Lithium-ion battery energy storage systems have received a lot of attention recently, for the simple reason that they are so hot to sell. But as a consumer, do you know the UL standard for energy storage battery systems? It is related to the safety performance of the product!

As a professional service provider engaged in the R&D and manufacturing of lithium battery energy storage systems, SES Power has more than ten years of experience in the energy storage industry. We mainly use high-quality square aluminum-shell lithium iron phosphate batteries to make our energy storage products, such as Wall-mounted home energy storage system 48V100Ah, 48V200Ah, stacked home energy storage system (5KWh per module, up to 15 modules stacked), lead-acid replacement products (12V100Ah, 12V200Ah, 24V100Ah), UPS high-voltage lithium battery system (up to 860V) , 3Kw~20Kw off-grid, grid-connected, island-type lithium battery energy storage system, backup battery system (standard 19 inches), etc., and often match customers' lithium battery products with solar photovoltaic, inverter, UPS, intelligent charger, etc. Peripheral products.

Therefore, we are very clear about the certification requirements related to energy storage batteries. Let us briefly introduce the changes in the latest version of UL1973, which is the safety standard for battery energy storage systems.

A: What is UL1973?

UL1973 is the safety standard for energy storage battery systems in North America, and is also the recognized standard by ANSI in the United States and SCC in Canada. In addition, this standard is also recognized by other regions, such as CEC in Australia. Products that have obtained this certificate can smoothly enter the North American and Australian markets.

The standard covers all kinds of battery systems used in stationary, photovoltaic, wind energy, backup power supply, communication base station, vehicle auxiliary power supply, LER, etc., but the standard is only a safety standard and does not include performance and reliability evaluation.

IFC (International Fire Code) is an international fire code in the United States, of which section1207ElectricalEnergyStorageSystem involves thermal runaway protection methods and battery system safety requirements in line with UL1973.

NFPA (National Fire Protection Association) Standard is a standard formulated by the American Fire Protection Association, among which NFPA70Article706EnergyStorageSystems also requires thermal runaway protection and safety of battery systems to comply with UL1973.

NFPA70 is equivalent to the US National Electrical Code (NEC). NFPA70 has been adopted by 50 states in the United States and is the benchmark for safe electrical design, installation and inspection to protect people and property from electrical hazards.

NFPA855StandardfortheInstallationofSta-tionaryEnergyStorageSystems is a standard for the installation of stationary energy storage systems formulated by the National Fire Protection Association, of which chapter9Elec-trochemicalEnergyStorageSystems requires battery systems, modules, capacitor systems, modules and thermal runaway protection to comply with UL1973.

UL1973 is also included in the OSHA accreditation standard under the US Department of Labor, see http://www.osha.gov/nationally-rec-ognized-testing-laboratory-program/list-standards for details.

The first edition of the UL1973 standard was released in February 2013 and was recognized by ANSI and SCC. The second edition of the standard was released on February 7, 2018.

According to the information on UL's official website, UL1973 released the third edition on February 25, 2022, and was approved as a national standard by ANSI and SCC at the same time. For details, see https://standardscatalog.ul.com/ProductDetail.aspx?productId=UL1973 .

Comparing the second version and the third version, it is found that there are many new additions and changes.

B: What's changed in the new version of UL1973?

B.1 New Content

B.1.1 Added 7.7 Transformer Requirements

Transformers should be evaluated according to UL1562, UL1310 or equivalent overload conditions and should have suitable insulation for the circuit to which they are connected.

The primary side of the transformer shall be equipped with overcurrent protection, and its dimensions shall comply with the provisions of Article 450 of NFPA70 or Article 26 of C22.1.

B.1.2 Added 7.13 Battery requirements for cascade utilization

Batteries and battery systems using regenerated batteries shall ensure that the regenerated components have passed an acceptable regeneration process in accordance with UL1974.

B.1.3 Added 16 high rate charging test requirements

Evaluate the ability of a battery system to prevent high-rate charging when the battery's maximum charge current is exceeded.

This test shall be performed with a high rate charge with a fully discharged DUT. Unless the overcurrent charge protection device or control has been evaluated for reliability (i.e. functional safety has been evaluated in accordance with 7.9), the overcurrent charge protection or control A single fault condition should exist.

During the test, the current and voltage of the battery shall be measured. The test power supply equipment used to charge the DUT shall be sufficient to supply a current 20% greater than the maximum specified charging rate of the battery.

B.1.4 Added 18 overload discharge test requirements

Evaluate the ability of a battery system to withstand overload discharge conditions.

This test shall be performed on a fully charged DUT with an overload exceeding the specified maximum discharge current of the battery. The positive and negative terminals of the DUT shall be connected to an external discharge device. The fully charged DUT shall then be overloaded at a rate equal to the BMS (secondary protection) rating. Discharge to full discharge at a current of 90% of the current protection value, or reach the protection state.

