Will lithium-ion batteries be designed and manufactured to approach their theoretical performance limits in the near future? As a specialist in lithium-ion battery solutions, SES Power has been paying close attention to this topic, and a recent report offers five ways to improve.

(Alex Holland)

Technology business consulting firm IDTechEx has published a newspaper article dubbed "2022-2032 Advanced Li-ion Batteries and Beyond Lithium Batteries: Technologies, Players, Trends, Markets," written by energy storage technology experts Alex Holland and Xiaoxi He.

According to the co-authors, five key points are summarized in the article: "Current iterations of lithium-ion batteries are based on graphite anodes, liquid electrolytes, and cathode materials such as nickel-cobalt-manganese and lithium iron phosphate, which are generally considered to have reached the limits of battery performance. However, there are still several ways to further improve performance and cost, from cell materials to cell design."

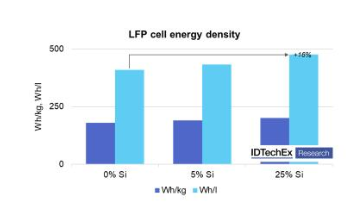

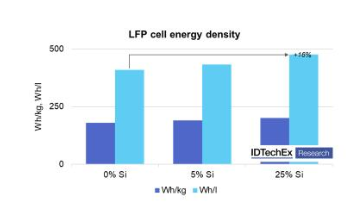

A: The Shift from Graphite to Silicon

Silicon anodes are expected to significantly improve energy density and performance and can be an exciting alternative to graphite. Although the material silicon is used in very small quantities in anodes, it is difficult to move beyond its use as an additive because of its inherent bulk expansion and resulting stability and cycle life issues.

(How silicon materials have increased energy density)

However, silicon anode technology has steadily improved over the past 10 to 15 years, allowing batteries to use more silicon in the anode.

Developments in 2022 highlight the interest in the technology, including Nexeon raising $200 million in funding and licensing materials from SKC, Amprius' decision to go public, Group14 Technologies' $400 million funding round, and POSCO Holdings' acquisition of Tera Technos. in addition, Amprius delivered 450 Wh/kg of commercial batteries for satellites, however the September 2021 release of the Whoop 4.0 fitness wearable device utilizes Sila Nano's silicon anode technology.

In conjunction with these developments, the silicon anode market is becoming increasingly likely to be adopted in a variety of applications and the silicon anode market is becoming more mature. For example, IDTechEx predicts significant growth in the use of silicon anode materials, although graphite is expected to remain dominant through 2030.

B: New approaches to cathode synthesis

Future lithium-ion batteries may use similar cathode materials that are commercially available today. Improving cathode materials is usually incremental.

Instead, the biggest shifts in cathode technology and innovation may stem from the way they are synthesized. Current synthesis techniques require high temperatures over relatively long time periods (days) and also require the use of large amounts of reagents and water, resulting in high manufacturing costs and environmental impacts. two companies, Nano One Materials and 6K Energy, aim to commercialize new methods of synthesizing cathode materials.

Nano One Materials utilizes a solution-based 'one-pot' method to produce coated cathode materials. The company has partnered with cathode manufacturer Pulead and signed a development agreement with BASF in early 2022.

6K Energy uses microwave plasma reactors to produce its cathode materials, although they are also able to synthesize silicon anode and solid electrolyte materials. 6K Inc closed a $102 million deal in May 2022 in a Series D financing round and has development agreements with lithium producer Albemarle and cathode startup Our Next Energy.

Both Nano One Materials and 6K Energy are expected to streamline production processes to increase throughput, yield, lower manufacturing costs and reduce environmental impact.

C: Solid State Electrolytes and Novel Electrolyte Formulations

While solid-state electrolytes have attracted a great deal of attention to electrolyte technology, liquid electrolyte systems can be continually improved using new additives and electrolyte formulations. For example, New Dominion Enterprises is developing electrolyte additives and solvents based on phosphonitrile and phosphorus-nitrogen compounds to improve safety and performance.

(Polymer Electrolytes)

Specifically, its electrolyte additive materials can provide thermal stability and improve SEI formation. In the long term, the company aims to completely replace conventionally used organic solvents with their electrolyte systems and has the potential to significantly improve safety.

However, the most important battery technology for many electric vehicle manufacturers remains the solid-state battery, and they can significantly improve safety by replacing the flammable liquid electrolyte currently in use with a solid-state electrolyte. In addition, solid-state electrolytes offer the potential to use lithium metal anodes with energy that may exceed 1,000 Wh/l.

The solid-state battery market is expected to grow to over $8 billion in 2031, with liquid electrolytes remaining a significant part of the market. The challenges of solid state electrolyte systems in terms of stability, cycle life, manufacturability and even in terms of safety mean that competition between different electrolyte systems continues.

D: New battery pack technologies will save space

For electric vehicles in particular, battery pack design offers another key way to enhance performance. Many automotive companies have adopted cell-to-battery pack designs to eliminate materials associated with module housings, optimize pack efficiency, and ultimately help increase energy density and improve battery-vehicle integration.

BYD touts an increase in capacity utilization from 40% to 60%, and battery manufacturer CATL claims that its latest cell-to-pack design can achieve 72% capacity utilization. early in 2022, CATL announced that LiFePO4 packs can reach 160Wh/kg and 290Wh/l to compete with NiCoMn packs.

Maximizing energy density helps mitigate the major drawbacks of inexpensive lithium iron phosphate batteries, providing a new pathway to inexpensive and long-range batteries. These types of battery designs do have the disadvantage of reduced availability, which can limit their use in commercial vehicles.

E: More advanced battery management systems

Improvements in battery management systems (BMS) can provide a pathway to improve multiple aspects of battery performance without the challenges associated with materials development.

For example, Qnovo highlights how its battery management system software and analytics can help simultaneously improve safety, cycle life and charge time, as well as increase the available battery capacity. The company achieves this by combining battery usage data with cell impedance measurements that inform the physical model of the lithium-ion battery, which in turn can be used to optimize operation and charging protocols. Another use case for its battery management system solution may come from battery failure detection, which has been valuable in recently recalled electric vehicles.

In addition to electric vehicles, improved battery management systems are also of high value for other end uses such as smartphones and power tools. OnePlus touts the 10T phone's ability to charge from 1% to 100% in just 19 minutes, in part due to smarter charging algorithms and more efficient thermal management. In addition to this fast-charging capability, OnePlus also touts a cycle life of 1,600 cycles that exceeds that touted by LCOs and consumer electronics batteries.

While battery development often includes trade-offs between key performance characteristics such as energy density, cycle life, fast charging, and safety, improvements in battery management systems may bring improvements to all of these characteristics.

Ultimately, there are a number of ways to improve battery performance and cost, including others not discussed in this article. While some developments may only provide incremental benefits, the combination will allow lithium-ion battery performance to continue to move steadily forward.

As a manufacturer with nearly two decades of experience in the lithium battery industry, SES Power has focused early on the product needs of lithium battery energy storage systems, for which we have introduced corresponding products for different application scenarios to achieve the best price/performance ratio, such as lead-acid replacement products with balanced performance of square aluminum-cased lithium iron phosphate batteries (12V100Ah, 12V200Ah, 24V100Ah, etc.), high-current (2000A) startup lithium battery, UPS high-voltage lithium battery system (up to 860V), 3Kw~20Kw off-grid, grid-connected, islanded lithium battery energy storage system, wall-mounted home energy storage system 48V100Ah, 48V200Ah, stacked energy storage system (single 51.2V100Ah, supporting up to 15 stacking), etc.

If you have any questions about lithium batteries, you are welcome to contact us.