What are the energy storage technologies in the smart grid?

Energy storage technology has a wide range of applications in many fields,

including power systems. In recent years, the reorganization of the power

industry worldwide has brought new development opportunities to a variety of

energy storage technologies. The use of these technologies can be more

effective. This effect is particularly obvious in realizing the energy

management of the power system, especially in the field of renewable energy and

distributed power generation. In traditional power generation and transmission

and distribution networks, these new technologies can also be applied. The

following briefly introduces the basic principles and development status of

various energy storage technologies.

1Pumped water storage Pumped storage power station must be equipped with

two reservoirs upstream and downstream. During the low load period, the pumped

energy storage equipment works in the state of the motor, pumping the water from

the downstream reservoir to the upstream reservoir for storage. At peak load

times, the pumped water energy storage equipment works as a generator and uses

the water stored in the upstream reservoir to generate electricity. Some

high-dam hydropower stations have water storage capacity and can be used as

pumped storage power stations for power dispatch. It is also technically

feasible to use mines or other caves to achieve underground pumped energy

storage. The ocean can sometimes be used as a downstream reservoir. In 1999,

Japan built the first pumped-storage power station using seawater. Pumped

water storage was first applied in Italy and Switzerland in the 1890s. In 1933,

reversible units (including pump turbines and electric motors and generators)

appeared, and now there are adjustable speed units to improve energy efficiency.

The pumped storage power station can be built with any capacity, the release

time of the stored energy can be from a few hours to a few days, and its

efficiency is between 70% and 85%.

Pumped water storage is the most widely used energy storage technology in

power systems. Its main application areas include energy management, frequency

control, and provision of system reserve capacity. At present, there are more

than 90GW of pumped energy storage units in operation worldwide, accounting for

about 3% of the world's total installed capacity. An important constraint

restricting the wider application of pumped storage power stations is the long

construction period and large project investment.

