SES Power is often asked a question by customers: the capacity of a single

lithium-ion battery is 100Ah, why is it lower than the theoretical value after

connecting in series and parallel?

As a manufacturer specializing in the research and development and

manufacture of lithium-ion batteries, we have nearly 20 years of experience in

the lithium-ion industry. Our products have high technical content, such as

fully intelligent lead-acid replacement products (12V100Ah, 12V200Ah), large

Current (2000A) start-up lithium battery, UPS high voltage lithium battery

system (up to 860V), 3Kw~20Kw off-grid lithium battery energy storage system,

base station communication backup battery system (standard 19 inches), etc. We

naturally compare this issue. The situation, frankly, cannot be solved in a

simple sentence. To answer this question seriously, we must be required to have

knowledge of all aspects of lithium batteries, because this knowledge is the

foundation.

A: What is a lithium battery pack, and what should be the focus on

batteries?

Lithium-ion batteries have the advantages of large capacity, high specific

energy, good cycle life, and no memory effect, and are naturally widely used.

Lithium battery PACK is also developing in the direction of large capacity, high

voltage, long life and high safety.

Lithium-ion battery PACK is a product that tests the electrical performance

of the cells after screening, grouping, packaging and assembly to determine

whether the capacity and pressure difference are qualified. If you don't pay

attention to the following three aspects, then the question at the beginning of

the article will arise: why the capacity after the pack cannot reach the

theoretical value obtained by the calculation of the single cell.

The consistency of the cells needs special consideration in the battery

pack. Only with good capacity, state of charge, internal resistance, and

self-discharge consistency can the capacity of the battery pack be exerted and

released. Poor consistency will seriously affect the overall performance of the

battery pack, and even lead to overcharge or overdischarge, resulting in safety

hazards. A good combination scheme is an effective way to improve the

consistency of monomers.

Temperature is also an important point: Lithium-ion batteries are

constrained by ambient temperature, and either too high or too low temperatures

will have an impact on battery capacity. If the battery works under high

temperature conditions for a long time, its cycle life may be affected. If the

temperature is too low, the capacity will be difficult to exert.

The last important point is that the real use link is to comply with the

discharge rate curve in the battery specification. If the rate is too small, the

charging and discharging speed will be slow, which will affect the efficiency;

if the rate is too large, the capacity will be reduced due to the polarization

effect and thermal effect of the battery.

B. How to do a good job in the matching of cells to improve

consistency?

A good configuration can not only improve the utilization rate of the

cells, but also control the consistency of the cells, which is the basis for

achieving good discharge capacity and cycle stability in the discharge of the

battery pack. This is the point!

Poorly matched battery packs have increased dispersion, which in turn

impairs battery pack cycle performance and usable capacity. Dynamic grouping is

a relatively good method.

The dynamic characteristic matching method mainly realizes the matching

function according to the charge and discharge curve of the battery. The

specific implementation steps are to first extract the feature points on the

curve to form a feature vector. According to the distance between the feature

vectors between each curve, For the matching index, the classification of the

curve is realized by selecting an appropriate algorithm, and then the battery

matching process is completed.

This matching method takes into account the performance changes of the

battery during operation. On this basis, other suitable parameters are selected

for battery matching, and batteries with more consistent performance can be

sorted.

C. The charging method will affect the capacity of the lithium battery

pack

Appropriate charging methods and processes have a significant impact on

battery capacity. If the charging depth is shallow, the discharge capacity will

be reduced accordingly. If overcharged, it will affect the chemical active

substances of the battery and cause irreversible damage, reducing the capacity

and life of the battery.

Therefore, it is necessary to select an appropriate charging rate, upper

limit voltage and constant voltage cut-off current to ensure that the charging

efficiency and safety and stability are optimized while the charging capacity is

achieved. At present, power lithium-ion batteries mostly use constant

current-constant voltage charging mode.

Balanced charging is a way to solve the difference between cells. It

provides the possibility to achieve a similar initial SOC platform for each cell

discharge, and finally achieves an improvement in discharge capacity and

discharge efficiency (discharge capacity/matching capacity). The equalization

method in charging refers to the equalization of the power battery during the

charging process. Generally, the equalization starts when the voltage of the

battery pack reaches or exceeds the set voltage, and the overcharging is

prevented by reducing the charging current.

D. The discharge rate will directly affect the capacity performance of the

lithium battery pack

The discharge rate is an important indicator for lithium-ion batteries.

