Knowledge and design focus of high-performance soft pack lithium battery

pack

The battery module can be understood as a product formed by the combination

of lithium-ion cells in series and parallel, and the addition of BMS. The

structure of the pack must support, fix and protect the cells. These functions

can be summarized into three major items: mechanical strength, electrical

performance, thermal performance and fault handling capability.

Mechanical strength: whether it can fix the position of the cell well and

protect it from deformation that damages performance;

Electrical performance: how to meet the current-carrying performance

requirements, how to meet the control of the temperature of the cell, and

whether it can be powered off in the event of a serious abnormality;

Thermal performance and fault handling capabilities: Avoiding the spread of

thermal runaway, being able to sense the SOH state of the battery in advance,

and being able to alarm or protect itself, etc., are one of the criteria for

judging the quality of battery modules. For high-performance battery modules,

their thermal management solutions have turned to liquid cooling or phase change

materials.

SES Power often uses CATL, EVE square aluminum shell lithium iron phosphate

for production, such as our 12V100Ah, 12V200Ah, 24V100Ah, 24V200Ah, 36V100Ah,

48V50Ah, 48V100Ah, 48V200Ah, 72V100Ah, 12V30Ah, 12V50Ah using high-performance

lithium batteries , 12V60Ah start-up battery (the maximum peak current can reach

1500A), etc., but we also use soft-pack lithium batteries in many products,

because the energy density of soft-pack batteries is in the three common lithium

battery packaging forms, energy The volume ratio is optimal. But at the level of

pack design, because the soft-packed cells do not have a steel shell for

protection, the pack must protect the soft-packed lithium battery cells.

The following is a detailed explanation of the knowledge and key points of

the pack design of the soft-pack power lithium battery pack by SES Power.

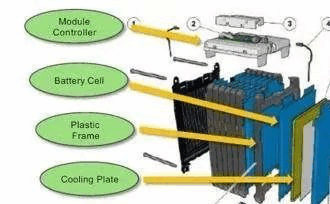

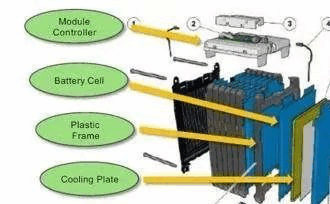

A: The main components of the module

The above picture is a typical form. Its basic components include: BMS,

battery cells, conductive connectors, plastic frames, cold plates, cooling

pipes, pressure plates at both ends, and a set of fasteners that combine these

components. The pressure plates at both ends not only gather the single cells,

but also provide a certain pressure.

B: Structural Design

Structural design requirements: anti-vibration and anti-fatigue; process

controllable: no over-welding, virtual welding, to ensure 100% no damage to the

cell; high automation cost; easy maintenance and repair; necessary heat transfer

isolation to avoid rapid spread of thermal runaway.

C: Thermal Design

The physical structure of the soft-packed cell determines that it is not

easy to explode. At the same time, soft-packed cells are also the best in heat

dissipation among several cell structures.

The well-known representative of the soft-pack power battery pack, Nissan's

Leaf, has a fully sealed structure and does not consider heat dissipation.

Leaf's frequent feedback in the market is too fast, which is obviously related

to thermal management. Obviously, pouch cells must have an active thermal

management structure.

The current mainstream cooling methods have been transformed into liquid

cooling and phase change material cooling. Phase change material cooling can be

used in conjunction with liquid cooling, or alone in less severe

environments.

There is also a process that is still widely used, which is glue (the

thermal conductivity of which is much larger than that of air). The thermal

energy of the cell will be transferred to the module housing by the thermally

conductive adhesive, and then further dissipated to the environment. In this

way, it is unlikely that the cells will be replaced individually again, but the

propagation of thermal runaway is also prevented to a certain extent.

D: Electrical Design

Electrical design, including low-voltage and high-voltage parts.

Low-voltage design generally needs to consider several functions:

collecting battery voltage and temperature information on the controller;

generally designing a balance function (active balance or passive balance or

both) on the controller; a small number of relays to control the switch

function; Transmit module information through CAN communication.

The high-voltage design mainly refers to the series and parallel connection

between the battery cells and the battery cells, as well as the connection

conduction mode between the modules and the modules outside the module. These

high-voltage connections need to meet two requirements: first, the distribution

of conductive parts and contact resistance between the cells should be uniform,

otherwise the single-cell voltage detection will be disturbed; second, the

resistance should be small enough to avoid the electric energy on the

transmission path. waste.

E: safety design

Safety design can be divided into three requirements: good design to ensure

that no accident occurs; early warning; accident or failure has occurred, it

needs to prevent the accident from spreading too fast.

To achieve the first requirement, a reasonable layout, a good cooling

system, and a reliable structural design are required; for the secondary

requirement, the sensors need to be more widely distributed to every possible

fault point, comprehensively detect voltage and temperature, and it is best to

monitor every possible fault point. The internal resistance of a cell; the final

requirement is to set a fuse through the cell and the module, set a firewall

between the modules, and design strength redundancy to deal with possible

structural collapse after a disaster.

F: Lightweight Design

The main purpose is to pursue the energy volume ratio. There are many ways

to reduce weight, such as increasing the energy density of the cell; in the

detailed design, pursue the thinness of the structure while ensuring the

strength (such as choosing a thinner material and digging a larger hole in the

plate); replacing it with aluminum Sheet metal parts; use new lower density

materials to build shells, etc.

G: Standardized Design

Standardization is the cornerstone of reducing costs and improving

interchangeability. Specific to the power battery module, there is an additional

purpose of cascade utilization.