Tesla fell into a "trap"? SES Power deeply analyzes the plight of 4680

lithium battery for you

"We will have mass production of 4680 cells by the end of the year, but

it's hard to predict because there's a lot of new technology in there." At Tesla

Inc's 2022 shareholder meeting in early August, the company's CEO Elon Musk

said, "We are confident that we will have high production rates, but we may not

be able to achieve high production until the end of this year."

But when he said this, Musk's voice was not very confident. Musk, who was

dressed in black, held the microphone, his face was a little dignified, and his

eyes fell to the ground twice. Compared with the high-spiritedness two years

ago, it seems to be different: in September 2020, the high-spirited Musk

launched the "epoch-making" Tesla 4680 battery. He said the battery will achieve

a planned production capacity of 100GWh in 2022, supporting at least 1 million

electric vehicles.

However, the reality is far from what Musk expected. As a manufacturer with

nearly 20 years of experience in customizing lithium-ion batteries, SES Power

focuses on the integration of lithium-ion battery energy storage systems, such

as fully intelligent lead-acid replacement products with Bluetooth or RS485

communication (Lithium iron phosphate 12V100Ah, 12V200Ah), high current (2000A)

starting lithium battery, UPS high voltage lithium battery system (up to 860V),

3Kw~20Kw off-grid, grid-connected, island-type lithium battery energy storage

system, base station communication backup battery system ( Standard 19 inches),

a full set of photovoltaic energy storage modules (PV+Battery+Inverter), etc.,

but we are full of respect for Musk and marvel at his ability to turn seemingly

impossible predictions into reality, but this time we did It is believed that

Tesla's performance on the 4680 lithium battery model is far from our

expectations.

To date, Tesla has only started small-volume production of 4680 cells at

its Kato Road plant near Fremont, California, and its Austin Gigafactory, Texas.

One of Tesla's suppliers, the battery manufacturer Panasonic Corporation of

Japan, made it clear that the 4680 battery is still in the testing stage, and

mass production will not start until April 2023.

Not only has Panasonic delayed the mass production plan, but CATL, one of

the rumored Chinese partners of the 4680 battery, still has vague plans. CATL

recently stated that there is no information about the 4680 battery to be

disclosed.

Below, SES Power will sort out why some peers think Tesla has fallen into

the "trap" for you.

A: What happened to the 4680 battery?

The full name of the 4680 cylindrical battery is the 4680 specification

electrodeless (all-pole) cylindrical battery. 4680 refers to the size of the

battery - 46 refers to a cylindrical battery with a diameter of 46mm, and 80

refers to a battery with a height of 80mm.

According to the data released by Tesla, compared with the traditional 2170

cylindrical battery, the energy of the 4680 battery will be 5 times that of the

former, the cruising range of the vehicle will be increased by 16%, and the

power will be increased by 6 times. Improvements, the net increase in range will

be as high as 56%, and production costs can be saved by 54%.

The Kato Road plant near Fremont, California, was originally a small pilot

plant, but now it has become the main production base for 4680 batteries. In

April of this year, the first Tesla Model Y loaded with 4680 battery packs was

assembled and delivered at the Texas Gigafactory, and the batteries used were

also produced by the factory.

The 4680 battery production line at the Texas Gigafactory is expected to be

put into production only in small quantities from the second quarter of this

year.

At present, there is no published battery output and capacity data from the

Kato Road factory. However, from a document leaked from the Kato Road factory in

the first half of this year, we can get a glimpse of the production efficiency

of 4680 batteries at the factory. According to the autoevolution website, the

leaked document shows that the factory had 14 machines running that day, of

which 13 produced "good" quality batteries with a pass rate of over 90%, with

one exception, machine 212 due to training Employees from the Gigafactory in

Texas produced 82 percent of the "bad" batteries. According to statistics, the

overall production pass rate of the battery that day was 92%.

In terms of output, the Kato Road factory produced a total of 6,250 4680

batteries that day, and a Tesla Model Y currently assembled at the Texas

Gigafactory requires about 690 4680 batteries. According to the production of

the Kato Road plant that day, the amount of batteries produced per day supports

about 10 Model Ys, which is far below the target output of the Texas

Gigafactory.

Production efficiency and capacity are still slowly climbing. Production

efficiency is expected to increase at the Kato Road plant in August, to produce

220 battery packs per week, while the Gigafactory in Texas will produce 183

battery packs per week. However, Tesla won't reach weekly production of 5,000

4680 battery packs until May 2023.

