Li-ion battery safety issues&technology

1. The dangers of lithium-ion batteries

a. High chemical activity

Lithium is an element of main group I of the second period of the periodic

table and has extremely active chemical properties.

b. High energy density

Lithium-ion batteries have a very high specific energy (≥140Wh/kg), which

is several times that of nickel-cadmium, nickel-hydrogen and other secondary

batteries. If a thermal runaway reaction occurs, it will release a high amount

of heat and easily lead to unsafe behavior.

c. Use organic electrolyte system

Organic solvents are hydrocarbons, have low decomposition voltage, are

prone to oxidation, and the solvent is flammable; if leakage occurs, it will

cause the battery to catch fire, or even burn or explode.

d. High probability of side reactions

During normal use of lithium-ion batteries, under certain conditions, such

as overcharging, overdischarging or overcurrent operation, it is easy to cause

chemical side reactions inside the battery, which will seriously affect the

performance and service life of the battery, and A large amount of gas may be

generated, causing the pressure inside the battery to rapidly increase and then

explode and fire, causing safety problems.

e. The structure of the electrode material is unstable

The overcharge reaction of lithium-ion batteries will change the structure

of the positive electrode material and cause the solvent in the electrolyte to

be strongly oxidized; and this effect is irreversible, and the heat generated by

the reaction may cause thermal runaway.

2. Analysis of the causes of safety problems of lithium-ion battery

products

After 30 years of industrial development, lithium-ion battery products have

made considerable progress in safety technology, effectively controlling the

occurrence of side reactions in the battery and ensuring the safety of the

battery. However, with the increasing use of lithium-ion batteries and higher

energy density, safety incidents have occurred frequently in recent years.

We conclude that the main reasons for the safety problems of lithium-ion

battery products are as follows:

a. Material issues

When selecting materials, the manufacturer did not conduct a certain

assessment of the raw materials, which caused the inherent deficiencies in the

safety of the batteries.

b. Production process issues

The raw materials are not strictly tested and the production environment is

poor, resulting in the mixing of impurities in the production, which not only

has a great disadvantage to the capacity of the battery, but also has a great

impact on the safety of the battery; in addition, if too much water is mixed in

the electrolyte, Side reactions may occur and increase the internal pressure of

the battery, which will affect safety.

c. Defects in battery cell design and reduced safety performance

In terms of structural design, there is no insulating tape in key parts, or

insufficient margin, unreasonable design of the length of the tab, etc., all of

which may bury hidden dangers to the safety of the battery.

d. The energy density is too high

At present, the market is pursuing higher-capacity battery products. In

order to increase product competitiveness, manufacturers continue to increase

the volumetric specific energy of lithium-ion batteries, which greatly increases

the risk of batteries.

Three, security technology

Although lithium-ion batteries have many hidden dangers, the use of certain

measures can effectively ensure their safety.

The following briefly introduces several commonly used safety technologies

for lithium-ion batteries.

a. Choose raw materials with higher safety factor

b. Strengthen the overall safety design of the battery cell

1) Using switching elements, when the temperature in the battery rises, its

resistance rises, and when the temperature is too high, it will automatically

stop power supply;

2) Set up a safety valve (that is, the vent on the top of the battery).

When the internal pressure of the battery rises to a certain value, the safety

valve will automatically open to ensure the safety of the battery.

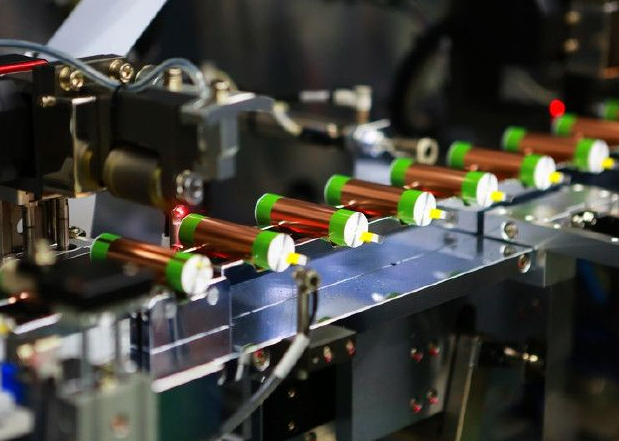

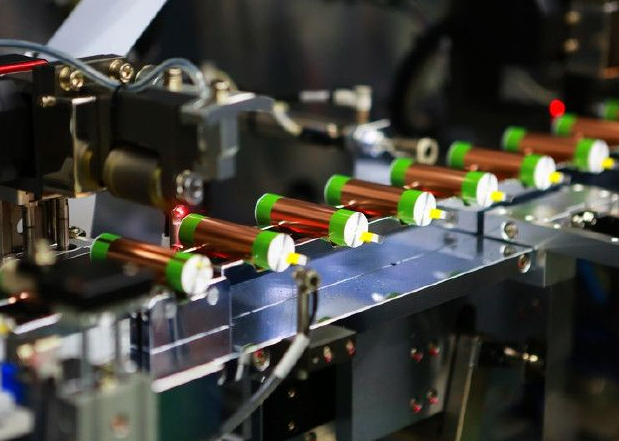

c. Improve process level

Efforts to standardize and standardize the production process of batteries,

improve process methods, do a good job of process control, ensure process

quality, reduce differences between products, implement standardized quality

monitoring, eliminate defective parts, and eliminate defective products;

maintain the production site Tidy and clean, implement 5S management and 6-sigma

quality control to prevent impurities and moisture from being mixed in

production, and minimize the impact of accidents in production on safety.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

substitute for lead-acid batteries, and are the first choice for grid-connected

peak shaving, off-grid energy storage, photovoltaic energy storage, UPS, data

center and other industries.