Earlier, Musk claimed that the energy density of the 21700 lithium battery

first used in Model 3 is close to 300 Wh/kg, which is almost the highest energy

density mass-produced lithium-ion battery in the world. Whether Tesla has set

another world record, we will wait and see.

Challenge unlimited chasing energy density is more risky

"Tesla claims that the energy density of battery cells is up to 300

watt-hours/kg. The higher the battery energy density, the higher the probability

of a combustion and explosion accident." Zhang Yu, Secretary-General of the

Power Battery Application Branch of the China Chemical and Physical Power

Industry Association Said that the core of the battery is the battery management

system, although Tesla has better solved the thermal runaway problem caused by

the increase in energy density through the battery system management technology,

and successfully avoided the short cycle life of the ternary lithium battery

through the car design. problem. However, if the energy density is to be further

improved, greater challenges will be presented to battery safety management.

The lithium-ion battery with the highest energy density claimed by Tesla is

not perfect in the eyes of industry experts.

Yang Yusheng, academician of the Chinese Academy of Engineering, emphasized

on many occasions that continuously increasing the specific energy of batteries

is a very dangerous way.

Previously, Wan Gang, Chairman of the China Association for Science and

Technology, publicly stated that from the market perspective, the driving range

is indeed an important sign of the technological progress of electric vehicles,

but its realization cannot be solved by simply increasing the amount of on-board

batteries.

"The greater the energy density of the battery, the greater the amount of

electricity stored per unit volume. The energy density and load capacity of the

battery determine the endurance of electric vehicles. In the past ten years, the

increase in battery energy density has mainly relied on the technological

progress of the battery material itself. And increase the proportion of active

substances in the battery." Yang Xulai, vice president of the Engineering

Research Institute of Guoxuan High-tech Power Energy Co., Ltd., said that by

increasing the size of the battery and reducing the weight of auxiliary

materials such as the casing, the energy density of the battery can also be

improved. Effect.

For the new energy industry that is responsible for the national curve

overtaking mission, the importance of power batteries is self-evident. Many

people in the industry admit that power batteries are the heart of new energy

vehicles, and how far a new energy vehicle can go depends mainly on power

batteries.

It is worth noting that according to the "Made in China 2025" power battery

development plan: By 2020, the energy density of domestic batteries will reach

300 Wh/kg. Experts believe that my country is actively promoting the development

of high specific energy batteries, but the relationship between battery safety

and specific energy is still worth studying.

Local companies can produce even if there are technical problems

Industry experts said that not only Tesla’s battery system control

capabilities, but also the vehicle design is not something that most Chinese car

companies can imitate and surpass in the short term. So, can local Chinese

companies create ternary lithium batteries that have the same battery life as

Tesla?

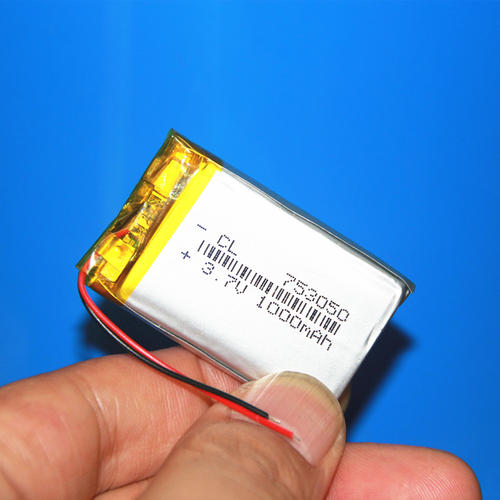

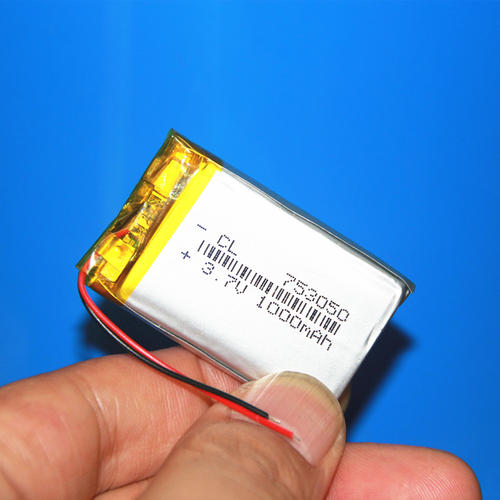

In the four main materials of the battery-positive electrode material,

negative electrode material, electrolyte and separator, the positive electrode

material not only accounts for 40% of the cost, but also directly determines the

energy density of the battery. According to the technical route of the cathode

material, power batteries can be mainly divided into three types: lithium iron

phosphate, ternary lithium (NCA/NCM) and lithium manganate batteries.

