Lithium-ion batteries work by relying on lithium ions to move back and forth between the positive and negative electrodes. During charging, the potential applied to the two poles of the battery forces the compounds of the positive electrode to release lithium ions, which travel through the separator to the carbon where the molecules of the negative electrode are arranged in a lamellar structure. During discharge, lithium ions are precipitated from the carbon in the lamellar structure and recombine with the compound of the positive electrode, and the movement of lithium ions generates an electric current.

Driven by the rapid growth of electric vehicles, the global lithium battery industry continues to maintain a rapid growth trend, industry innovation continues to accelerate, new products and new technologies continue to emerge, and various new battery technologies have emerged one after another.

SES Power is a professional lithium battery energy storage system integrator with nearly 20 years of experience. Our products have high technical content and high cost performance: such as lead-acid replacement products with Bluetooth or RS485 communication function (phosphoric acid) Iron lithium battery 12V100Ah, 12V200Ah, 24V100Ah), high current (2000A) starting lithium battery, UPS high voltage lithium battery system (up to 860V), 3Kw~20Kw off-grid, grid-connected, island-type lithium battery energy storage system, wall-mounted home Energy storage system 48V100Ah, 48V200Ah, stacked energy storage system (single is 51.2V100Ah, supports up to 15 stacks) and so on.

We are full of confidence in the development of the lithium battery industry. Let us sort out the development status and trends of China's lithium battery industry for you. Through these data, we can draw some good conclusions.

A: China's lithium battery development status

After decades of development, China's lithium battery industry has made great breakthroughs in both quantity and quality, and many companies with global competitiveness have been born.

In 2021, China's lithium battery shipments will reach 229GW, and it is expected that shipments will reach 610GW in 2025, with a compound annual growth rate of more than 25%.

SES Power has analyzed the lithium battery market in recent years, and it mainly has the following characteristics:

a1: Market size continues to grow

From 2015 to 2020, the scale of China's lithium-ion battery market continued to grow, from 98.5 billion yuan to 198 billion yuan, and to 312.6 billion yuan in 2021.

Affected by factors such as price, the growth rate has slowed recently, with the year-on-year growth rate dropping from 37.76% to 13.14% in 2020.

Calculated by capacity, China's lithium-ion battery output in 2020 is 148GWh, a year-on-year increase of 19.2%, but by 2021, the output will reach 324GWh, a year-on-year increase of 118.9%, and the output is growing rapidly.

From 2016 to 2021, China's lithium-ion battery production has increased from 8.47 billion to 23.26 billion, but the year-on-year growth rate has dropped from 51.3% to 23.4%.

a2: Power battery accounts for a large proportion and grows faster

In 2021, the output of consumption, power and energy storage lithium batteries will be 72GWh, 220GWh and 32GWh respectively, up 18%, 165% and 146% year-on-year respectively, accounting for 22.22%, 67.9% and 9.88% respectively. fastest growing.

Among the power batteries, lithium iron phosphate batteries account for a high proportion. In 2021, the total output of lithium iron phosphate batteries is 125.4GWh, accounting for 57.1% of the total output, with a cumulative increase of 262.9% year-on-year.

