As secondary rechargeable batteries that have been widely used, lithium ion

batteries have penetrated into every aspect of our lives. For most users, the

value of lithium-ion batteries is reflected in the discharge phase, and the

charging phase is completely ineffective and forced to waste time. Because of

this, manufacturers continue to improve the charging technology of lithium-ion

batteries. SES Power remembers that it took at least 1-2 hours to fully charge a

mobile phone ten years ago, and now a mobile phone only needs more than 20

minutes to be fully charged. It can be almost fully charged. The charging time

of the first-generation Tesla electric vehicles often took more than an hour to

get close to a full charge, but now it only takes about 40 minutes.

Of course, not all applications of lithium-ion batteries require fast

charging. SES Power is good at lithium battery energy storage, UPS backup power,

microgrid, home energy storage, etc. In fact, there is no urgent need for

charging time. On the contrary, sometimes it is necessary to appropriately

reduce the charging current to achieve the purpose of extending the charging

time (because the cost of the charger is proportional to the output power). We

use 12V, 24V, 36V, 48V series that can perfectly replace lead-acid batteries,

3Kw~20Kw (you can choose different capacity lithium batteries to match) home

energy storage system, photovoltaic power generation energy storage system,

large inverter (UPS) For supporting products, etc., it is necessary to consider

the charging conditions in the design stage, and try to choose the most

cost-effective charging solution.

Below we will look at the proposition of fast charging from a purely

technical point of view for lithium-ion battery applications that require fast

charging.

A: How fast is the charge to be called "quick charge"?

The basic demands of ordinary consumers for lithium-ion battery charging

are:

1) Charge fast;

2) Do not affect the battery life;

3) To save money as much as possible, try to charge as much electricity as

possible into my battery.

So fast can be called fast charge? There is no standard literature that

gives specific values. Let’s refer to the standards of the electric vehicle

industry for the time being. The entry-level fast charge is 3C, which

theoretically takes 20 minutes to charge. Of course, this is unrealistic. We

generally think that 80% full in 30 minutes can be recognized as fast charging.

According to this idea, 80% of the lithium-ion battery is fully charged in 15

minutes, which is equivalent to working in a 3.2C state of charge.

B: What is the bottleneck of fast charging?

In the general proposition of fast charging, it is necessary to classify

the surrounding areas, such as batteries, chargers, and power distribution

facilities.

When we discuss the proposition of fast charging, the first thing that

comes to our mind is whether there will be a problem with the battery. In fact,

before there is a problem with the battery, the first problem is the charger and

the power distribution line.

Tesla's charging pile, known as a super charging pile, has a power of

120kW. According to the parameters of Tesla Model S85D, 96s75p, 232.5Ah, and the

highest 403V calculation, its 1.6C corresponds to the maximum demand power of

149.9kW. It can be seen from here that for long-range pure electric models, 1.6C

or 80% full charge in 30 minutes has already constituted a test for the charging

pile.

In the industry and national standards, it is not allowed to directly set

up charging stations in the original residential electricity network, because

the power consumption of one fast charging pile has already exceeded the

electricity consumption of dozens of households. Therefore, charging stations

all need to set up 10kV transformers separately, and not all distribution

networks in a region have the margin to add more 10kV substations.

As for whether the battery can carry 1.6C or 3.2C charging requirements, it

can be viewed from both macro and micro perspectives.

C: The macroscopic fast charging theory of lithium batteries

The reason why the title of this section is called "Macroscopic Fast

Charging Theory" is that what directly determines the battery's fast charging

capability is the properties of positive and negative materials, microstructure,

electrolyte composition, additives, diaphragm properties, etc. inside the

lithium battery. Content. Let's put aside for a moment what's almost entirely

lithium-ion battery expertise, and then we'll stand entirely outside the battery

and see how lithium-ion batteries can be fast-charged in third vision.

C1: There is an optimal charging current for the battery

In 1972, American scientist J.A. Mas proposed that the battery has an

optimal charging curve and Mas's third law during the charging process. It

should be noted that this theory is proposed for lead-acid batteries, and the

boundary condition that defines the maximum acceptable charging current is a

small amount. The production of side reaction gases is obviously related to the

specific reaction type.

But the idea that there is an optimal solution in the system is universal.