According to the composition of the cathode material, ternary lithium

batteries are divided into NCA and NCM. NCM means that the positive electrode

material is composed of three materials of nickel, cobalt and manganese in a

certain proportion, while the positive electrode material of NCA is composed of

nickel, cobalt and aluminum. The strong battery life claimed by Tesla this time

belongs to the ternary lithium NCA battery.

Zhou Bo, director of the Research Department of the Power Battery

Application Branch of the China Chemical and Physical Power Supply Industry

Association, said that the production process conditions of NCA are more

demanding, and there are barriers to the production process. More importantly,

the technical barriers of NCA materials are also very high. At present,

production capacity is mainly concentrated in Japan and South Korea, while mass

production in my country is relatively small.

"NCA batteries can also be made in China. Last year, a key domestic

material company supplied more than 1,000 tons of Panasonic." Zhang Yu said.

However, according to the reporter's understanding, the industrial

development of domestic NCA materials and batteries started late. At present,

many companies have started pilot trials and small batch trials. There are still

some technical problems that need to be resolved, and mass production and sales

have not been formed. At the same time, production materials are limited, and

the foreign NCA material market is mainly monopolized by Sumitomo Metals and

Japan Chemical Industry Co., Ltd.

Zhang Yu analyzed that the deep-seated reason why NCA batteries have not

been mass-produced in China is that the safety of batteries has declined due to

poor thermal stability, and battery manufacturers and end product users have

concerns about the safety of NCA batteries. This requires reliable and safe

design of the system from cell design, power supply system design, and power

supply use. From a processing perspective, NCA batteries require a pure oxygen

environment and high processing costs. The humidity must be controlled below 10%

during the entire battery production process, which poses great challenges to

domestic enterprises.

Based on the factors of technology, cost and subsidies, China mainly chose

the NCM route, but this does not mean that there are no new opportunities for

the NCA route.

Cost affects the market Tesla may not be the benchmark

Although local Chinese companies are not unable to produce ternary lithium

batteries, Tesla's challenge to the limit of ternary lithium batteries is not

necessarily the only goal of my country's new energy vehicle battery research

and production.

According to data from the Power Battery Application Branch of China

Chemical and Physical Power Supply Industry Association, from the perspective of

different battery material types, the installed capacity of ternary lithium

batteries from January to December 2017 was 16.04 gigawatt-hours, accounting for

44. 01%; the installed capacity of lithium iron phosphate batteries is 17.97

gigawatt-hours, accounting for 49.29%; the installed capacity of lithium

manganate batteries is 1.48 gigawatt-hours, accounting for 4.06%...

Industry insiders told reporters that under the guidance of national

policies and the blessing of the market environment, my country’s lithium

battery technology route is both lithium iron phosphate and ternary lithium

batteries. However, even in the development of the technical route of the

ternary lithium battery, the choice of domestic power battery manufacturers is

also focused. There are many people who choose the NCM route, and few choose the

NCA route used by Tesla.

NCA batteries have been mass-produced on a large scale and mature, and have

been commercially verified; while high-energy-density NCM batteries have not yet

been mass-produced. Industry experts said that the performance of the two is

relatively close, but the price of the high energy density NCM is slightly

cheaper. Therefore, in terms of cost performance, NCM is more in line with the

Chinese market.

"In a sense, it is actually lithium iron phosphate that has made China's

new energy vehicles. From a cost perspective, lithium iron phosphate is more

dominant. We predict that the market for lithium iron phosphate batteries in the

future should be more than that of ternary lithium batteries. Big.” The current

development trend of ternary lithium batteries benefited from the national

policy-oriented requirements for high specific energy batteries, which require

batteries with high energy density and long cruising range. Of course, the

ternary lithium battery has a higher specific energy and specific power, which

is more in line with the needs of passenger cars, but it may not necessarily be

the mainstream of the market in the future.