 2-4 years, while this 12V lithium may have to accompany the entire vehicle's lifetime (10 years) or so to consider.

●Weight.

In terms of weight, it has been reduced from 12kg to 1.8kg.

●Volume and Capacity.

In terms of overall, the nominal 12V Li-ion battery is very small with only 99 Wh of energy and the nominal 14.8V Li-ion battery has a capacity of 102 Wh of energy (including 4 square-case NMC 3.7V cells).

● Communications Protocol and Management.

These Li-ion batteries contain BMS and external LIN bus connection inside, which can detect and control the battery in time and accurately. This is something that lead-acid batteries cannot do at all.

Tesla has been leading the trend of electric vehicles, starting lithium batteries, this replacement action obviously has a deep meaning of demonstration, which will certainly accelerate the entire industry of lithium batteries to replace lead-acid batteries, and will spread to traditional fuel cars, 48V/HEV on, not only affect pure electric vehicles.

The core issue in SES Power's view is that the life of this design is considered to be 8-10 years, and the biggest concern is not the price difference between the two, but that this will break the after-sales service product pattern of 12V batteries. Don't get it? Simply put, the consumer is benefited, but the overall aftermarket pattern is broken, which will lead to the traditional benefit chain is hit hard.

That's why SES Power has given priority to promoting lithium batteries as a replacement for lead-acid batteries in the energy storage industry, rather than in the traditional automotive industry, more because of concerns about the aftermarket siege, because lead-acid batteries in the starter category account for more than half of all lead-acid battery output! -- As early as 2012 A123 had to Daimler to provide lithium replacement lead-acid batteries, but because the aftermarket and dealer system is too strong… This is more scary for SES Power than facing a Tyrannosaurus Rex. :)

After a few years of brewing, in the field of traditional cars, the first to start gradually batch use of 12V lithium batteries are BMW, Audi and Mercedes-Benz several luxury car companies; the main models include BMW M3/M4 Mercedes AMG, GLC, S-Class SLS AMG Coupe/ SLS S63 AMG S65 AMG Coupe/ Porsche sports cars. Soon after, BMW included LG Chem in the supplier system, and the main use is in replacing lead-acid batteries.

We estimate that in this regard, regardless of whether we take the ternary lithium battery route or the lithium iron phosphate route, the key to getting through this road is: standardization and low-cost cells.

▲Figure 4. In the original traditional architecture of 12V lithium battery, the starting current is still required to be high.

Part 2 The situation in China

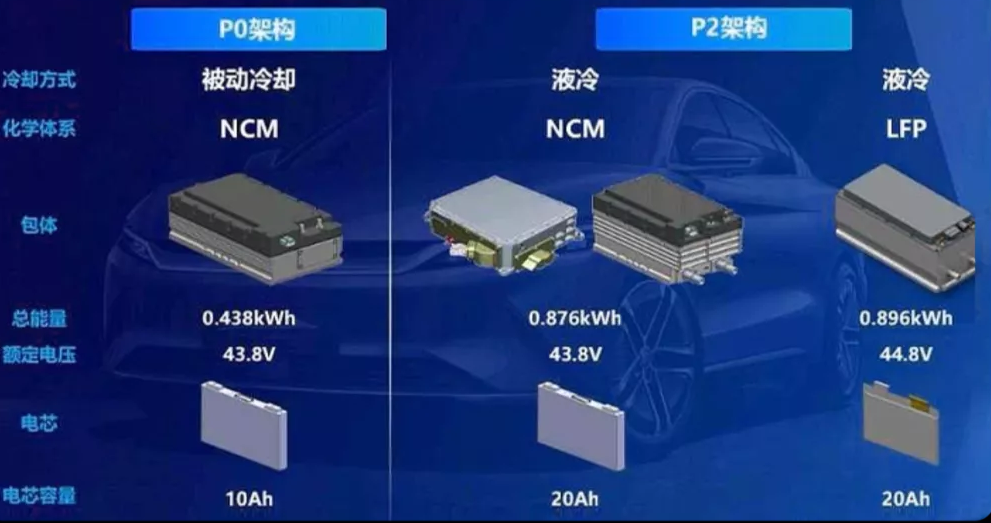

China has abandoned the traditional fuel car route and is fully invested in this technology route of electric vehicles. Interestingly, BYD is promoting the 12V battery "lithium for lead-acid" program on its DM-i hybrid full range of models, as shown in the following figure.

▲Figure 5. 12V lithium battery of BYD DM-i

SES Power's understanding is that it was applied in the early Qin first generation, the effect is not too good, and it has actually been improving in these years, and the path to the third generation in 2021 is basically unchanged.

▲Figure 6. BYD's iterative path

From the technical specifications: this nominal 13Ah battery is gradually reduced compared to the capacity of previous products, but the weight is done already similar to Tesla's design (2.2kg PK 1.8kg). Although the entire battery capacity than 6.9Ah is also quite large, this weight difference is not large, basically by the form and material of the Pack. The company's main goal is to provide the best possible solution to the problem.

▲Figure 7. BYD do 12V lithium with lithium iron phosphate, HEV and 48V with ternary and lithium iron compatible

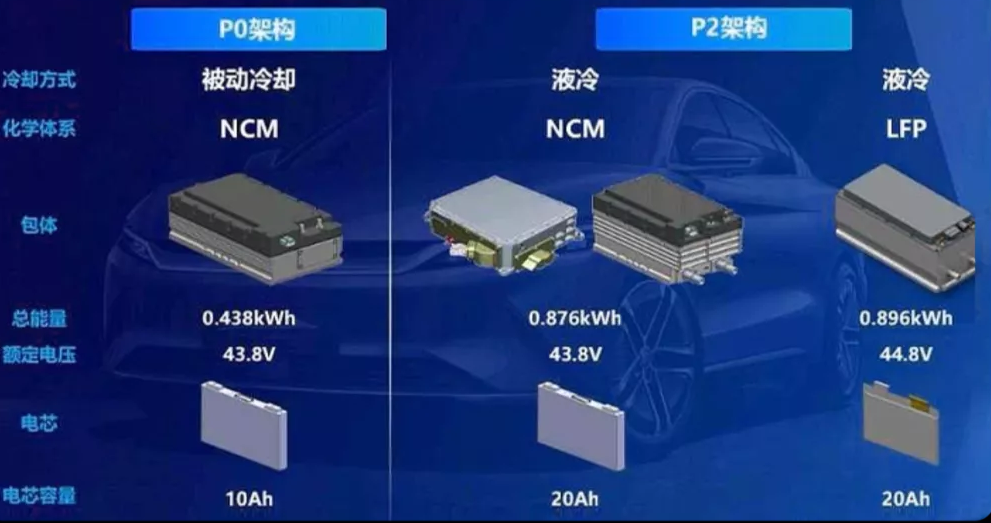

The following chart is the technical route of BYD's 48V battery, mainly divided into the ternary and LFP route, the latter is a soft pack design, and the cost is not estimated to be low in the short term.

▲Figure 8. BYD's 48V battery route

Here are the routes of two different systems of HEVs, and it is estimated that the latter has a little more room to move down the price system.

▲Figure 9. BYD's HEV battery route

Summary by SES Power: From the big logic, lead-acid batteries are currently being beaten badly by lithium batteries in all aspects, as the latter's technology has become increasingly mature and the cost is decreasing year by year. At present, the main factor that can restrict its replacement speed is the supply and price of raw materials for lithium batteries, which is really the biggest shortcoming that there is no way to enhance the supply in the short term.