Tesla Mega pack, a large-capacity energy storage battery, enables power companies to transmit and store redundant power across regions and use stored power resources when local electricity demand is high or when there are unexpected power outages on the grid.

As a world-renowned new energy product company, Tesla's lithium battery products span two major areas: power and energy storage. Among them, Mega Pack has excellent performance, so it has been favored by many investors. However, Tesla's safety accidents have occurred from time to time.

As a professional manufacturer with nearly two decades of research, development and manufacturing of lithium battery energy storage systems, SES Power always puts safety first, even though our products are made of high-quality square lithium iron phosphate batteries. We are confident in the development of the energy storage industry, so let us sort out for you how we should look at the several fires of Tesla's Mega Pack when there are safety incidents of Tesla.

A: On September 21, there was another Mega Pack energy storage battery fire in the United States

The fire at the Tesla Megapack energy storage battery facility in Monterey, California, operated by Pacific Gas and Electric Company (PG&E), started early Tuesday morning, Sept. 21, local time, and as of 2 p.m. local time Tuesday, the open fire had not been fully extinguished at the site.

PG&E is working with fire and emergency services to create enough containment to safely stop the fire from spreading, said PG&E spokesman Jeff Smith, who said the company discovered the fire at 1:30 a.m. local time on Sept. 20, and that the fire did not cause any injuries at the site. As of noon Tuesday, PG&E had no power interruptions due to the fire.

In April, PG&E opened the 182.5 MW Tesla Megapack Energy Storage System, also known as the "Elkhorn Battery Storage System," in Moss Landing, Monterey.

The energy storage facility is owned and operated by PG&E, but designed, built and maintained by Tesla and PG&E. Smith emphasized that PG&E does not expect the fire to cause any power interruptions to customers.

There are two different energy storage projects in Moss Landing, Monterey. One is operated by PG&E and the other is operated by Texas-based Vistra.

On Tuesday, a spokesman for Vistra said their energy storage facility was not affected by the incident. Earlier this year, two overheating events occurred at Vistra's locally located energy storage batteries, and in July, "after implementing identified corrective measures," Vistra restarted the storage facility and operated it at about 98 percent of its maximum capacity.

Following the fire, the California Highway Patrol closed a portion of Highway 1 and rerouted nearby traffic for several hours. The California Highway Patrol tweeted on social media at 4:30 p.m. Tuesday that the freeway closure had been extended due to air quality concerns, and there is no specific time frame for reopening. Some residents near the energy storage battery project have also been told to close their doors and windows and shelter in place in light of the fire, which will produce harmful fumes.

B: Tesla is accelerating the deployment of energy storage systems, but safety incidents are not uncommon

This energy storage battery fire in Monterey, California is reminiscent of the previous Tesla Megapacks energy storage battery fire in Australia.

These fires have highlighted a number of challenges still facing people in adopting new technologies to improve grid efficiency and make more use of intermittent renewable resources such as wind and solar to generate energy storage.

