What are the components and functions of the protection board in the

lithium battery combination? What is the difference between overcurrent

protection and short circuit protection?

The lithium battery protection board is an integrated circuit board

specially designed for lithium batteries. It is almost an inevitable partner

with lithium batteries. The reason is very simple. The chemical characteristics

of lithium batteries themselves determine the harsh conditions of use (of

course, this is relative to lead-acid batteries.) For batteries): cannot be

overcharged, overdischarged, overcurrent, short circuit and ultra-high

temperature.

SES Power's lithium battery products often use BMS or PCM with different

specifications and performance. Some BMSs have RS485, CANBus and other

communication protocols, which are more intelligent. For example, they use

square lithium iron phosphate cells, which can directly replace lead in the same

size. Acid battery 12V100Ah, 12V200Ah, 24V100AH, string energy storage system,

wall-mounted home energy storage system, etc. Below, our senior engineers

briefly explain the composition and basic principles of PCM for you.

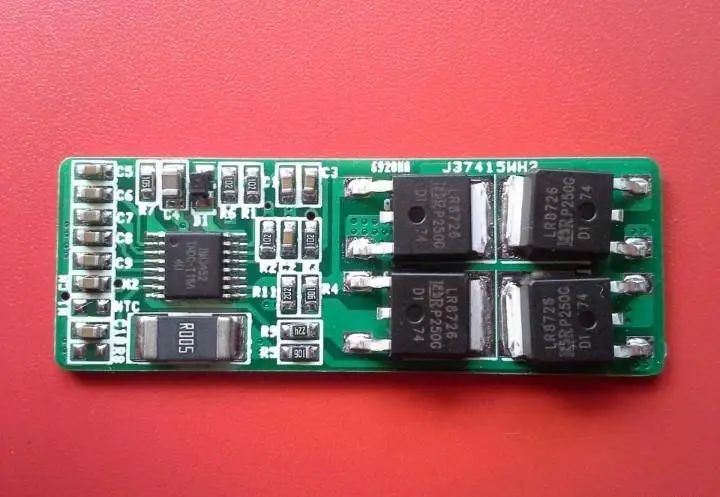

The lithium battery protection board is usually composed of a control IC, a

switch tube, precision resistors, NTC, PTC, ID memory, etc. The control IC

controls the switch tube to conduct when the lithium battery pack is normal, so

that the cell communicates with the external circuit. When the cell voltage or

loop current and temperature exceed the specified value, it immediately (tens of

milliseconds) controls the switch to turn off to protect the safety of the

cell.

NTC is the abbreviation of Negative temperature coefficient, that is, a

negative temperature coefficient resistor. When the ambient temperature

increases, its resistance value decreases. The ID memory is often a single-line

interface memory. The ID memory stores information such as the type of lithium

battery pack, production date, etc., which can be used for product traceability

and service life information.

PTC is the abbreviation of Positive Temperature Coefficient in English. It

is a positive temperature coefficient resistance. PTC in the lithium battery

pack can prevent the high temperature discharge of the lithium battery pack and

the occurrence of unsafe high current. According to the voltage, current density

characteristics and application environment of the lithium battery pack, there

are special requirements for PTC.

The functions of overcharge protection, overdischarge protection, and

temperature protection of PCM are relatively simple, and we will not explain

them in detail. However, many engineers do not have a very correct understanding

of over-current protection and short-circuit protection. We will focus on these

two points.

Overcurrent protection: Overcurrent protection of lithium battery pack

Definition: When the output current of the battery pack P+ and P- exceeds the

overcurrent/short circuit current value and reaches the overcurrent delay, the

control circuit controls the discharge switch to turn off the discharge circuit

and stop discharging. Excessive current requires a continuous process to

generate heat accumulation. Therefore, there are generally two protections for

overcurrent. The setting value of the first protection is relatively small, the

delay time is relatively long, and the setting value of the second protection is

relatively large, the delay time is very short. When the overcurrent protection

is activated, the loop current instantly becomes 0A. To restore the protection

state, there are generally two conditions:

1) No manual intervention is required. After a period of time, the circuit

is automatically opened. If it is still in the overcurrent state at this moment,

the lithium battery pack will enter the protection again. If the overcurrent is

removed, the lithium battery pack will enter the working state.

2) Manual intervention is required. After the load or charger is removed,

manually reset the overcurrent protection.

During the normal discharge process of the lithium battery pack to the

load, when the discharge current passes through the two switch tubes in series,

a voltage will be generated at both ends of the switch tube due to the

on-resistance of the switch tubes. The voltage value U=I×RDS×2 (RDS is the

on-resistance of a single switch tube), the control IC detects the voltage

value. If the load is abnormal for some reason, the loop current will increase.

When the loop current is large enough to make U > 0.1V (this value is

determined by When the control IC determines that different ICs have different

values), the control IC turns Q1 from on to off, thereby cutting off the

discharge loop, making the current in the loop zero, and playing an overcurrent

protection role.

There is a delay time between the control IC detects the occurrence of

overcurrent and sends the shutdown signal. The length of the delay time is

determined by C2, usually about 13 milliseconds, to avoid misjudgment caused by

interference. In the above control process, the overcurrent detection value

depends not only on the control value of the control IC, but also on the

on-resistance of the switch. the smaller the value.

Short-circuit protection: In fact, it is also a kind of over-current

protection, but when the system is short-circuited, the current will

theoretically become infinite, so the heat generated is infinite. If you want to

wait until the software responds to protect, the lithium battery pack may be

Therefore, the short-circuit protection is generally triggered automatically by

hardware, and a signal can be sent to the control IC after triggering.

When the output currents of the lithium battery packs P+ and P- exceed the

short-circuit current value and reach the short-circuit delay, the control

circuit controls the discharge switch to turn off the discharge circuit and stop

discharging. Short-circuit protection is a limit form of over-current

protection. Its control process and principle are the same as over-current

protection. Short-circuit protection is equivalent to adding a small resistance

(about 0Ω) between P+ and P- to make the protection board. The load current

reaches the set value instantaneously, and the protection board immediately

triggers short-circuit protection.