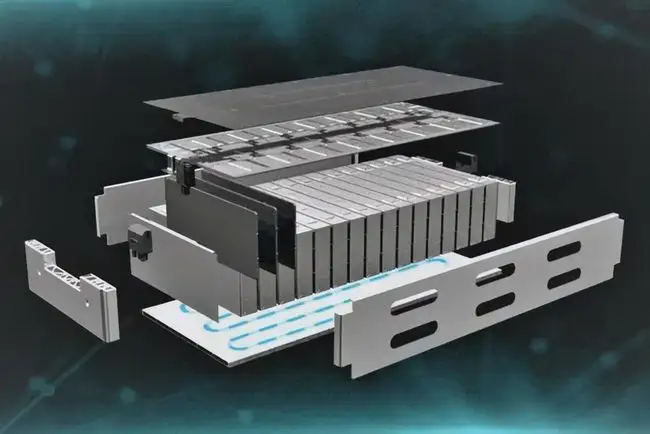

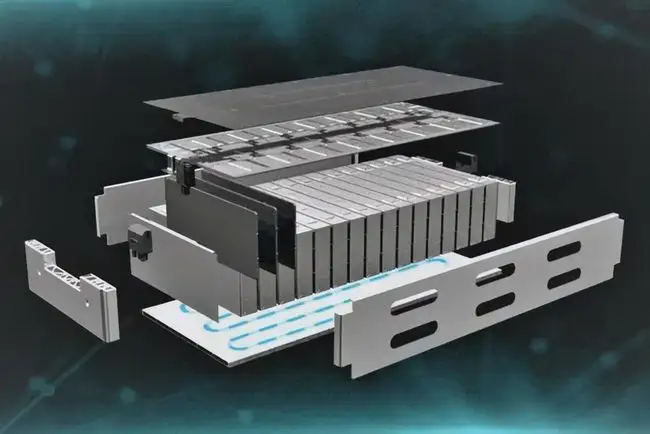

a3: Square cells gradually dominate

The prismatic battery is the most cost-effective, and has now occupied the mainstream of the Chinese market. In 2021, the market share of the prismatic lithium battery will be about 80.8%.

Soft-pack battery cells have the highest energy density, but because the aluminum-plastic film is easily damaged, the battery pack needs to be equipped with more protective layers, resulting in a lack of overall energy density. About 9.5%.

The round battery has the lowest cost, but the energy density is low. Fewer companies choose this type of battery, so the market share is about 9.7%.

a4: Upstream raw material cost fluctuates greatly

Affected by multiple factors such as the industrial cycle, the epidemic, and international tensions, the cost of upstream raw materials for power batteries will continue to increase in 2022.

The price of battery-grade lithium carbonate has been soaring, from 41,600 yuan / ton in 2013 to 474,900 yuan / ton in June 2022, especially in 2022, the price increase is high, and the price increase in June 2022 is as high as 425.3%.

B: Material Market Status of Lithium Batteries

Lithium-ion batteries generally use lithium alloy metal oxides as positive electrode materials, graphite as negative electrode materials, and use non-aqueous electrolytes. Specifically, it can be divided into positive electrode material, negative electrode material, electrolyte, diaphragm, aluminum-plastic film, etc.

b1: positive electrode material

The positive electrode material of lithium battery is the decisive factor of its electrochemical performance, which plays a leading role in the energy density and safety performance of the battery, and the cost of positive electrode material is also relatively high, accounting for 30%-40% of the cost of lithium battery material. Materials are the most critical materials for lithium batteries.

Lithium batteries are divided according to the cathode material system, which are mainly divided into technical routes such as lithium cobalt oxide, lithium manganate, lithium iron phosphate, and ternary materials.

Lithium cobalt oxide has high cost and short life, and is mainly used in 3C products; lithium manganate has low energy density, short life but low cost, and is mainly used in special vehicles; lithium iron phosphate has long life, good safety and low cost, mainly used in commercial vehicles; ternary materials, especially NCM, have high energy density, good cycle performance and long life, and are mainly used in passenger vehicles.

At present, ternary lithium batteries and lithium iron phosphate batteries are the mainstream routes in the industry. Benefiting from the growth of electric vehicles and energy storage markets, lithium iron phosphate will become the fastest growing cathode material in the next five years.

b2: negative electrode material

Anode materials are an important part of lithium-ion batteries. It mainly affects the capacity, first efficiency, cycle performance, etc. of lithium batteries.

The negative electrode material is made of negative electrode active material, binder and additives mixed into a paste and evenly spread on both sides of the copper foil, and is formed by drying and rolling. Anode materials account for about 5% to 15% of the cost of power batteries.

At present, the anode materials of lithium batteries are mainly artificial graphite and natural graphite, and the development trend is to dope silicon into the graphite anode to form a silicon-based anode with higher energy density. At this stage, artificial graphite is the mainstream route for negative electrodes. Silicon-based materials have great application potential, and the future market space is broad.