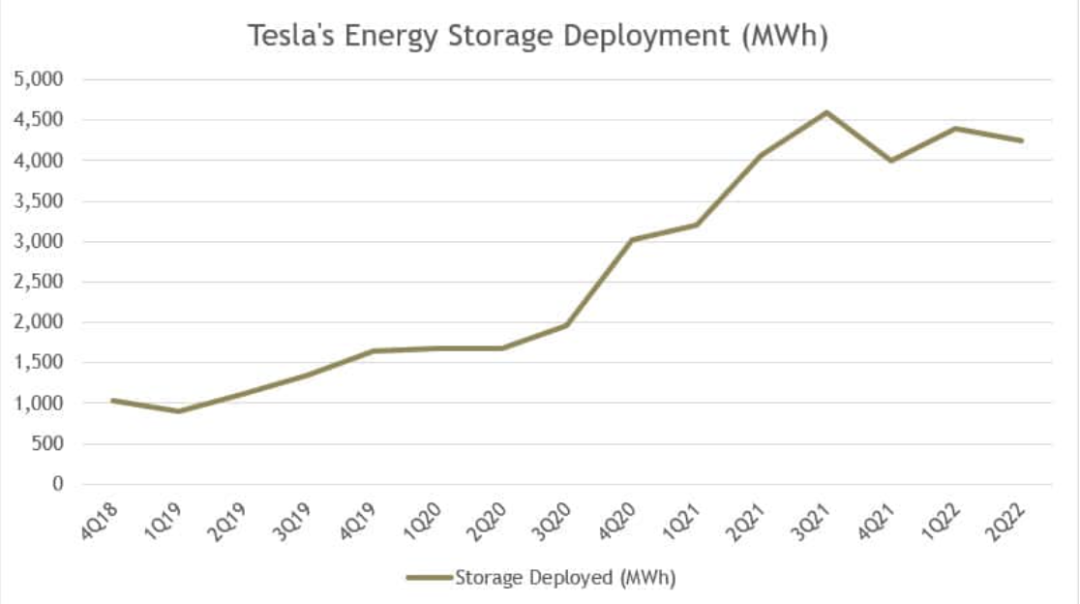

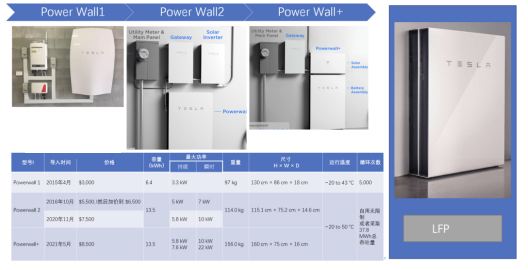

The overall sales of Tesla's Power Wall and Mega Pack are actually very good, and we won't list the specific data in this regard. The chart below shows the development plan of Tesla's ESS system, from which we can draw conclusions.

From Tesla's energy storage planning, this data has been moving upwards. From the product structure, it is mainly divided into Tesla Power Wall, Power Pack and Mega Pack for individuals, individual businesses and energy operating companies.

(Tesla's energy storage deployment)

Tesla's energy storage system fire, a relatively large scale is mainly including the United States, Australia, these two times. In addition a project in South Korea also produced a safety incident.

C: The impact of these safety incidents

SES Power does not believe that these safety incidents will be the main problem that hinders the development of Mega Pack, but it has several impacts.

Chemical system conversion: Tesla's energy storage also began to switch from ternary to lithium iron phosphate, partly due to cost considerations, partly due to life and safety considerations.

Safety system upgrade: from the South Korean energy storage system fire, the safety of the energy storage system has been in front of us, due to the unmanned settings, this issue no personnel accidents, but repeated fires will also further strengthen the pursuit of safety.

Although there are some safety issues, but overall, the energy storage business has now begun to become a new growth engine, is a very important support business unit for lithium batteries. After all, although the energy storage business will grab resources with power batteries in the future, it is also an important hedging business map for battery companies.