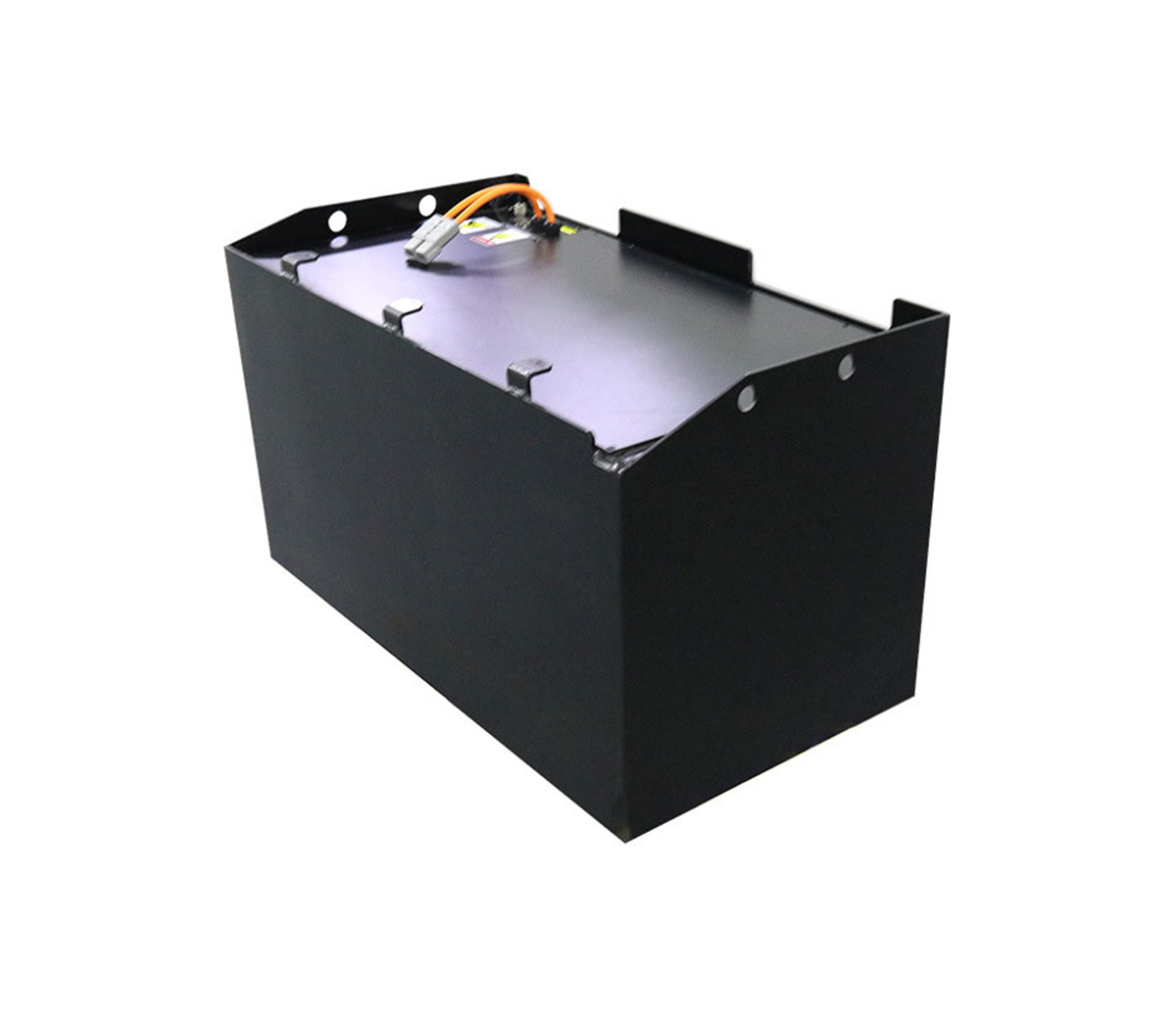

2 Advanced battery energy storage

It is estimated that the global annual market demand for storage batteries

is approximately US$15 billion. In terms of industrial storage batteries, such

as UPS, power quality adjustment, backup batteries, etc., the total market can

reach US$5 billion. In the United States, Europe, and Asia, companies that

produce high-performance storage batteries for power systems are being

established. In the past 12 to 18 months, a battery production line with a

production capacity of 300MW per year has been put into operation.

Lead-acid battery is the oldest and most mature battery technology. It is a

low-cost universal energy storage technology that can be used for power quality

adjustment and UPS. However, due to the short life of this battery, its

application in the field of energy management is limited. ZnBr battery was

successfully developed by Exxon in the early 1970s. After years of research and

development, many ZnBr battery energy storage systems with a capacity of several

kilowatt-hours have been built and tested, with a net efficiency of 75%. In the

early 1980s, the University of New South Wales in Australia took the lead in

developing VRB (Vanadium Redox Flow Battery) batteries. Currently, a 500kW/5MW?h

VRB energy storage system has been installed in Japan, with a net efficiency of

85%.

In recent years, various new types of storage batteries have been

successfully developed and applied in power systems. Regenesys Technologies in

the United Kingdom is using PSB (Polysulfide Broe Flow Battery) batteries to

build a 15MW/120MW?h energy storage power station with a net efficiency of about

75%. The NaS battery has a high energy storage efficiency (about 89%), and also

has the ability to output pulse power. The output pulse power can reach six

times the continuous rated power value within 30s. This feature allows the NaS

battery to be used at the same time It is used for the two purposes of power

quality adjustment and load peak-shaving and valley-filling adjustment, thereby

improving the economy of the overall equipment. In Japan, there are currently

more than 30 energy storage demonstration projects using NaS battery technology,

with a total energy storage capacity of more than 20MW, which can be used for 8h

daily load peak and valley adjustment.

Compared with other batteries, the main advantages of lithium-ion batteries

are high energy storage density (300~400kW?h/m3,130kW?h/t), high energy storage

efficiency (close to 100%) and long service life (every discharge It can be

recharged 3000 times when it does not exceed 80% of the energy storage). Due to

the above advantages, lithium-ion batteries have been developed rapidly.

However, although lithium batteries have accounted for 50% of the power supply

market for small mobile devices within a few years, there are still some

challenging tasks to be done to produce large-capacity lithium-ion batteries.

The main obstacle lies in its high cost. Mainly because it needs special

packaging and necessary internal overcharge protection circuit.

Among all the storage batteries, the Metal-air battery has the most compact

structure and is expected to become the lowest cost storage battery, which is a

kind of storage battery that is harmless to the environment. The main

disadvantage is that the charging of this battery is very difficult and the

efficiency is very low.

3 flywheel energy storage Most modern flywheel energy storage systems are

composed of a cylindrical rotating mass and a support mechanism composed of

magnetic suspension bearings. The purpose of using magnetic suspension bearings

is to eliminate friction loss and increase the life of the system. In order to

ensure a sufficiently high energy storage efficiency, the flywheel system should

be operated in a high vacuum environment to reduce wind resistance loss. The

flywheel is connected to a motor or a generator, and through some form of power

electronic device, the speed of the flywheel can be adjusted to realize the

power exchange between the energy storage device and the grid.

One of the outstanding advantages of flywheel energy storage is that it

requires almost no operation and maintenance, has a long equipment life (20

years or tens of thousands of deep charging and discharging energy processes)

and has no adverse effects on the environment. The flywheel has excellent cyclic

use and load tracking performance. It can be used in applications that are

between short-term energy storage applications and long-term energy storage

applications in terms of time and capacity.

