Lithium iron phosphate battery VS ternary lithium battery, SES Power

explains the differences between the two branches of lithium battery in

detail

In recent years, lithium-ion batteries have been widely used as the main

force of secondary rechargeable batteries. With the impact of global energy

demand, unstable petrochemical energy supply, and fluctuations in the

development of new energy, lithium-ion batteries have become increasingly

important.

Lithium iron phosphate and ternary lithium batteries are the two major

technical routes in lithium-ion batteries, and their battle has never stopped.

Lithium iron phosphate batteries, which can perfectly replace lead-acid

batteries, are the younger generation. In addition to capturing the market share

of lead-acid batteries, nickel-metal hydride batteries, and nickel-chromium

batteries, they are also accelerating the market for ternary lithium

batteries.

As SES Power with 20 years of rich experience in the customized lithium

battery industry, our products are mainly focused on energy storage system

integration and lithium batteries in special scenarios, such as fully

intelligent lead-acid replacement with Bluetooth or RS485 communication.

Products (lithium iron phosphate 12V100Ah, 12V200Ah), CCA2000A lithium iron

phosphate high-current starting lithium battery (direct replacement for

automotive lead-acid starting batteries), UPS high-voltage lithium battery

system (up to 860V), 3Kw~20Kw off-grid, grid-connected, island type Lithium

battery energy storage system, base station communication backup battery system

(standard 19 inches), full set of photovoltaic energy storage components, normal

charging and discharging lithium batteries under -40 degrees Celsius

environment, etc. We are very familiar with lithium iron phosphate batteries and

ternary lithium batteries. Let our senior engineers analyze the two major

branches of lithium batteries for you.

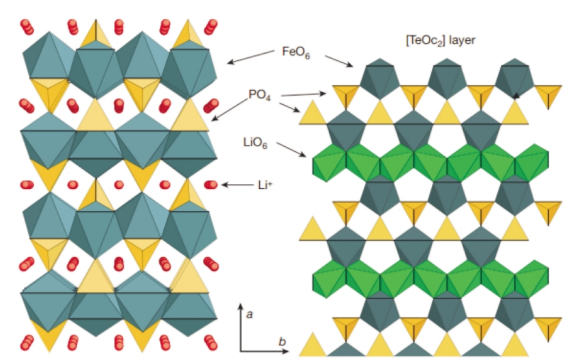

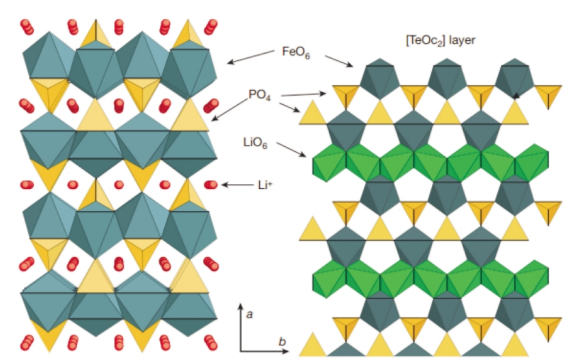

A: Lithium iron phosphate material and battery

The LiFePO4 with a three-dimensional spatial network olivine structure

forms a one-dimensional Li+ transport channel, which limits the diffusion of

Li+; at the same time, the octahedral FeO6 is connected at the top, making its

electronic conductivity low, and the polarization is relatively high during

high-rate discharge. big.

The charging and discharging process of LiFePO4 material mainly transforms

between LiFePO4 and FePO4 phases, and the volume change rate is small, which

makes the material extremely stable, so the safety and stability of lithium iron

phosphate materials and batteries are beyond doubt.

(Structural model diagram of lithium iron phosphate material)

Lithium iron phosphate batteries mainly have the following

characteristics:

(1) The cycle performance of lithium iron phosphate batteries is excellent,

and the cycle life of energy-type batteries can be as long as 3,000 to 4,000

times, and models with cycles that can even reach tens of thousands of times can

be manufactured according to customer needs;

(2) The lithium iron phosphate battery has excellent safety performance, it

can maintain a relatively stable structure even at high temperature, and even

when the battery is deformed and damaged, there will be no safety accidents such

as smoke and fire.