B.1.5 Added 27EMI electromagnetic anti-interference test requirements

Electrostatic discharge, the DUT shall demonstrate immunity to electrostatic discharge according to the test procedure specified in IEC61000-4-2.

RF electromagnetic fields, the DUT shall demonstrate immunity to RF electromagnetic fields according to the test procedures specified in IEC61000-4-3.

For transients, the DUT shall demonstrate immunity to electrical fast transients/pulses in accordance with the test procedures specified in IEC61000-4-4.

surge, the DUT shall demonstrate immunity to surge in accordance with the test procedures specified in IEC61000-4-5.

RF common mode, the DUT shall demonstrate immunity to RF interference in accordance with the test procedures specified in IEC61000-4-6.

For power frequency, the DUT shall demonstrate immunity to power frequency magnetic fields in accordance with the test procedures specified in IEC61000-4-8.

For operational verification, the manufacturer shall declare the expected performance of all safety functions performed by the active protective device.

The manufacturer shall provide test procedures to verify that each safety function performed by the active protective device is working correctly.

If redundant protection methods are provided for compliant safety functions, each protection method should be evaluated to determine whether it functions as intended.

B.1.6 New test plan for AnnexE lithium-ion battery replacement

This content should be used to evaluate lithium-ion batteries or other lithium batteries, and to add pre-test pretreatment and capacity check tests.

Tests include short circuit test, overcharge test, extrusion test, heavy object impact test, mechanical impact test, vibration test, thermal abuse test, temperature cycle test, low air pressure test, combustion injection test.

B.1.7 Newly added alternative method for AnnexH lead-acid battery and nickel-cadmium battery evaluation

The test includes overcharge test, short circuit test, overdischarge test, temperature test, unbalanced charging test, withstand voltage test, continuity test, hot and cold fault test, static pressure test, heavy impact test, drop test, and compression stress test, structural strength test, salt spray test, external fire test, single cell failure test.

B.1.8 New test method for Annex I mechanical air metal battery

The cell stack test includes vibration test, mechanical shock test, heavy object shock test, high temperature test, short circuit test, forced discharge test, and leakage test.

Mechanical metal-air battery system test includes short circuit test, temperature test, withstand voltage test, continuity test, hot and cold fault test, working voltage test, static pressure test, heavy object impact test, structural strength test, molding stress test, moisture resistance test, Salt spray test, water pressure test, leak test, blockage test, insulation resistance test, leak test.

B.2 Changes

B.2.1 Requirements for a more specific system safety analysis

Compared with the second version, the process of equipment safety analysis is described in more detail: hazard identification, risk analysis and risk assessment.

Guidance documents for the safety analysis process can be referred to

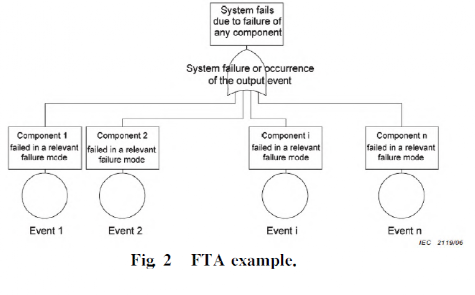

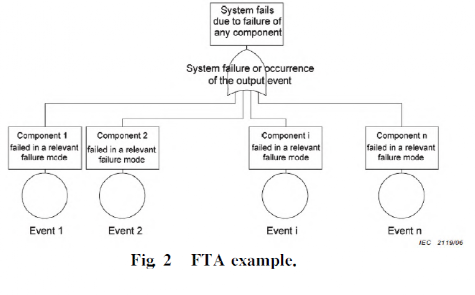

IEC60812 (FMEA), IEC61025 (FTA), MIL-STD-1629A, IEC61508, allparts, as shown below.

FMEA (Failure Mode and Effects Analysis) is failure mode and effect analysis. In functional safety assessment, it is mainly used for safety analysis of simple systems. It does not consider the safety caused by the accumulation of component stress, and only considers the consequences caused by the failure of a single component, so it is A bottom-up approach to analysis.

FTA (FaultTreeAnalysis) is a fault tree analysis method. In functional safety assessment, it is mainly used for safety analysis of complex systems. Starting from the results, analyze the causes of the results, and consider the consequences caused by the accumulation of component stress in the system, so It is a top-down analysis method.