Specific to lithium batteries, the boundary conditions that define their maximum

acceptable current can be redefined. Based on the conclusions of some research

literature, its optimal value is still a curve trend similar to Maas' law.

It is worth noting that the boundary conditions of the maximum acceptable

charging current of lithium batteries need to consider not only the factors of

lithium battery cells, but also system-level factors, such as different heat

dissipation capabilities, the maximum acceptable charging current of the system

is different. .

Then we will continue the discussion on this basis for the time being.

The formula description of Maas' theorem:

I =I0*e^αt

In the formula; I0 is the initial charging current of the battery; α is the

charging acceptance rate; t is the charging time. The values of I0 and α are

related to battery type, structure and condition.

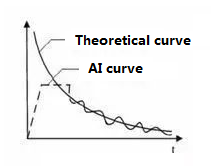

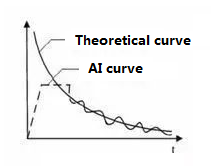

The current research on battery charging methods is mainly based on the

optimal charging curve. As shown in the figure below, if the charging current

exceeds this optimal charging curve, it will not only not improve the charging

rate, but also increase the gas evolution of the battery; if it is less than

this optimal charging curve, although it will not cause damage to the battery,

it will prolong the charging. time, reducing the charging efficiency.

The elaboration of this theory consists of three levels (Maas's third

law):

① For any given discharge current, the current acceptance ratio α when the

battery is charged is inversely proportional to the square root of the capacity

released by the battery;

② For any given discharge amount, α is proportional to the logarithm of the

discharge current Id;

③ After the battery is discharged at different discharge rates, its final

allowable charging current It (acceptance capacity) is the sum of the allowable

charging currents at each discharge rate.

The above theorem is the source of the concept of charge acceptance. The

charging acceptance capacity is the maximum capacity that can be used for a

rechargeable battery with a certain amount of charge under a specific

environment and condition without causing undue side reactions and adverse

effects on the life and performance of the battery cell. recharging current.

SES Power will further understand the three laws of mas for you:

The first law is that after the battery discharges a certain amount of

power, its charge acceptance capacity is related to the current charge capacity.

The lower the charge capacity, the higher the charge acceptance capacity.

The second law, during the charging process, pulse discharge occurs, which

helps to improve the real-time acceptable current value of the battery;

The third law, the charge acceptance capacity will be affected by the

superposition of the charge and discharge conditions before the charging

time.

If the Maas theory is also applicable to lithium batteries, the reverse

pulse charging (hereinafter referred to as the Reflex fast charging method) can

be explained by depolarization. Support for the pulse method.

Of course, the intelligent charging method that can really apply the Maas

theory is to track the battery parameters, so that the charging current value

always follows the Maas curve of the lithium battery, so that the charging

efficiency can be maximized within the safety boundary.

C2: Common fast charging methods

There are many charging methods for lithium batteries, and for the

requirements of fast charging, the main methods include pulse charging, Reflex

charging, and intelligent charging. Different battery types have different

charging methods.

C2.1 Pulse charging

The standard pulse charging method in the literature is that the pulse

phase is set after the charging reaches the upper limit voltage of 4.2V, and

continues above 4.2V (taking the ternary lithium battery as an example). Not to

mention the rationality of its specific parameter settings for the time being,

because there will be differences between different types of batteries.

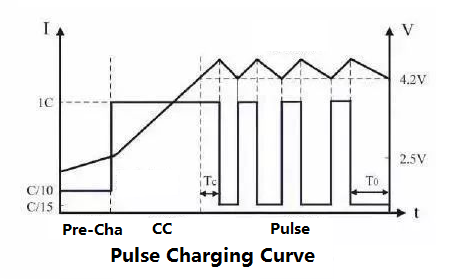

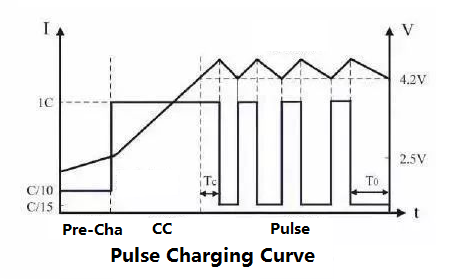

Let's focus on the pulse implementation process. The following is the pulse

charging curve, which mainly includes three stages: pre-charge, constant current

charging and pulse charging.

