Influence of lithium-ion batteries in series and parallel on the

performance of battery packs

Due to the limited voltage and capacity of the single battery, in order to

meet the high voltage and large capacity requirements of electrical equipment

and energy storage systems, lithium-ion batteries are usually used in series,

parallel or a combination of series and parallel.

However, inconsistencies will inevitably occur in the manufacturing process

of lithium-ion batteries, and the degree of inconsistency will be gradually

amplified with the prolongation of use time and the increase of cycle life.

Typical parameters of lithium-ion batteries, such as AC internal

resistance, DC internal resistance, voltage and other parameters will also be

different under different states of charge. Under the barrel effect, individual

bad cells will lead to the failure of the entire energy storage system.

Therefore, the series and parallel modes of lithium-ion batteries have a huge

impact on the performance of the battery system.

SES Power has rich experience in the R&D and production of customized

lithium battery packs. 48V200Ah, 72V100Ah, 120V80AH, 12V30Ah, 12V50Ah, 12V60Ah

starting batteries with high-performance rate lithium batteries (the maximum

peak current can reach 1500A), etc. In the process of making these products, we

always connect the cells in series and parallel. Let SES Power explain to you

the relevant knowledge of series and parallel connection of lithium

batteries.

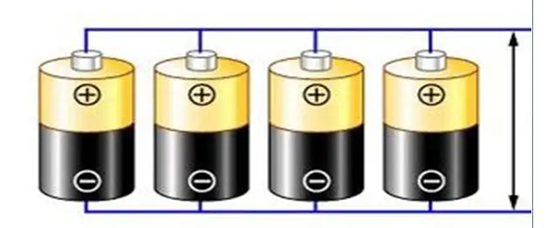

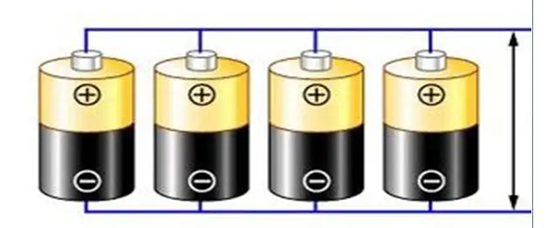

A: Parallel:

In the actual parallel application of lithium-ion batteries, the parallel

branch is affected by the consistency of the battery, and the current imbalance

will occur during operation. The current of the parallel branch is also affected

by the parameters of this branch and other branches. influences.

When lithium-ion batteries are grouped in parallel, the DC internal

resistance and line impedance of the battery (the farther from the output end,

the greater the impedance) will cause the actual current through each cell when

the capacity and initial state of the single battery are the same. Not the same,

especially in the state of high current. This will eventually cause individual

cells to be in a state of current that is much larger than that of other cells

(even if the terminal voltage is constant, the current fluctuation time is very

short), and eventually individual cells are more prone to decay than other

cells.

B: Concatenation:

The equipment or energy storage system needs a certain voltage to work, and

the voltage of a single battery cannot meet the requirements of the equipment

and system. At this time, multiple cells need to be connected in series to

achieve the rated working voltage.

The platform voltage of lithium-ion batteries varies according to the

positive and negative electrode materials. For example, for lithium-ion

batteries with graphite as the negative electrode material, when lithium iron

phosphate is used as the positive electrode material, the platform voltage is

3.2V; when the positive electrode material is selected from ternary materials,

The platform voltage is 3.7V; when the negative electrode material becomes

lithium titanate, the platform voltage will change with the change of the

positive electrode material.

Affected by the inconsistency in the production and manufacturing process

of single cells, the capacity and internal resistance of the single cells will

eventually affect the charge-discharge curve of the cells because the current

flowing through the cells is the same when the cells are used in series. When

each cell is in a different position in the battery pack, temperature will

become the biggest factor affecting the cells in series.

The cell in the middle of the battery pack needs to be dissipated to the

peripheral cells for heat dissipation, so its temperature is much higher than

that of the peripheral cells, so it is easier to polarize and attenuate.

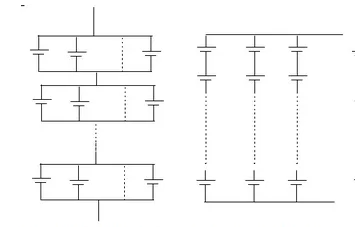

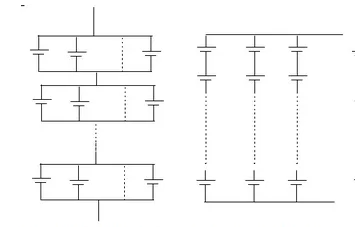

C: series-parallel hybrid:

Single cells can be connected in series to meet the voltage requirements,

and parallel to meet the capacity requirements. The series-parallel connection

often exists at the same time.

The typical series-parallel method of battery packs includes

parallel-connection first, series-connection first, and series-parallel

connection first. Of course, there are also more complex topologies of

series-parallel hybrid. The power usage usually adopts the method of first

parallel and then series, and the energy storage system generally adopts the

connection method of first series and then parallel.

The battery topology structure of series first and then parallel is

conducive to the detection and management of each single battery of the system.

In the series-before-parallel connection mode, the more the number of series

batteries in the parallel branch, the closer the battery parameters of the whole

branch, such as internal resistance and polarization, are. At this time, the

capacity difference of the parallel branch and the initial SOC difference become

the main factors that cause the parallel current unbalance.

However, referring to the information on the grouping method of the

relevant power battery packs, from the perspective of the reliability of the

battery pack connection, the trend of voltage inconsistency, and the impact of

the battery pack performance, the parallel connection method is better than the

series connection method.

In terms of system connection reliability, the first parallel and then the

series is higher than the single battery, while the reliability of the first

series and then the parallel is lower than that of the single battery; in terms

of battery voltage inconsistency, the voltage distribution of the group mode of

the first parallel and then the series is more concentrated. There is no battery

with too low voltage, and the battery pack using the series-first-parallel

grouping method is generally low in voltage and has a large voltage distribution

range.

It can be seen from the above that the series-first-parallel and the

first-parallel-to-series have their own advantages and disadvantages. Under

different application conditions, the appropriate grouping method should be

selected according to the usage, battery system capacity, charging and

discharging conditions, etc.