The charging process of lithium-ion batteries can be divided into three

stages: trickle charging (low-voltage precharge), constant current charging, and

constant voltage charging.

The charging process of lithium-ion batteries can be divided into three

stages: trickle charging (low-voltage precharge), constant current charging, and

constant voltage charging.

The charging method of the lithium battery is voltage-limiting and constant

current, which is controlled by the IC chip. The typical charging method is:

first detect the voltage of the battery to be charged, if the battery is

If the voltage is lower than 3V, it must be pre-charged first. The charging

current is 1/10 of the set current. After the voltage rises to 3V, it enters the

standard charging process. The standard charging process is:

Perform constant current charging with the set current. When the battery

voltage rises to 4.20V, change to constant voltage charging and keep the

charging voltage at 4.20V. At this time, the charging current gradually

decreases

Decrease, when the current drops to 1/10 of the set charging current,

charging ends.

Everyone already knows that the cathode material of lithium-ion batteries

is lithium cobalt oxide and the anode is carbon.

The working principle of lithium-ion battery refers to its charging and

discharging principle. When the battery is charged, lithium ions are generated

on the positive electrode of the battery, and the generated lithium ions move to

the negative electrode through the electrolyte. The carbon as the negative

electrode has a layered structure. It has many micropores. The lithium ions that

reach the negative electrode are embedded in the micropores of the carbon layer.

The more lithium ions are inserted, the higher the charging capacity.

Similarly, when the battery is discharged (that is, when we use the

battery), the lithium ions embedded in the carbon layer of the negative

electrode are released and move back to the positive electrode. The more lithium

ions returned to the positive electrode, the higher the discharge capacity. What

we usually call battery capacity refers to discharge capacity.

It is not difficult to see that during the charging and discharging process

of lithium-ion batteries, lithium ions are in a state of movement from positive

→ negative → positive. If we compare the lithium ion battery to a rocking chair,

the two ends of the rocking chair are the two poles of the battery, and the

lithium ion is like an excellent athlete running back and forth on the two ends

of the rocking chair. Therefore, the experts gave the lithium-ion battery a

lovely name, rocking chair battery.

Lithium battery charging circuit principle and application

Lithium-ion batteries are widely used in mobile phones, camcorders,

notebook computers, cordless phones, power tools, remote control or electric

toys, cameras and other portable electronic devices due to their excellent

characteristics.

1. Lithium batteries and Ni-Cd and Ni-MH rechargeable batteries:

The negative electrode of a lithium ion battery is graphite crystal, and

the positive electrode is usually lithium dioxide. During charging, lithium ions

move from the positive electrode to the negative electrode and are embedded in

the graphite layer. When discharging, lithium ions depart from the surface of

the negative electrode in the graphite crystal and move to the positive

electrode. Therefore, during the charging and discharging process of the

battery, lithium always appears in the form of lithium ions, rather than in the

form of metallic lithium. Therefore, this kind of battery is called a lithium

ion battery, or lithium battery for short.

Lithium batteries have the advantages of small size, large capacity, light

weight, no pollution, high single-cell voltage, low self-discharge rate, and

many battery cycles, but they are more expensive. Nickel-cadmium batteries are

being phased out due to low capacity, serious self-discharge, and pollution to

the environment. Ni-MH battery has a higher cost performance and does not

pollute the environment, but the single voltage is only 1.2V, so the scope of

use is limited.

2. The characteristics of lithium batteries:

1. Higher weight-to-energy ratio and volume-to-energy ratio;

2, the voltage is high, the voltage of a single lithium battery is 3.6V,

which is equal to the series voltage of 3 nickel-cadmium or nickel-metal hydride

rechargeable batteries;

3, self-discharge is small and can be stored for a long time, this is the

most prominent advantage of the battery;

4. No memory effect. Lithium batteries do not have the so-called memory

effect of nickel-cadmium batteries, so there is no need to discharge lithium

batteries before charging;

5. Long life. Under normal working conditions, the number of

charge/discharge cycles of lithium batteries is far greater than 500;

6. It can be charged quickly. Lithium batteries can usually be charged

with a current of 0.5 to 1 times the capacity, shortening the charging time to 1

to 2 hours;

7, can be used in parallel at will;

8. Because the battery does not contain heavy metal elements such as

cadmium, lead, mercury, etc., it has no pollution to the environment and is the

most advanced green battery in the contemporary era;

9. High cost. Compared with other rechargeable batteries, lithium batteries

are more expensive.