During constant current charging, the battery is charged with a constant

current, and part of the energy is transferred to the inside of the battery.

When the battery voltage rises to the upper limit voltage (4.2 V), the

pulse charging mode is entered: the battery is charged intermittently with a

pulse current of 1 C.

During the constant charging time Tc, the battery voltage will continue to

rise, and the voltage will slowly drop when charging stops.

When the battery voltage drops to the upper limit voltage (4.2 V), the

battery is charged with the same current value to start the next charging cycle,

and so on until the battery is fully charged.

During the pulse charging process, the battery voltage drop speed will

gradually slow down, and the charging stop time T0 will become longer. When the

constant current charging duty cycle is as low as 5% to 10%, the battery is

considered to be fully charged and the charging is terminated.

Compared with the conventional charging method, the pulse charging can be

charged with a larger current, and the concentration polarization and ohmic

polarization of the battery will be eliminated during the charging stop period,

so that the next round of charging can be carried out more smoothly, and the

charging speed is fast. The temperature change is small and the impact on

battery life is small, so it is widely used at present.

But the disadvantage is obvious: a power supply with limited current

capability is required, which increases the cost of the pulse charging

method.

C2.2 Intermittent charging method

The lithium battery intermittent charging method includes variable current

intermittent charging method and variable voltage intermittent charging

method.

C2.2.1 Variable current intermittent charging method

The characteristic of the variable current intermittent charging method is

to change the constant current charging to the voltage limiting variable current

intermittent charging.

In the first stage, the battery is charged with a larger current value, and

the charging is stopped when the battery voltage reaches the cut-off voltage V0,

and the battery voltage drops sharply at this time.

In the second stage, after a period of off-charging time, the charging is

continued with a reduced charging current.

In the third stage, when the battery voltage rises to the cut-off voltage

V0 again, stop charging, so the charging current for several times (generally

about 3 to 4 times) will reduce the set cut-off current value.

Finally, it enters the constant voltage charging stage, and charges the

battery with a constant voltage until the charging current decreases to the

lower limit value, and the charging ends.

In the main charging stage of the variable current intermittent charging

method, under the condition of limited charging voltage, the intermittent mode

of gradually decreasing current is adopted to increase the charging current,

that is, the charging process is accelerated and the charging time is shortened.

However, this charging mode circuit is relatively complex and expensive, and is

generally only considered for high-power fast charging.

C2.2.2 Variable voltage intermittent charging

On the basis of the variable current intermittent charging method, some

people have studied the variable voltage intermittent charging method. The

difference between the two lies in the charging process in the first stage,

which replaces the intermittent constant current with the intermittent constant

voltage.

In each constant voltage charging stage, due to the constant voltage, the

charging current naturally decreases according to an exponential law, which is

in line with the characteristic that the acceptable rate of battery current

gradually decreases with the progress of charging.

C2.2.3 Reflex fast charging method

The Reflex fast charging method, also known as the reflex charging method

or the "hiccup" charging method. Each working cycle of this method includes

three stages: forward charge, reverse instantaneous discharge and stop

charge.

It solves the phenomenon of battery polarization to a large extent and

speeds up the charging speed. But reverse discharge will shorten lithium battery

life. SES Power is here to remind you that lead-acid batteries are the biggest

beneficiaries of this approach.

C2.2.4 Intelligent charging method

Intelligent charging is a more advanced charging method at present. The

main principle is to apply du/dt and di/dt control technology: by checking the

increment of battery voltage and current to judge the battery charging state,

dynamically track the acceptable charging current of the battery, and make

charging the current is always around the maximum charging curve that the

battery can accept.

This kind of intelligent method generally combines advanced algorithm

technology such as neural network and fuzzy control to realize the automatic

optimization of the system.

At the end of the article, SES Power needs to remind you that many

customers often ask whether they can use the original lead-acid charger for

lithium-ion batteries after purchasing the 12V100Ah and 24V100Ah (lead-acid

replacement products) of our lithium iron phosphate batteries. The answer to the

question of charging is: the characteristics of lithium-ion batteries are

different from those of lead-acid batteries. Do not use lead-acid battery

chargers to charge lithium-ion batteries, even if the charging voltage

parameters are the same!