In 2021, China's lithium battery anode market shipments will be 720,000 tons, a year-on-year increase of 97%. As the consistency and cycle performance of artificial graphite is better than that of natural graphite, and it is more suitable for the needs of power and energy storage batteries, the proportion of artificial graphite production and shipments has continued to increase to 84%, while the market share of natural graphite has dropped to 14%.

b3: Electrolyte

The electrolyte is the carrier of ion transport in the battery, specifically, it plays the role of conducting ions between the positive and negative electrodes of the lithium battery, and is the guarantee for the lithium ion battery to obtain the advantages of high voltage and high specific energy.

Lithium battery electrolyte is generally prepared from high-purity organic solvent, electrolyte lithium salt, necessary additives and other raw materials under certain conditions and in a certain proportion. Among them, according to their different structures, organic solvents can be divided into the main components are lithium hexafluorophosphate, ethylene carbonate, phosphorus pentafluoride and so on.

At present, the concentration of China's lithium battery electrolyte industry is relatively high, and the concentration of the top three companies in the industry exceeds 60%. At the same time, in recent years, China's leading lithium-ion battery electrolyte enterprises have continued to invest in building factories and expanding production. The industry competition pattern is stable and the concentration is being further improved.

b4: Diaphragm

Separator is one of the raw materials of lithium battery. It is located between the positive and negative electrodes inside the battery to ensure the passage of lithium ions while hindering the transmission of electrons. It is a thin film with a microporous structure and is the key inner layer component with the most technical barriers in the lithium ion battery industry chain.

The performance of the separator determines the interface structure and internal resistance of the battery, which directly affects the capacity, cycle and safety performance of the battery. The excellent performance of the separator plays an important role in improving the comprehensive performance of the battery.

The separator production process is complex, the capital investment is large, and it requires long-term research and development and production experience accumulation.

In recent years, driven by the growth in demand for lithium batteries, lithium battery separators have also achieved rapid growth in shipments. Data shows that in 2021, China's lithium battery diaphragm shipments will be 7.8 billion square meters, a year-on-year increase of more than 100%.

b5: copper foil

Copper foil is used as the negative electrode current collector of lithium ion battery and acts as the carrier of negative electrode active material. It does not account for a high proportion of the cost of lithium batteries, about 5-10%, but it has an important impact on the overall performance of the battery.

Therefore, lithium copper foil is an important part of lithium batteries that cannot be ignored. According to different thickness, lithium battery copper foil can be divided into thin copper foil (12-18 microns), ultra-thin copper foil (6-12 microns) and ultra-thin copper foil (6 microns and below). Since new energy vehicles have higher requirements on energy density, power batteries tend to use ultra-thin and ultra-thin copper foils with thinner thicknesses.

Benefiting from the rapid development of China's new energy vehicle and lithium battery industry, China's lithium battery copper foil development is in a leading position in the world. At present, China's 6-nanometer lithium battery copper foil market is relatively broad, but the traditional 7-8 nanometer copper foil market is highly competitive.

C: Prediction of the development of the lithium battery market in the next two or three years

At present, the impact of the epidemic on the production side has gradually eased. According to downstream sales and upstream capacity utilization, lithium batteries are still in short supply, and companies have expanded production capacity.

In terms of raw materials, new energy vehicles are more sensitive to cost, and the demand for lithium iron phosphate is stronger than that of ternary, and the price will remain high.