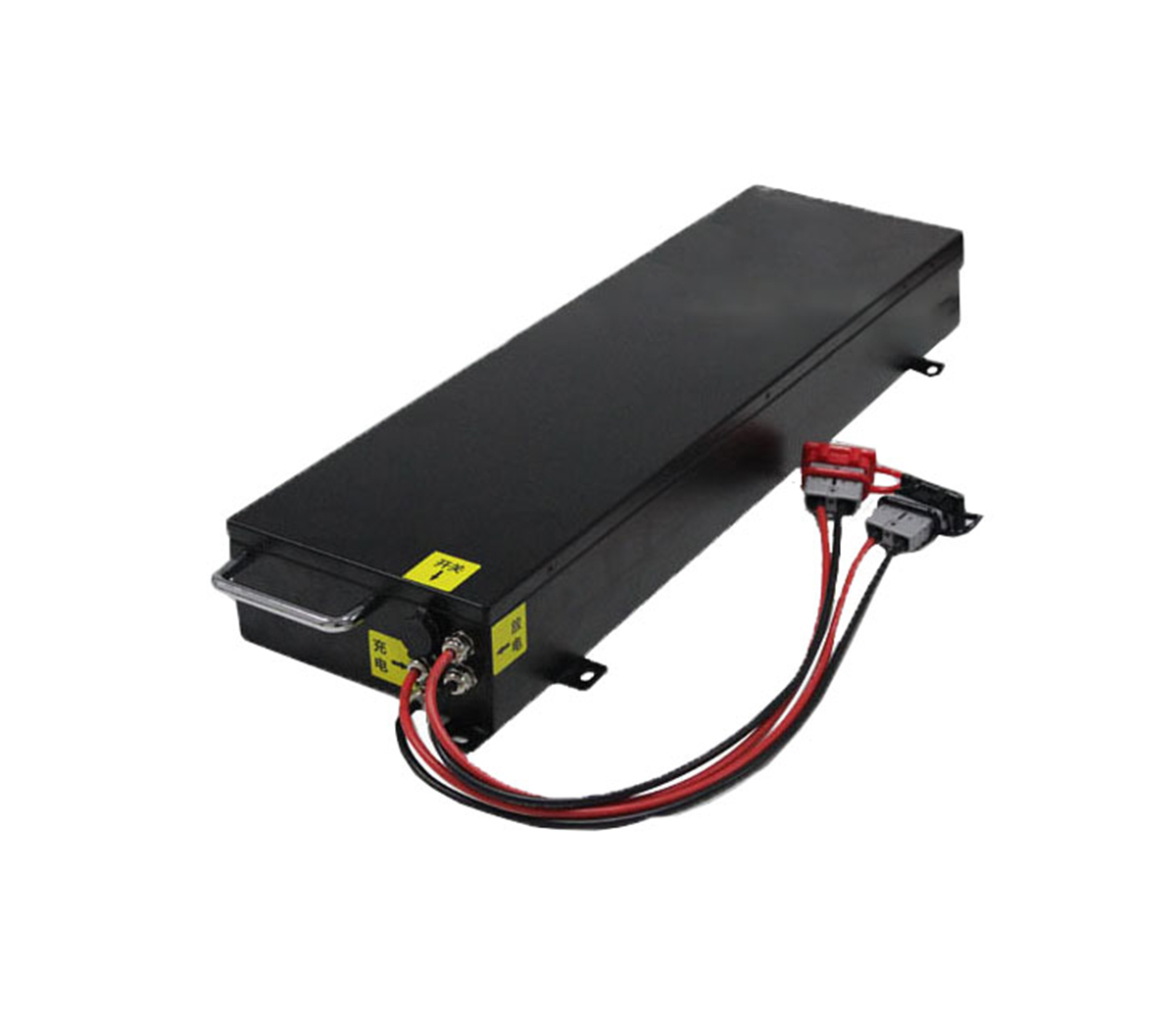

Three, the internal structure of the lithium battery:

Lithium batteries usually have two appearances: cylindrical and

rectangular.