Lithium iron phosphate raw material resources are relatively abundant,

which greatly reduces the cost of materials and batteries. That is, in the

future, the price reduction ratio of lithium iron phosphate batteries will be

greater than that of ternary lithium batteries.

At the same time, since iron and phosphorus elements are environmentally

friendly, lithium iron phosphate materials and batteries do not pollute the

environment. This is also one of the reasons why lithium iron phosphate

batteries can completely replace lead-acid batteries.

The structural properties of LiFePO4 material determine that the material

has low ionic and electronic conductivity, and as the temperature decreases,

both the electron transfer resistance and the charge transfer resistance

increase rapidly, resulting in poor low temperature performance of the battery.

Of course, this problem has been overcome by SES Power, our 26650 lithium iron

phosphate battery with a capacity of up to 3400mah, it can discharge at a rate

of 3C at -40 degrees Celsius with an efficiency of 90%, and can be discharged at

-30 degrees Celsius at 3C Rate charging, and life is not affected, so it is

widely used in polar environments, such as electric snow sleds, snow electric

motorcycles, Antarctic and Arctic inspection instruments, outdoor monitoring

equipment in extremely cold environments, etc.

B: Ternary materials and batteries

Li(NixCoyMn1-x-y )O2 material has attracted great attention of researchers

since it was first reported, for the simple reason that it can reduce the amount

of Co used. This can reduce the cost pressure brought about by price

increases.

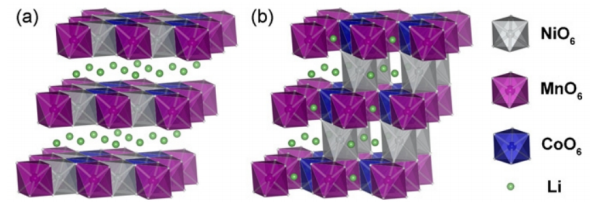

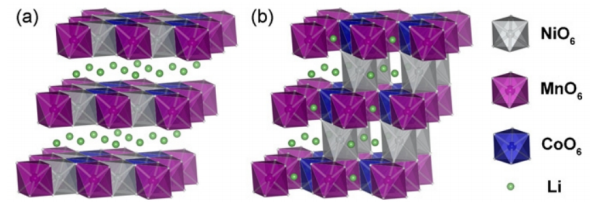

Li(NixCoyMn1-x-y )O2 has structural similarities with LiCoO2. Taking the

NCM111 ternary material as an example, Li+ is located at the 3a position in the

structure, Ni, Mn, and Co are randomly distributed at the 3b position, and

lattice oxygen occupies the 6c position. The transition metal layer structure is

composed of Ni, Mn, Co, and is surrounded by 6 lattice oxygens to form a MO6

(M=Ni, Co or Mn) octahedral structure, and lithium ions are inserted between the

MO6 layers. During the charging and discharging process, lithium ions are

deintercalated in the interlayer structure of MO6, and the electric pairs

participating in the electrochemical reaction are Ni2+/Ni3+, Ni3+/Ni4+ and

Co3+/Co4+, respectively, while Mn is electrochemically inert and does not

contribute to electrochemical reactions. capacity.

(Structure diagram of ternary material without Li/Ni shuffling (a) and with

Li/Ni shuffling (b))

According to the proportion of Ni content, ternary materials and batteries

can be divided into conventional type and high nickel type. With the increase of

Ni content, the deintercalable lithium increases, and the material capacity and

battery energy density increase. Therefore, high-nickel ternary materials and

batteries are the current research hotspot and full of challenges.