High-rate discharge is a challenge for positive and negative electrode materials

and electrolytes. For lithium iron phosphate, its structure is stable, the

strain during charging and discharging is small, and it has the basic conditions

for high current discharge, but the disadvantage is that the conductivity of

lithium iron phosphate is poor. The diffusion rate of lithium ions in the

electrolyte is the main factor affecting the discharge rate of the battery, and

the diffusion of ions in the battery is closely related to the structure of the

battery and the concentration of the electrolyte.

Therefore, different discharge rates lead to different discharge times and

discharge voltage platforms of the batteries, which in turn lead to different

discharge capacities, which are especially obvious for parallel battery packs.

Therefore, it is necessary to select an appropriate discharge rate. The

relationship between discharge capacity and discharge rate (current) can be

described by the Peukert equation:

In the formula: “I” is the discharge current; “n” is the Peukert constant,

which is related to the structure of the battery, and its value is 1.15 to 1.42;

“K” is a constant, which is a constant related to the amount of active material

in the battery.

The usable capacity of the battery decreases as the discharge current

increases. This is also a very important point. SES Power will indicate the

definition of standard charging and discharging states and processes in the

product specification. Only the capacity data obtained after cycling under these

conditions is the real capacity of the lithium battery pack. For example, we

stipulate that the discharge calculation capacity is performed at a current of

0.5C, and the customer uses a 1C current, which will inevitably affect the final

capacity performance.

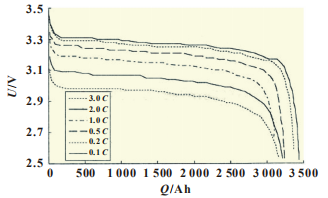

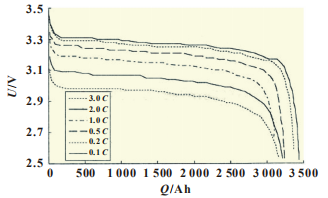

We can study the effect of the lower discharge rate on the capacity of the

lithium iron phosphate battery: a group of single cells of the same type with

good initial consistency are charged to 3.65V at a current of 1C, and then

charged at 0.1, 0.2, 0.5, 1 , 2, 3C discharge rate discharge to 2.5V, record the

relationship between voltage and discharge capacity, the experimental results

show that the discharge capacity of 1, 2C is 97.8% and 96.5% of the discharge

capacity of C/3, respectively, the released energy They are 97.2% and 94.3% of

the energy released by C/3, respectively. It can be seen that with the increase

of the discharge current, the released capacity and released energy of the

lithium-ion battery are significantly reduced.

(Voltage-discharge capacity curves for different discharge rates)

E. Temperature is a huge factor affecting the discharge capacity of lithium

batteries

Temperature mainly affects the activity and electrolyte performance of the

electrode material inside the battery. Too high and too low temperature have a

greater impact on the capacity of the battery.

For example, a conventional lithium battery can release 100% of its

capacity at 25 degrees Celsius, but at 0 degrees Celsius, it can only release

about 80% of its capacity.

At low temperature, the activity of the battery is significantly reduced,

the ability to intercalate and extract lithium decreases, the internal

resistance and polarization voltage of the battery increase, the actual usable

capacity decreases, the battery discharge capacity decreases, the discharge

platform is low, and the battery is more likely to reach the discharge cut-off

voltage, which is expressed as The available capacity of the battery decreases,

and the energy utilization efficiency of the battery decreases.

When the temperature rises, the extraction and insertion of lithium ions

between the positive and negative electrodes becomes active, so that the

internal resistance of the battery decreases, and the internal resistance

stabilization time becomes longer, which increases the amount of electron

mobility in the external circuit and the capacity is more effective. play.

However, if the battery works in a high temperature environment for a long time,

the stability of the positive lattice structure will be deteriorated, the safety

of the battery will be reduced, and the life of the battery will be

significantly shortened.

Both high temperature and low temperature will affect the performance and

service life of the lithium iron phosphate battery. In the actual working

process, methods such as increasing battery thermal management should be used to

ensure that the battery works under suitable temperature conditions. In the

battery pack PACK test, a constant temperature test room of 25°C can be

established.

Summarize:

A good battery matching method is the premise to improve the discharge

performance and level of the battery pack; the charging method is recommended to

use the balanced charging method to ensure that the SOC platforms of each cell

are similar before discharge; it is necessary to select the appropriate

discharge rate; the environment has a greater impact on battery testing , it is

necessary to control the temperature conditions.

If you still have questions about the discussion of this topic, you are

welcome to email us on the official website of SES power.