The inside of the battery adopts a spiral wound structure, which is made of

a very fine and highly permeable polyethylene film separator between the

positive and negative electrodes. The positive electrode includes a lithium ion

collector composed of lithium and cobalt dioxide and a current collector

composed of aluminum thin film. The negative electrode is composed of a lithium

ion collector made of sheet carbon material and a current collector made of

copper thin film. The battery is filled with an organic electrolyte solution. In

addition, a safety valve and PTC components are installed to protect the battery

from damage when the battery is abnormal and the output is short-circuited.

The voltage of a single-cell lithium battery is 3.6V, and the capacity

cannot be infinite. Therefore, single-cell lithium batteries are often processed

in series or parallel to meet the requirements of different occasions.

Fourth, the charging and discharging requirements of lithium batteries;

1. Lithium battery charging: According to the structural characteristics of

the lithium battery, the highest end-of-charge voltage should be 4.2V, and it

cannot be overcharged. Otherwise, too much lithium ions from the positive

electrode will be taken away and the battery will be scrapped. The charging and

discharging requirements are relatively high, and a dedicated constant current

and constant voltage charger can be used for charging. Normally, the constant

current charge to 4.2V/cell will switch to constant voltage charge. When the

constant voltage charge current drops to less than 100mA, the charge should be

stopped.

Charging current (mA)=0.1~1.5 times battery capacity (such as 1350mAh

battery, its charging current can be controlled between 135~2025mA). The normal

charging current can be selected at about 0.5 times the battery capacity, and

the charging time is about 2 to 3 hours.

2. Lithium battery discharge: Due to the internal structure of the lithium

battery, all lithium ions cannot move to the positive electrode during

discharge. Some lithium ions must be retained in the negative electrode to

ensure that lithium ions can be inserted into the channel smoothly during the

next charge. Otherwise, the battery life will be shortened accordingly. In order

to ensure that some lithium ions remain in the graphite layer after discharge,

it is necessary to strictly limit the minimum discharge termination voltage,

which means that the lithium battery cannot be over-discharged. The final

discharge voltage is usually 3.0V/cell, and the minimum should not be lower than

2.5V/cell. The length of battery discharge time is related to battery capacity

and discharge current. Battery discharge time (hours) = battery

capacity/discharge current. Lithium battery discharge current (mA) should not

exceed 3 times the battery capacity. (Such as 1000mAH battery, the discharge

current should be strictly controlled within 3A) Otherwise, the battery will be

damaged.

The current lithium battery packs sold on the market are equipped with a

matching charge and discharge protection board. Just control the external charge

and discharge current.

5. Lithium battery protection circuit:

The charging and discharging protection circuit of two lithium batteries is

shown in Figure 1. It is composed of two FETs and a dedicated protection

integrated block S-8232. The overcharge control tube FET2 and the overdischarge

control tube FET1 are connected in series in the circuit, and the battery

voltage is monitored and controlled by the protection IC. When the battery

voltage rises to 4.2V , The overcharge protection tube FET1 is turned off and

charging is stopped. In order to prevent malfunction, a delay capacitor is

generally added to the external circuit. When the battery is in a discharging

state, when the battery voltage drops to 2.55V, the over-discharge control tube

FET1 is cut off, and the power supply to the load is stopped. Over current

protection is to control FET1 to cut off and stop discharging to the load when a

large current flows through the load. The purpose is to protect the battery and

the field effect tube. Overcurrent detection uses the on-resistance of the field

effect tube as the detection resistance, monitors its voltage drop, and stops

discharging when the voltage drop exceeds the set value. A delay circuit is

generally added to the circuit to distinguish between surge current and

short-circuit current. The circuit has perfect functions and reliable

performance, but it is highly professional, and the dedicated integrated block

is not easy to buy, and it is not easy to imitate by amateurs.