(1) Since the radius of Ni2+ is very close to the radius of Li+, with the

increase of Ni content, the probability of Li/Ni mixing in high-nickel ternary

materials increases sharply during high-temperature sintering preparation, and

the lithium deintercalation into the MO6 layer is more difficult. It hinders the

Li+ transport ability, resulting in lower specific capacity and lower cycle

performance, which is difficult to reverse.

(2) With the increase of Ni content, the proportion of Ni3+ in the material

also increases, and Ni3+ is very unstable, and it is very easy to react with

moisture and CO2 in the air to generate surface residual alkali when exposed to

air, resulting in the capacity of ternary materials. and cycle performance loss.

In addition, too much residual alkali on the surface will cause serious gas

production in the ternary battery, affecting its cycle performance and safety

performance.

(3) The high-valent Ni element also has high catalytic activity and

oxidizing property, which leads to the decomposition of the electrolyte and also

causes the battery to produce gas. In order to solve the above problems,

customization of precursors, individualization of sintering process, ion doping,

surface coating modification, wet processing and production environment control

have become common choices for ternary material manufacturers.

For the ternary battery, its performance characteristics mainly include

high material mass specific capacity, mass and volume specific energy, good rate

performance and low temperature performance, but due to the stable structure and

scarcity of nickel and cobalt resources, its cycle Better performance, general

safety performance, and higher cost.

C: Detailed comparison and analysis of two materials and batteries

c.1 Energy density

Compared with lithium iron phosphate materials, ternary materials have

higher discharge specific capacity and higher average voltage, so the mass

specific energy of ternary batteries is generally higher than that of lithium

iron phosphate. In addition, due to the low true density, small particle size

and carbon coating of the lithium iron phosphate material, the compacted density

of the pole piece is about 2.3-2.4 g/cm3, while the compacted density of the

ternary pole piece can reach 3.3 ~3.5 g/cm3, so the volume specific energy of

ternary materials and batteries is also much higher than that of lithium iron

phosphate.

c.2 Security

The main structure of the lithium iron phosphate material is PO4, and the

bond energy is much higher than the M-O bond energy of the ternary material MO6

octahedron. The thermal decomposition temperature of the fully charged lithium

iron phosphate material is about 700 °C, while the thermal decomposition

temperature of the corresponding ternary material is 200 to 300 °C, so the

lithium iron phosphate material is safer.

From a battery perspective, lithium iron phosphate batteries can pass all

safety tests, while ternary batteries cannot easily pass tests such as

acupuncture and overcharge, and need to be improved from structural parts and

battery design.

c.3 Power performance

The activation energy of Li+ of the lithium iron phosphate material is only

0.3-0.5 eV, resulting in a Li+ diffusion coefficient of the order of 10-15-10-12

cm2/s. The extremely low electronic conductivity and lithium-ion diffusion

coefficient lead to the poor power performance of LFPs. The Li+ diffusion

coefficient of the ternary material is about 10-12 ~ 10-10 cm2/s, and the

electronic conductivity is high, so the ternary battery has better power

performance.

c.4 Temperature suitability

Affected by the low electronic conductivity and ionic conductivity of the

lithium iron phosphate material, the low temperature performance of the lithium

iron phosphate battery is poor. Compared with normal temperature, the capacity

retention rate of lithium iron phosphate battery at -20 ℃ discharge is only

about 60%, while the ternary battery of the same system can reach more than

70%.

Of course, this problem has been solved by SES Power.

c.5 Cost and Environmental Factors

Ternary materials contain rare metals such as Ni and Co, and the cost is

higher than that of lithium iron phosphate. With the improvement of materials

and battery technology, the cost of ternary and lithium iron phosphate batteries

has dropped significantly. At present, the market price of ternary batteries is

higher than that of lithium iron phosphate batteries.

At the same time, compared with the environmentally friendly Fe and P

elements, the Ni and Co elements in the ternary materials and batteries are more

polluting to the environment. Combined with the above factors, the demand for

environmental control and waste recycling of ternary materials and batteries is

more urgent.