How are the cells connected to form a lithium-ion battery pack, is it very easy to do with screws or simple welding? In fact, the connection technology between the cells is very important and technically advanced.

The lithium-ion battery system has gradually become the most important power source for electric vehicles and energy storage systems because of its high energy ratio, high power ratio, long cycle life, safety and reliability advantages.

It is not uncommon for lithium-ion battery systems to have safety failures, and there are many factors affecting them, such as: excessive charging and discharging, short circuit, collision, high temperature, loose connection, etc.. Among them, there are more safety accidents caused by loose connection between cells, and there are difficulties such as large uncertainty and difficult diagnosis of loose connection, so it is important to study the connection technology of lithium-ion battery system for the improvement of safety performance, process optimization and optimization of production and manufacturing engineering of lithium-ion battery system.

As a manufacturer with nearly 20 years of experience in the lithium-ion battery system industry, SES Power believes that many people do not pay enough attention to the connection technology between the cells, they think it is a "small thing", in fact, according to our experience, if the lithium battery system is relatively small, low power, application scenario is friendly, indeed this aspect is not a key factor. But if it is a medium to large Li-ion battery system, such as golf cart Li-ion battery, energy storage system, power system, etc., then the importance of the connection technology between the cells will increase exponentially.

SES Power insists on safety as the first starting point, so we have a deep knowledge of the connection technology between the cells. Let our senior engineers analyze various aspects about the connection technology of Li-ion battery for you in detail.

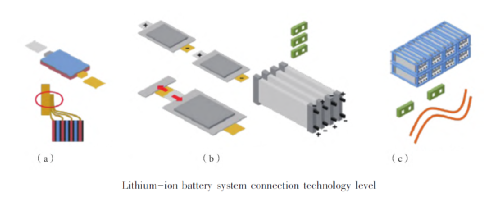

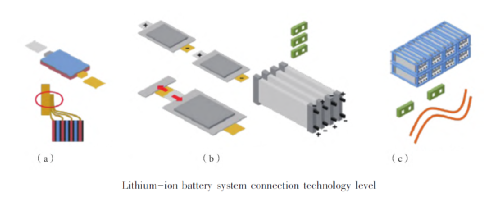

A: What are the connection levels of Li-ion battery system?

In lithium-ion battery system, from the process point of view, there are three main levels of connection between: electrodes-to-cell (Electrodes-to-Tab) and case sealing (CaseSealing) at the cell level, cell-to-cell (Cell -to-Cell), and Module-to-Module at the pack level.

Since the lithium-ion battery system consists of numerous cell-to-cell and module-to-module components, there are many connection technologies involved. Common connection techniques include: ultrasonic welding, resistance spot welding, laser welding, pulsed TIG welding, mechanical connection, etc.

B: Ultrasonic welding

Ultrasonic welding is a solid-state welding process in which the workpiece does not need to be melted. It is based on the principle of using the mechanical vibration energy of high-frequency ultrasound (usually above 20 kHz) to tighten and frictionally fuse the workpiece together.

Ultrasonic welding can be widely used for joining many forms of metal foils, for welding between workpieces of the same material, and for welding between workpieces of different materials with different melting points. In addition, ultrasonic welding is also widely used in the connection of battery systems due to its high efficiency and speed, the ability to operate at low temperatures, and its applicability to the environment. The main factors limiting the application of ultrasonic welding in lithium-ion electronic systems are the low welding thickness (<3 mm) and the inability to achieve welding of workpieces made of high-strength materials.

The parameters of ultrasonic welding have a large impact on the welding performance of lithium-ion battery systems, mainly in terms of weld quality, mechanical properties, electrical properties, and thermal properties.

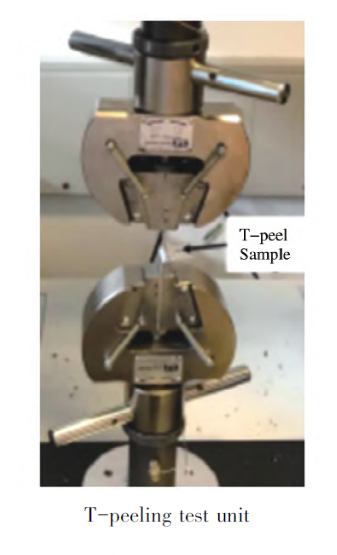

C: Resistance spot welding

Resistance spot welding is a welding process in which the workpiece is pressed through the electrode and current is induced, and then the workpiece is fused by relying on the local heat generated by the resistance of the metal workpiece interface.

Since resistance spot welding has the advantages of relatively mature process, easy control, low cost and high efficiency, it is most widely used in the traditional automotive manufacturing industry. Similarly, resistance spot welding has a wide range of applications in the joining of lithium-ion batteries, especially in the manufacturing of small-sized cylindrical battery cells.

The process parameters that affect resistance spot welding are current, pressure, and pressurization time, the most important of which are peak current and peak current time. This is due to the fact that the current is too low or the peak current time is too short for the workpiece interface to generate the heat required for localized melting, thus preventing the formation of a continuous fusion. But the peak current and peak current time should not be too high either, because if the workpiece is exposed to the peak current for a long time, excessive local heat may be generated, thus vaporizing the material. Therefore, in order to manufacture excellent quality lithium-ion battery systems, suitable resistance spot welding process parameters need to be optimized.

Resistance spot welding has a very wide range of applications for Li-ion battery connections, especially for cylindrical Li-ion batteries, such as 18650 Li-ion batteries, 21700 Li-ion batteries, 32650 Li-ion batteries, etc. It also faces many challenges. There are three main points: (1) lithium-ion batteries commonly used in high conductivity materials (copper and aluminum), not suitable for resistance spot welding; (2) the process is to make the workpiece melt to achieve the purpose of welding, different materials due to their different melting points, it is difficult to be welded; (3) difficult to apply to the welding of multi-layer workpiece, as well as difficult to produce a larger nucleus.