At present, the price of battery cells has risen. Considering the increasing demand for energy storage in the lithium battery sector, the lithium battery industry chain will continue to develop rapidly in the later period.

c1: The explosion of energy storage applications has formed a trend of simultaneous growth with EVs

In 2021, the global energy storage battery shipments will be 203.5GW, and China's shipments will be 43.44GW, accounting for 21.3%. With the development of the energy crisis, the demand for energy storage is becoming more and more urgent. According to a third-party forecast, the global lithium battery shipments will reach 1,218GW in 2025, and energy storage will account for 36%.

c2: The proportion of square batteries continues to rise

The proportion of power square batteries has further increased, energy storage batteries are dominated by square aluminum shell lithium iron phosphate, and the production progress of cylindrical 4680 batteries has accelerated.

c3: EV battery market concentration continues to increase

As the first echelon of CATL and BYD, the market share will exceed 70%.

c4: There is still a gap between the supply and demand of upstream raw materials

Lithium iron phosphate, which accounts for the largest proportion, is due to insufficient production capacity, limited new production capacity, and tight demand; the electrolyte gap is further expanded, and the expected price range is 100,000-150,000 yuan / ton, the largest increase.

c5: Core technologies such as sodium-ion batteries and solid-state batteries are still breaking through

Affected by raw material resources and costs, such batteries have received a high level of attention, but it is difficult to achieve mass production in a short period of time and cannot compete with lithium batteries.

D: Prediction of the development of lithium battery technology in the next two or three years

It is an indisputable fact that new technologies in the lithium battery industry will gradually mature under the market demand.

d1: Accelerated maturation of new technologies

For example, the module-free design of lithium batteries, blade batteries, clip batteries and other system structure innovations will greatly improve production efficiency, and cutting-edge technologies such as high-nickel cobalt-free batteries and solid-state/semi-solid-state batteries will continue to make breakthroughs.

With the advancement of technology, the energy level of lithium batteries continues to climb. The energy density of the ternary prismatic battery is close to 300Wh/kg, and the soft pack battery has reached 330Wh/kg; the energy density of the semi-solid battery has also exceeded 360Wh/kg, and it is expected to achieve 400Wh/kg by 2025; in the future, the energy density of the lithium-sulfur battery is expected to reach 600Wh/kg.

At the same time, high-nickel and lithium-rich manganese-based cathode materials with higher specific energy will become a major development direction, because it can meet the requirements of passenger cars with a cruising range of 1000km and electric aircraft requirements; in addition, based on modified lithium manganate, The cathode materials of lithium iron phosphate and nickel manganese spinel are matched with high-capacity anode materials to form a solution for the battery life of 600 kilometers of pure electric vehicles.

d2: Lithium battery recycling will form a scale

Lithium batteries have high recycling value, and retired batteries can still be recycled and upgraded before being put into use. Even end-of-life lithium batteries can be recycled for their lithium cobalt nickel resources.

The recycling of metals in cathode materials and the recycling of aluminum and copper in batteries are not only critical to the security of the supply chain, but also of great significance to the achievement of carbon emission goals.

According to the estimates of relevant institutions, the recycling of battery materials will form a scale in 2030; around 2050, the supply of original mineral resources and recycled resources will reach a considerable level. In the longer term, recycled resources will gradually completely replace the demand for original resources.

d3: Lightweight, high energy density, high safety and fast charging are important development directions for the future industry

In recent years, consumer electronic products have developed in the direction of fashion and thinning, ergonomic shape design and mobile interconnectivity. In the context of the expansion of radio frequency frequency bands, pixel density improvement, and enhanced processor performance of consumer electronic products, consumer electronics the energy consumption and heat generation problems of electronic products are also increasingly prominent, and the demand for lithium-ion batteries with light weight, small size, large capacity, high energy density, customizable size, good safety performance and fast charging is increasing.

At the same time, in the face of the rapid development of electric vehicles and energy storage markets, the performance of power batteries in terms of high safety, high specific energy, long life and fast charging has attracted consumers' attention.

d4: Technological advances further drive alternative actions

This is also a direction that SES Power is very concerned about: electric bicycles and low-speed electric vehicles will increasingly use lithium-ion batteries to replace traditional lead-acid batteries; in the field of energy storage battery applications, lithium batteries will replace lead-acid batteries in UPS, The status of data centers, grid energy storage, base station backup power, and home solar energy storage systems.

As a dynamic and experienced professional lithium battery R&D and production manufacturer, SES Power has a deep understanding of lithium battery products. If you have any questions about lithium batteries, home energy storage, and power systems, you are welcome to contact us.