How does helium leak detection technology help improve the consistency of

power battery production?

In fact, in addition to batteries, PACKs and materials, the quality of

battery manufacturing and new energy vehicles also depends on the safety and

reliability of battery manufacturing equipment. Among them, helium leak

detection technology is an indispensable link in the production process of power

batteries.

The lithium battery industry is a technologically innovative industry,

especially when the performance of power batteries needs to be improved. All

links of the industry chain are spent on improving the energy density of power

batteries, and good results have been achieved. In fact, in addition to

batteries, PACKs and materials, the quality of battery manufacturing and new

energy vehicles also depends on the safety and reliability of battery

manufacturing equipment. Among them, helium leak detection technology is an

indispensable link in the production process of power batteries.

So, how does helium leak detection technology help improve the consistency

of power battery production?

On May 21, the "OFweek2018 (Second) China Power Lithium Battery Technology

and Application Seminar" hosted by OFweek China's high-tech industry portal and

undertaken by OFweek Lithium Grid will be held in Shenzhen, Afak Oriental Vacuum

() Co., Ltd. Qu Qilong, Chief of the R&D Section of the Institute of New

Technology, will give a speech on "Application of Helium Leak Detection

Technology in Power Battery Industry". Let the industry understand the

importance of more application solutions of helium leak detection technology in

the power battery industry and the improvement of equipment technology level for

battery manufacturing under the new industry background.

As the development of new energy vehicles has risen to a national strategy,

the current development of the automotive industry has ushered in opportunities

and turning points. Behind the new opportunities, the upstream power battery

industry is facing opportunities and challenges. The traditional extensive

capital investment can no longer meet the needs of competition, and only by

upgrading the technology and strictly controlling the quality of the products

can it develop by leaps and bounds. The national subsidy policy is tilted

towards higher energy density power batteries, which also puts forward new

requirements for the testing of new energy vehicles and power batteries.

This seminar will start with the direction of power battery upstream

materials, production process and product testing, technological innovation,

intelligent manufacturing and industrial applications, and will conduct in-depth

discussions on new energy vehicle technology and battery technology, and talk

about the development of my country's power battery industry. Opportunities and

challenges.

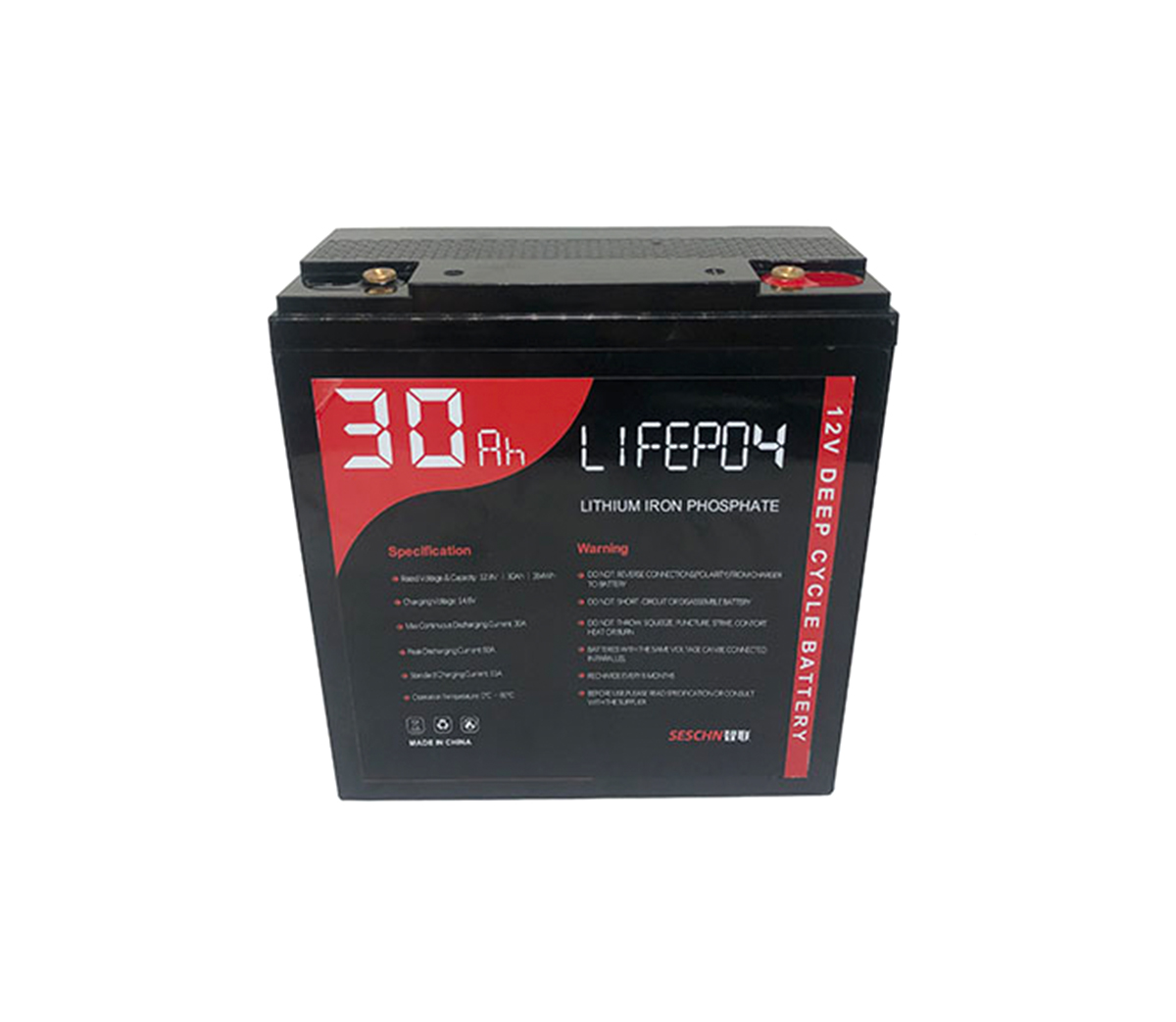

It is understood that Aifa Branch Oriental Vacuum () Co., Ltd. is a

world-renowned vacuum company. Its main equipment includes vacuum box online

leak detection device, helium filling and recovery device, refrigerant filling

device, explosion-proof filling machine, ultra-high vacuum Exhaust station,

vacuum valve, EBA series indirect evaporation coating device, EWA series vacuum

winding coating device, car lamp coating equipment, high-pressure helium

inspection, helium concentration meter, leak detector, ion pump, etc.

At present, the helium inspection and filling equipment of AFFCO in the

automotive field is widely used in equipment such as new energy automobile

air-conditioning compressors, automobile wheels, automobile air-conditioning

liquid storage tanks, and automobile torque converters. It is enough to realize

automatic sealing of the battery and other workpieces; the equipment is

connected with the assembly line to improve the degree of automation; the helium

recovery system improves the recovery rate and reduces the use cost.

It is worth noting that this conference will focus on the hottest topics in

the industry and discuss solutions to problems in industry development. Invite

experts and professors from the power battery industry such as the School of

Materials Science, Shenzhen University, Watermark, Guoxuan High-tech, Festo,

South China University of Technology, Massachusetts Solid Energy Company,

Shenzhen West Lake New Energy Transportation Development Co., Ltd., OFweek

Industry Research Center, etc. Business managers, analysts and other industry

professionals will give wonderful speeches from multiple perspectives such as

the price trend and selection of power battery materials, the application of

production equipment in the power battery industry, the current situation and

future development of lithium battery separator materials, and further discuss

power Other latest technologies and solutions in the battery industry.