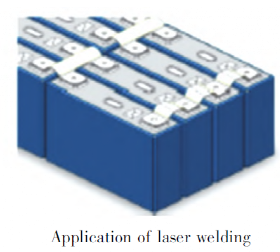

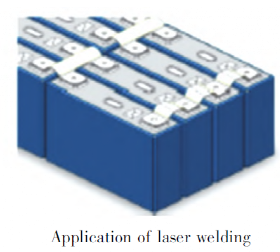

D: Laser welding

Laser welding is a non-contact welding process in which a laser beam generates heat to heat the workpiece and simultaneously join multiple layers of metal together, usually within a few milliseconds.

As a non-contact welding process, laser welding has corresponding advantages for the joining of lithium-ion battery systems. Because laser welding has the smallest heat affected zone of any welding process and can be used to join multiple layers of sheets, laser welding is considered the most efficient welding process for lithium-ion battery systems.

There are many factors that affect laser welding, mainly oscillation-related oscillation frequency and amplitude, laser-related power frequency and pulse duration, and device-related movement rate and focus range.

At the same time, laser welding requires high accuracy of workpiece assembly position and requires welding materials to meet properties such as high reflectivity and high thermal conductivity, so this makes the implementation of laser welding in lithium-ion battery connection applications more difficult.

SES Power continued to explore and eventually concluded the corresponding corresponding experience: when welding the lugs to the terminals, the lugs need to be thinner than the thickness of the battery case terminals, while the processing parameters need to be strictly controlled so as to provide sufficient welding energy without penetrating the battery case. Also, since the melt pool of laser welding is small and the gap tolerance is small, better results can be obtained by pressing the lugs onto the battery when lug welding is performed.

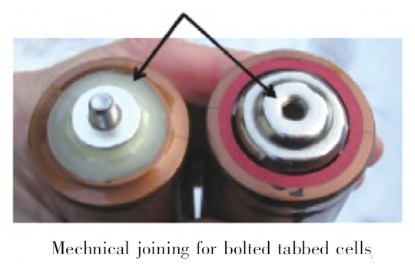

E: Mechanical connection

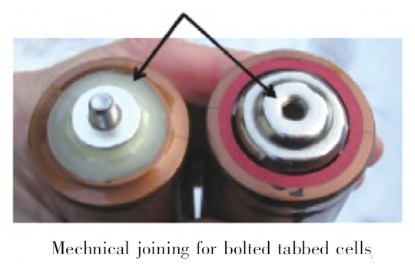

A variety of mechanical methods can be used to connect lithium-ion battery systems, such as nuts, bolts, screws, or snaps.

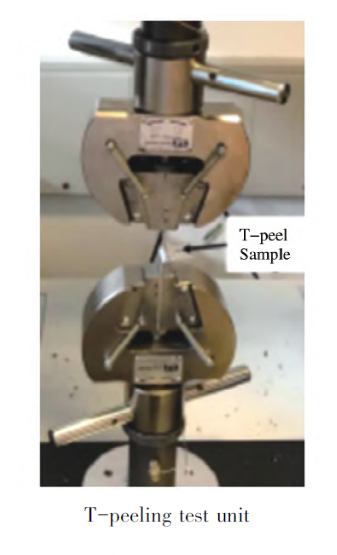

Mechanical connections have the advantage of high strength, easy disassembly for maintenance, and usually operate without heat. However, different mechanical connection processes and their characteristics need to be noted in the selection process. We studied different bolted connections such as nuts and bolts, flow-drilled screws and thread-formed screws by different power outputs and tested their resistance and heat generation.

The results show that the resistance after these mechanical connections increases with time! And in addition to the change in contact resistance, when the current, heat is large enough, prolonged use will lead to oxidation of the connection point, increased resistance, loosening and other phenomena, and this phenomenon is a positive feedback, once the situation will be aggravated in a shorter period of time behind the poor performance.

Even if we use the so-called best screw fastening glue or thermal conductive materials, they can not prevent this from happening.

F: Summary

With the development of electric vehicles and energy storage systems, the connection technology of lithium-ion battery systems has also made great progress. At the same time, the production of high-quality lithium-ion battery systems has gradually become the most critical issue in the field of battery production and manufacturing.

In order to meet the demand for high-quality lithium-ion battery systems, it is necessary to conduct more in-depth technical research on the connection technology. In addition to CT inspection and visual inspection of the connection condition, CAE analysis can also be introduced to simulate the connection process, optimize the process parameters, reduce the number of tests, and improve the production efficiency and connection performance results.

SES Power believes that as technical research continues, the process elements of various connection technologies will become clearer, the manufacturing process control will become more and more refined, and the quality of lithium-ion battery systems will be more assured.

Many of our products are lithium battery systems with higher energy and output power, such as lead-acid replacement products with high-quality square aluminum-cased lithium iron phosphate batteries (12V100Ah, 12V200Ah, 24V100Ah, etc.), high-current (2000A) starter lithium batteries, UPS high-voltage lithium battery systems (up to 860V), 3Kw~20Kw off-grid, grid-tied, and Islanded lithium battery energy storage system, wall-mounted form of home energy storage system 48V100Ah, 48V200Ah, stacked energy storage system (single 51.2V100Ah, up to support 15 stacks), etc. So, we always pay attention to the development of the connection technology between this battery cell.

If you have any questions about Li-ion battery, you are welcome to contact us.