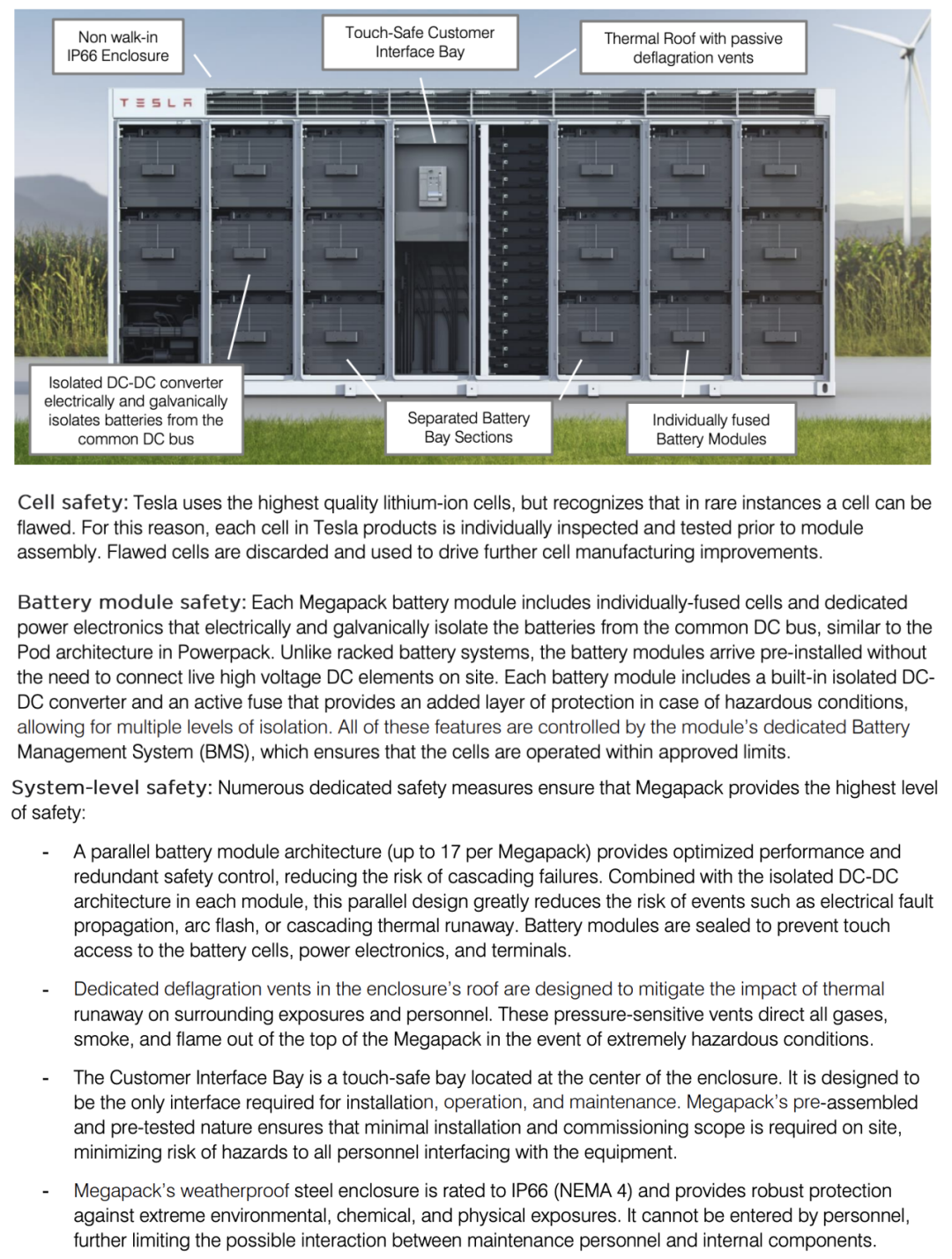

D: Mega Pack's safety design is indeed good

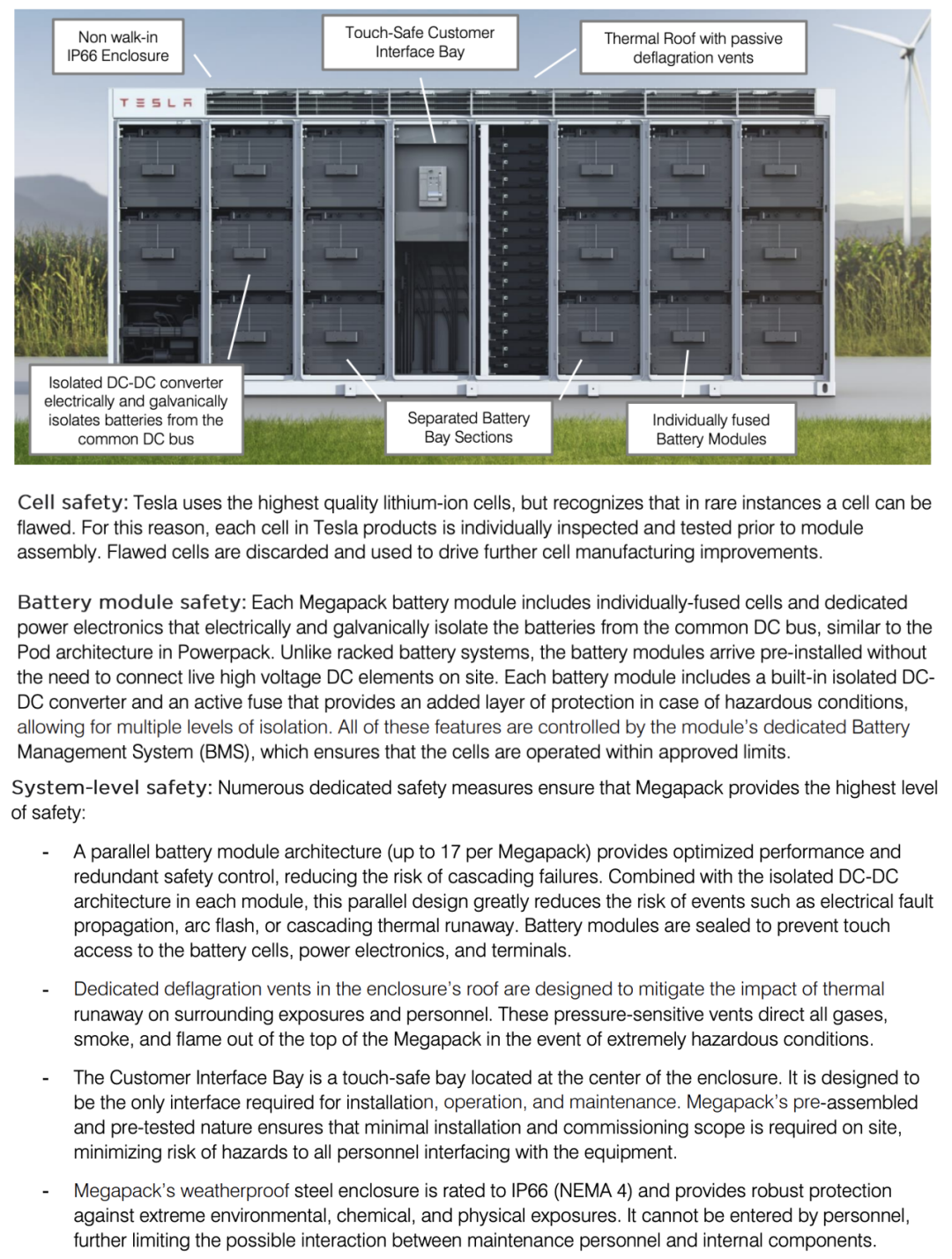

If we look at the safety design of Mega Pack set by Tesla again, it does cover the cell, module and system level.

(MegaPack's safety settings)

E: But why does the Mega Pack produce safety accidents

Energy storage plant accidents can be categorized in broad terms as battery system defects, insufficient redundancy of protection systems for electrical failures, inadequate management of the operating environment, and lack of an integrated management system for the energy storage system.

Battery consideration: This is generally triggered by thermal runaway of the battery, which is the degradation of the energy storage system safety brought about by the factory's defects in the cell manufacturing process and the aging of the battery in both aspects. Although Tesla uses small batteries and disconnect mechanisms, this situation, although the chances are low, but with the increase in deployment, this chance is gradually amplified.

External factors: mainly include current shocks caused by insulation failure, external short circuits and other problems, but also include thermal shocks caused by high temperatures of components other than the battery, as well as the thermal runaway spread process triggered by thermal runaway of a battery.

Operating environment factors: Although the energy storage system is generally a smaller current in operation, but in fact the operating environment management is more complex, if not properly managed will gradually affect the reliability of the battery and the system.

The last is the whole digital operation.

F: Safety iteration of energy storage system

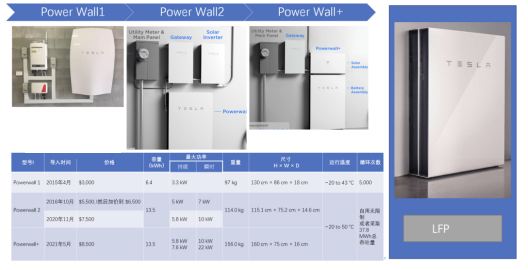

From the safety and life of these two perspectives to consider the energy storage system, Tesla is indeed switching from ternary small cells to lithium iron phosphate large cells: Power walls, Power packs and Mega packs will use lithium iron phosphate.

(With LFP, Mega Pack goes from 2.6 MWh to 3.9 MWh)

(Power Wall will also be iterated to the next generation)