According to a report on the insideevs website, in late July, Andrew

Baglino, Tesla’s senior vice president of powertrain and energy engineering,

said on an investor conference call, “Tesla wants a battery factory in Austin.

By the end of 2022, it can surpass the weekly production of the Kato Road

factory, which is expected to produce more than 1,000 battery packs per week by

the end of the year.”

According to Tesla's plan, the annual production capacity of 4680 batteries

at the Kato Road factory will reach 10GWh, which can roughly meet the needs of

150,000 electric vehicles; the production capacity of the Texas Gigafactory is

expected to be built within the year to 60GWh. At present, Tesla's own 4680

battery capacity under construction also includes Tesla's Berlin plant, which is

expected to reach 20GWh after completion, but the production capacity will not

be released until the fourth quarter of 2022.

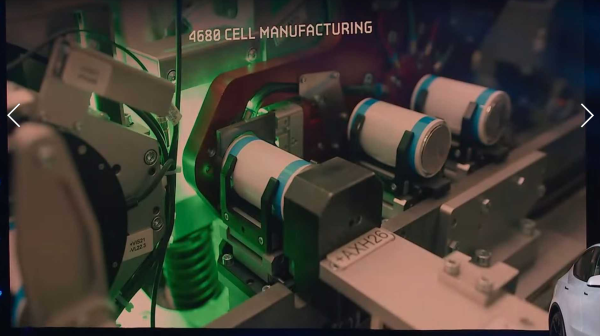

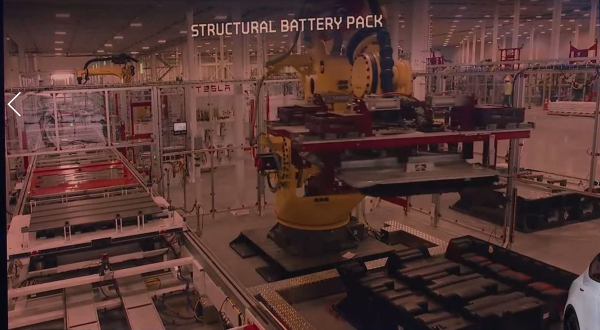

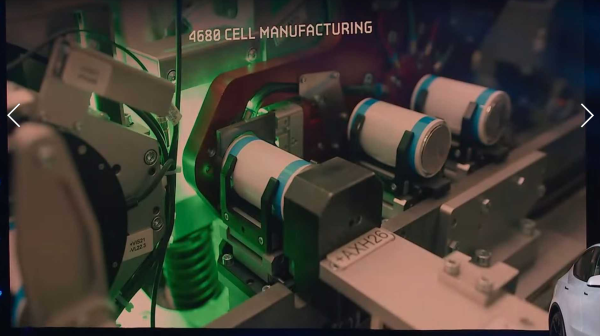

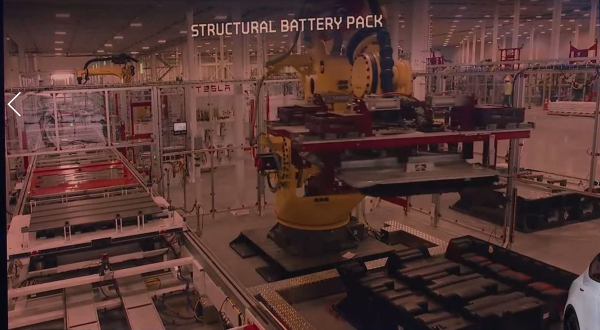

(4680 battery production line at Tesla's Texas Gigafactory)

In terms of partners, Japan's Panasonic and South Korea's LG New Energy

have both expressed their capacity plans for 4680 batteries. However, Panasonic

has made it clear that the 4680 battery is still in the testing stage, and the

company will gradually expand its production capacity to prepare for full

promotion.

South Korea's LG New Energy announced in June that it would invest 580

billion won (about 3.8 billion yuan) to build a new 4680 battery production line

at the second factory in Wuchang, Chungbuk, South Korea, to supply Tesla with a

production capacity of 9 GWh, but the time to put into mass production is also

in the second half of next year.

Kazuo Tadanobu, CEO of Panasonic's energy division, previously said in an

interview that while the 4680 battery can reduce the cost of electric vehicles

while maintaining safety and improving performance, it's not just about making a

bigger battery . Working on this project is not as easy as some might think. He

said the battery development process "requires enormous endurance" and that

changing the shape of the battery requires "considerable brain circuits."