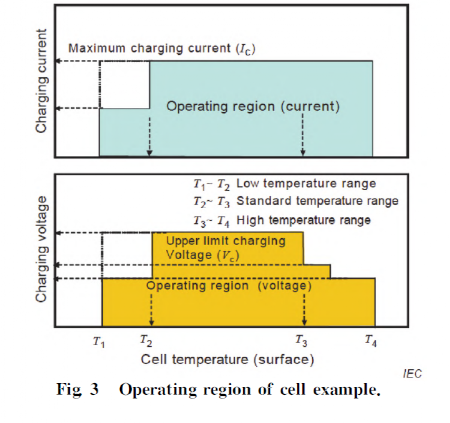

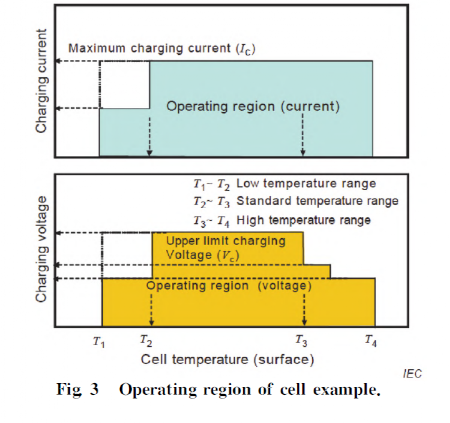

In the safety analysis of the battery system, at least three safety parameter conditions need to be considered: cell overvoltage/undervoltage, cell overtemperature/undertemperature, and battery overcurrent during charging and discharging, as shown in the figure below.

The safety analysis should include a single fault situation in the protection circuit, involving all components and ICs, etc. It is particularly pointed out that the fault simulation of IC (integrated circuits) should consider the following situations:

(1) Short circuit.

①Any two adjacent terminals.

②IC power supply VCC and each terminal (if applicable).

③IC ground VDD and each terminal (if applicable).

All possible combinations of stuck-at faults (single fault) appear on the outputs of multiple IC terminals at once.

B.2.2 More specific protection circuit and control requirements

B.2.2.1 Requirements for critical safety functions in protective circuits

a) redundant passive protection devices, or

b) redundant active protection devices, or

c) satisfy a single fault condition and still be safe; or

d) The protective device meets at least IEC61508SIL2, or

ISO13849PLc, or ISO26262ASILC

Note: Active protection device: a device used to prevent dangerous situations and requires electric power to operate, such as BMS, etc.; passive protection device: a device used to prevent dangerous situations and can detect and operate without electric energy, such as fuses, etc.

B.2.2.2 Requirements for active protection devices in protection circuits

a) Failure Mode and Effects Analysis (FMEA) requirements in Chapter 7 of UL991;

b) Internal fault protection in UL60730-1 or CAN/CSAE60730-1 to ensure functional safety requirements (H.27.1.2); or c) Fault protection in CSAC22.2No.0.8 (chapter 5.5) to ensure functional safety Requirements (Class B requirements) to determine compliance and to determine the testing required for verification slip tolerance.

For hardware circuit architecture design, please refer to the following instructions:

(1) Single-channel (dual protection) architecture (ClassB);

(2) Dual-channel architecture design (ClassB or ClassC).

B.2.2.3 Protection circuit software requirements

Level 1 software requirements of UL1998;

b) CSAC22.2No.0.8 software class B requirements; or c) UL60730-1 (clause H.11.12) or CAN/CSA

Control requirements for software used in E60730-1 (software level B requirements).

B.2.2.4 Protection circuit electromagnetic interference EMI requirements

Protective circuits and software controls for safety should be evaluated and tested in accordance with 27 Electromagnetic Interference EMI to verify electromagnetic immunity.

C: The impact of these changes

Compared with the second edition of UL1973, the third edition adds some structural requirements, electrical test requirements, electromagnetic compatibility EMI requirements, test plans for the replacement of secondary lithium batteries, alternative methods for evaluation of lead-acid batteries and nickel-cadmium batteries, and mechanical compatibility. Test methods for rechargeable air metal batteries, etc.

In general, the content is richer, the field of use is clearer, the functional safety assessment is more detailed, and the safety assessment is more complete.

If it is a product that has been certified by the UL1973 second edition standard before, some structural inspections and difference tests need to be supplemented, and even functional safety level evaluation is required to update to the third edition.

If it is a new product that is planned to be sold in the U.S. market, it is necessary to take into account the requirements of the third edition of the standard in the product design stage, so as to avoid re-rectification or update later.

D: SES Power makes the final summary for you

UL1973 is recognized by standard systems such as IFC, NFPA70, NFPA855, OSHA and SCC, which shows its applicability and importance.

Then, SES Power summarizes the new contents and changes of the third edition of UL1973 for you, and elaborates the requirements of functional safety. Finally, it gives a suggested hardware architecture solution as a reference.

As a professional manufacturer of customized lithium-ion battery energy storage systems, SES Power will take the latest changes of the third edition of UL1973 as the guiding direction of research and development, grasp the market trend, and design and manufacture high-end energy storage batteries for a wide range of customers. Quality performance product.