The first generation of energy storage design: built-in module design, using NCA 18650 cells similar to the Model S module placed side-by-side, into the water-cooled tubes to go on both sides of the box, the electronic part including the converter and BMS arranged in the front compartment.

Then evolved a similar program without modules: the system level eliminated the water-cooled program, directly placed the batteries together and then bonded together as a whole, the cells are all made into one large block, through the mode of potting.

And now, the introduction of China's lithium iron phosphate square-case battery program.

(Tesla's design gradually absorb the characteristics of Chinese battery design)

G: From now on, the development of energy storage systems have so many preliminary conclusions

High energy density cells also objectively cannot afford higher abuse, and in China's experience with large energy storage attempts, the use of lithium iron phosphate, which is more tolerant, is a good solution from the perspective of longevity and safety.

In most cases, large cells have a natural advantage over small batteries in energy storage. Energy storage systems require a much smaller multiplier for cells than cars, so going the large-cell route is more favorable from the standpoint of efficiency, cost and characteristics.

3. The introduction of integrated thermal management is very helpful for lithium iron phosphate. Maintain a stable temperature is the key to ensure the life of the energy storage system. In extreme cases, the very rapid cooling of lithium iron phosphate will also delay potential thermal safety incidents.

SES Power is a professional lithium battery energy storage system integrator with nearly two decades of experience, our products have high technical content and extremely high cost performance: UPS high-voltage lithium battery system (up to 860V), 3Kw~20Kw off-grid, grid-connected, islanded lithium battery energy storage system, wall-mounted form of home energy storage system 48V100Ah, 48V200Ah, stacked type energy storage system (single for 51.2V100Ah, support up to 15 stacks) and so on.

If you have any questions about Li-ion home energy storage system, you are welcome to contact SES Power.