B: What are the difficulties in mass production of 4680 batteries?

In theory, the technical maturity of cylindrical batteries is the highest,

otherwise 18650 lithium batteries will not become the overlord in the field of

secondary rechargeable lithium-ion batteries.

For electric vehicles, the capacity of 18650 cells is small (generally no

more than 3.5Ah), the number of cells required is large (6000-7000 cells), and

the battery management is difficult. Therefore, Tesla and Panasonic launched the

21700 cylindrical lithium battery product: a larger volume can accommodate more

electrode materials and save space for structural parts. Although the 2170 has a

certain improvement compared to the 18650, there is no qualitative leap, and it

can only be regarded as an enlarged version of the 18650 lithium battery.

In SES Power's view, compared with the 18650 and 21700 batteries, the mass

production of the 4680 battery is very difficult because it must be a fusion of

multiple innovative technologies.

First of all, the precision requirements of the battery winding machine are

very high, and the main difficulty lies in the welding process of the tabs:

Tesla is most proud of the 4680 battery, which is the electrodeless (full tab)

technology of the battery. The tab of the battery cell refers to the metal

conductor that leads the positive and negative electrodes from the battery cell,

and is the key path when the battery is charged and discharged. The material and

size of the tabs will affect the internal resistance and overcurrent capability

of the cell.

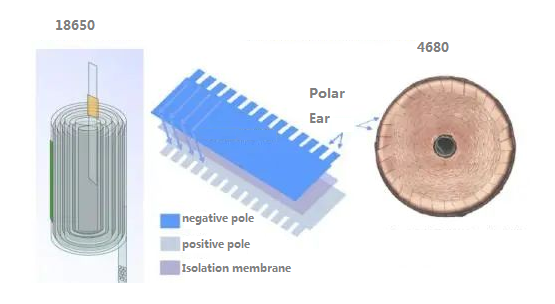

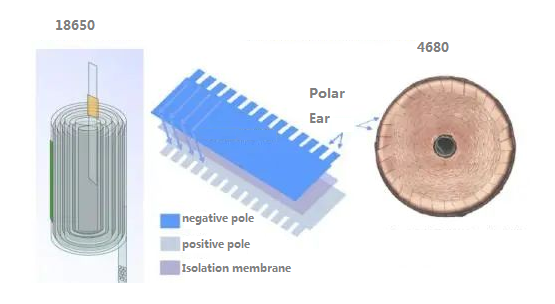

The traditional 18650 cylindrical product usually has only two tabs, which

are connected to the positive and negative poles respectively due to their small

capacity and low output current (as shown on the left side of the figure below).

The 4680 cylinder uses an all-tab design, and the positive aluminum foil and

negative copper foil exposed from both ends of the winding body are rolled into

one end face as a tab (as shown on the right side of the figure below). The

number of tabs increases, and the current paths also increase. At the same time,

the distance between the tabs can also be shortened, thereby greatly reducing

the internal resistance of the cell, effectively reducing the heat generation of

the cell, and improving the energy of the fast charge and discharge of the

cell.

When the electrolyte is injected, since both ends are closed by the tabs,

continuous injection production cannot be performed, and it is difficult for the

electrolyte to enter the interior of the cell. These will be difficult problems

to improve battery productivity.

Second, the space utilization of the battery is low. Under the same

chemical system, the space utilization of large cylindrical cells is much lower

than that of square cells. If a ternary material is used, the square battery can

use ordinary nickel-cobalt-manganese (532) or nickel-cobalt-manganese (622)

material, but the 4680 battery must use high nickel material to have similar

power, although it has a higher energy density, But it also means that the risk

of thermal runaway is high, which must be paid attention to at the system

protection level.

Third, heat dissipation is difficult. Most of the heat generated by the

battery comes from the electrochemistry itself. The cylindrical battery

generally dissipates the fastest axial heat and the slowest lateral heat

dissipation. The large volume of the 4680 battery makes this feature more

obvious. Under 800V high-voltage charging, the battery will accumulate a lot of

heat in a short period of time, and the side heat dissipation speed will be

slower. In the long run, it will have a bigger impact on the life of the

battery. The way Tesla uses is to add a water-cooling plate on the top to

achieve the effect of two-way cooling on the side and the top. It is currently

unknown how the effect will be.

