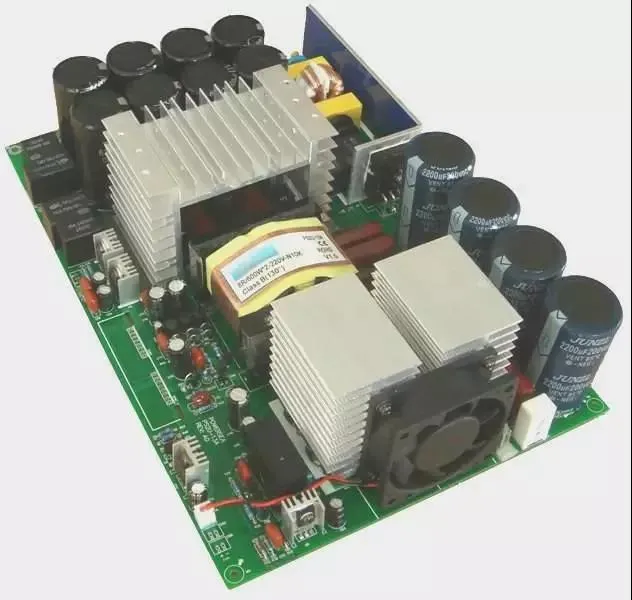

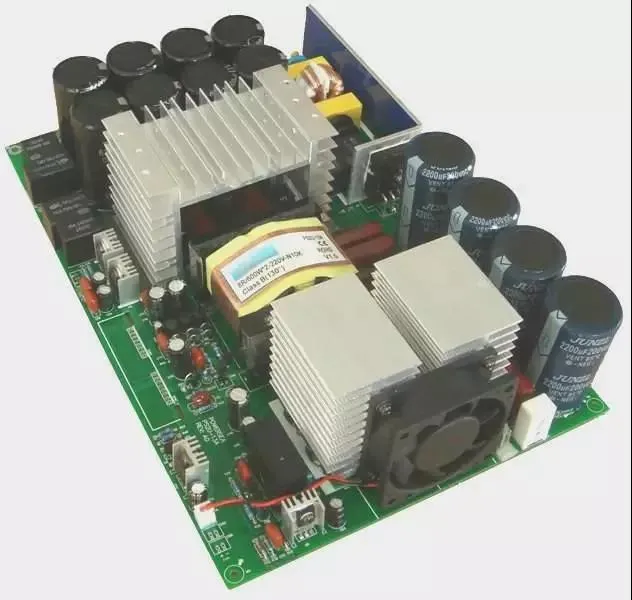

PCB thermal dissipation is vital, 10 principles must be followed

For electronic equipment, a certain amount of heat is generated during

operation, so that the internal temperature of the equipment rises rapidly. If

the heat is not dissipated in time, the equipment will continue to heat up, and

the component will fail due to overheating. The reliability of the electronic

equipment Performance will decrease. Therefore, it is very important to conduct

a good thermal dissipation treatment on the circuit board. The thermal

dissipation of the PCB circuit board is a very important link, so what is the

thermal dissipation technique of the PCB circuit board, let's discuss it

together below.

1. Thermal dissipation through the PCB board itself

PCB board has excellent electrical properties and processing properties,

but poor thermal dissipation. It is almost impossible to expect heat to be

conducted by the resin of the PCB itself, but to dissipate heat from the surface

of the component to the surrounding air.

2. Using radiator, heat conduction plate

This is the most common way. A radiator or heat pipe can be added to the

high heat components. When the temperature cannot be lowered, a radiator with a

fan can be used to enhance the thermal dissipation effect. Usually, a soft

thermal phase change thermal pad is added on the surface of the component to

improve the thermal dissipation effect.

3. Free convection air cooling

If this kind of thermal dissipation method is adopted, it’s better to

arrange the integrated circuits (or other components) in a vertical manner or in

a horizontal manner.

4. Adopt reasonable wiring design to realize thermal dissipation

This method relies heavily on the design ability of the engineer. The resin

in the plate has poor thermal conductivity, and the copper foil lines and holes

are good conductors of thermal. Therefore, increasing the copper foil area and

increasing the thermally conductive holes are the main means of thermal

dissipation.

5. Layout the thermal source according to the air flow direction

The components on the same printed board should be arranged as far as

possible according to their calorific value and degree of thermal dissipation.

The components with small calorific value or poor heat resistance should be

placed on the uppermost flow (entry) of the cooling airflow, and those

components with calorific value or good heat resistance should be placed at the

most downstream of the cooling airflow.

6. Considering the impact of high-power components on the surroundings

In the horizontal direction, the high-power components are arranged as

close to the edge of the printed board as possible; in the vertical direction,

the high-power components are arranged as close as possible to the top of the

printed board, which can reduce the influence of these components on the

temperature of other components during operation.

7. Study the air flow path

The thermal dissipation of the printed board in the equipment mainly relies

on air flow, and the air flow always tends to flow in places with low

resistance. Therefore, when configuring components on the printed circuit board,

avoid leaving a large airspace in a certain area. The configuration of multiple

printed circuit boards in the whole machine should also pay attention to the

same problem.

8. Appropriate placement of temperature-sensitive components

This type of component is best placed in the lowest temperature area (such

as the bottom of the component). Never place it directly above the heating

component. It is best to stagger multiple components on the horizontal

plane.

9. The component layout with the largest heat generation

The components that generate the most thermal are arranged near the best

position for thermal dissipation. Do not place high-heating components on the

corners and peripheral edges of the printed board, unless a heat sink is

arranged near it.

10. Avoid gathering of hot spots

Distribute the power evenly on the PCB board as much as possible to keep

the PCB surface temperature performance uniform and consistent.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

substitute for lead-acid batteries, and are the first choice for grid-connected

peak shaving, off-grid energy storage, photovoltaic energy storage, UPS, data

center and other industries.