In the realization of flywheel energy storage device, solid steel structure

flywheel or composite material flywheel can be used. The specific flywheel needs

to be compared with economy and technology, and the system cost, weight, size,

material performance and other indicators are compromised. Using high-density

steel materials, its edge linear velocity can reach 200-375m/s, while using

lighter weight and higher strength composite materials, its edge linear velocity

can reach 600-1000m/s. The actual output energy of the flywheel depends on its

speed range, it is impossible to output the rated power at a very low speed.

At present, high-power flywheel energy storage systems have been developed

and applied to aviation and UPS fields. Research institutions with BeaconPower

as the leading level are working on the optimized design of flywheel energy

storage so that it can be used for long-term energy storage services (up to

several hours) while reducing its commercial costs. At present, a 2kW/6kW?h

flywheel energy storage system has been used for power supply of communication

equipment. The use of a flywheel group (FlywheelFarmApproach) can realize an

energy storage device with an output power of megawatts and a duration of

several minutes or several hours.

4 Superconducting magnetic energy storage Although people discovered

superconductivity as early as 1911, it was not until the 1970s that it was first

proposed to apply superconducting magnetic energy storage as an energy storage

technology to power systems. Superconducting magnetic energy storage has quickly

attracted the attention of the power industry and the military due to its fast

electromagnetic response characteristics and high energy storage efficiency

(charge/discharge efficiency exceeding 95%). The application of SMES in the

power system includes: load balance, dynamic stability, transient stability,

voltage stability, frequency adjustment, power transmission capacity

improvement, and power quality improvement.

The SMES unit is composed of a superconducting coil placed in a low

temperature environment. The low temperature is provided by a cryogenic device

containing a liquid nitrogen or liquid helium container. The power

conversion/regulation system connects the SMES unit with the AC power system,

and can charge and discharge the energy storage coil according to the needs of

the power system. Two power conversion systems are usually used to connect

energy storage coils with AC power systems: one is a current source converter;

the other is a voltage source converter.

Compared with other energy storage technologies, SMES is still very

expensive. In addition to the cost of the superconductor itself, the cost of

maintaining low temperatures is also considerable. However, if the SMES coil is

combined with the existing flexible AC transmission device (FACTS), the cost of

the converter unit can be reduced, which generally accounts for the largest

share of the overall SMES cost. Existing research results indicate that for

transmission and distribution applications, micro (<0.1MW?h) and medium-sized

(0.1-100MW?h) SMES systems may be more economical. The use of high-temperature

superconductors can reduce the energy storage system's requirements for low

temperature and cooling conditions, thereby further reducing the cost of SMES.

At present, many SMES projects are underway or in the development stage around

the world.

5 super capacitor energy storage Capacitor is a kind of equipment widely

used in power system. Compared with conventional capacitors, supercapacitors

have a higher dielectric constant, a larger surface area, or a higher voltage

withstand capability. For example, ceramic supercapacitors have a fairly high

withstand voltage level (about 1kV) and dielectric strength, which makes them a

good candidate for future energy storage applications.

At present, super capacitors are mostly used in occasions with high peak

power and low capacity. Since it can work normally for more than ten years in a

fully charged floating state, the super capacitor can increase the power supply

level during voltage drops and transient disturbances. Supercapacitors are

simple to install, small in size, and can operate in a variety of environments

(hot, cold and humid), and can now provide commercial services for low-power

level applications.

6 compressed air energy storage

Compressed air energy storage is not a simple energy storage system like

battery energy storage. It is a gas turbine power plant for peak shaving. For

the same power output, it consumes 40% less gas than conventional gas turbines.

This is because conventional gas turbines need to consume about 2/3 of the input

fuel to compress air when generating electricity, while CAES can use the cheap

electric energy when the grid load is low to pre-compress air, and then release

the stored energy plus some gas as needed. To generate electricity. Compressed

air is often stored in suitable underground mines or caves under lava. It takes

about one and a half to two years to build such a cave through lava.

The first CAES put into commercial operation was a 290MW unit built in

Hundorf, Germany in 1978. The United States built the second commercial CAES in

McIntosh, Alabama in 1991, with a unit power of 110MW. The entire construction

took 30 months and cost US$65 million. This unit can be connected to the grid

within 14 minutes. The third commercial operation CAES, which is currently the

world's largest capacity CAES, is planned to be built in Norton, Ohio. The

entire power station has an installed capacity of 2,700MW and a total of 9

units. The compressed air is stored in an existing limestone that is 2200ft deep

underground. In the mine.