Fourth, the negative electrode material. The anode of the 4680 battery is

planned to use silicon carbide in order to improve energy density, but it has

some disadvantages. For example, the cost is high; there are many side

reactions, large swelling, low efficiency of one charge and discharge, which

affects the quality of the battery; the battery is easily affected by the volume

change of silicon; lithium ions are consumed in large quantities, which may

reduce the cycle characteristics and battery capacity.

C: Maybe, this is not a "trap", it just needs a little patience

Tesla had to continue to rely on the 21700 cells produced at its

Gigafactory in Texas to meet demand for the Model Y due to production hurdles

for 4680 cells.

"We have enough 21700 batteries to meet the rest of the new car needs this

year. Tesla doesn't need to rely on 4680 batteries this year, but 4680 batteries

will play a very important role next year." At the shareholder meeting, Musk

said. The mass production schedule of the 4680 battery may not affect Tesla's

goal of producing 1.5 million new cars this year, but 2023 will be

different.

Because it is critical to the smooth mass production of Tesla's electric

pickup, the Cybertruck. When launching the Cybertruck, Tesla promised a series

of excellent performances, and the 4680 battery was necessary to deliver on

those promises. Some industry insiders believe that the mass production of

Tesla's 4680 is far behind the original plan, which directly affects the mass

production of Cybertruck, electric semi-trailer truck Semi and other models.

However, the good news is not without. The 4680 cells that have been

produced still show advantages in terms of energy density and fast charging

performance.

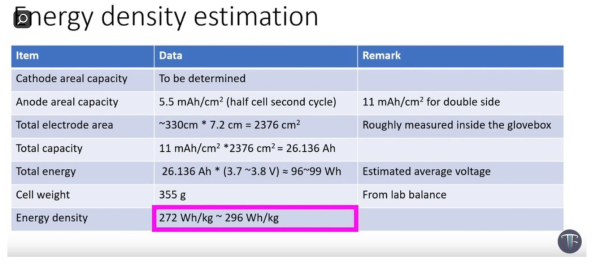

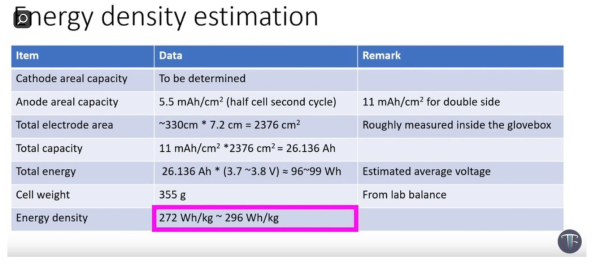

According to the dismantling test report of Tesla 4680 battery by The

Limiting Factor, a 4680 battery weighs about 355g and has a total capacity of

about 26.136Ah. According to the rated voltage of 3.7-3.8V, the rated energy is

about 96-99Wh. Simple calculation, the current energy density of 4680 cells is

about 272-296Wh/kg, and according to Tesla's iterative plan, the energy density

of the second generation 4680 battery will reach 305 Wh/kg, and the third

generation will reach 333 Wh/kg.

For comparison, the system energy density of BYD's first-generation blade

battery is 140Wh/kg, and it is expected to be greater than 180Wh/kg in 2025. The

system energy density of the latest Kirin battery (ternary high nickel system)

of CATL is 255Wh/kg, and it can achieve 160Wh/kg in the lithium iron phosphate

system. In terms of energy density, 4680 batteries have certain advantages.

In addition, in April of this year, Tesla delivered a Model Y equipped with

4680 batteries produced at the Texas Gigafactory. The first customers to get a

chance to drive the new model were pre-orders in the Austin area, and many

provided a lot of information on mileage testing and charging testing of the

4680 battery.

In one test, the user charged the battery on a V3 Supercharger in Texas to

9% in 3 minutes, 9% to 50% in 12 minutes, 80% in 34 minutes, and 40% in 40

minutes. 90%, 97% in 50 minutes. However, the new battery can't sustain the

250kW top charge for very long, and the top value of the speed drops faster than

the 2170 battery.

"In any case, it is still too early to make a proper evaluation of the 4680

battery." An industry insider commented.

Andrew Bagrino, Tesla's senior vice president of powertrain and energy

engineering, stressed that Tesla's challenge with the 4680 battery is an

engineering problem, not a scientific one. This means that with enough

optimization work, Tesla may be able to get out of the 4680 battery mass

production dilemma.