As the energy density requirements of the battery continue to increase, the

size space is getting smaller and smaller, so the slight gas expansion of the

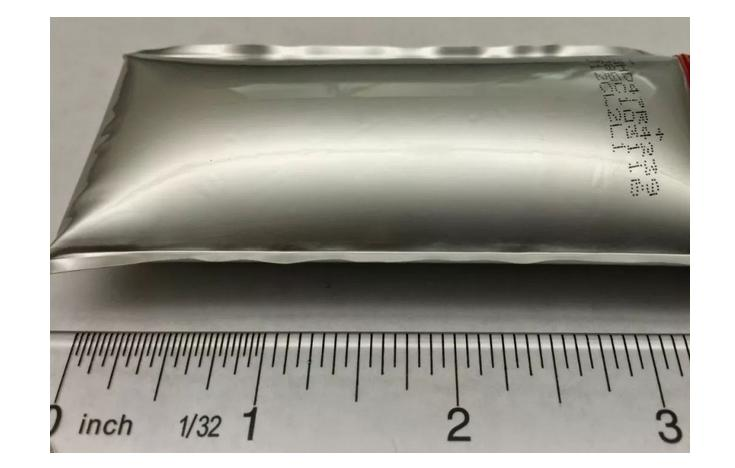

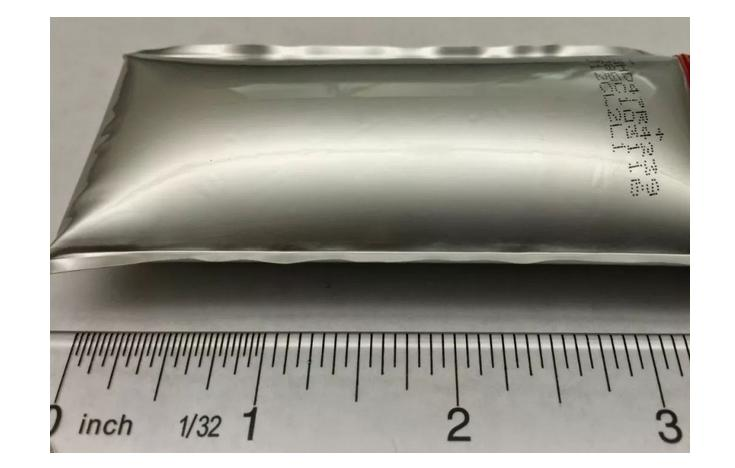

soft packaging lithium-ion battery will cause the battery to bulge, which will

affect the normal performance. In severe cases, it will break the packaging

aluminum foil and cause leakage. Liquid causes a risk of corrosion.

This article analyzes the types and possible causes of bloating, and

proposes solutions for your reference.

1. The type of gas produced

The gas production of soft-packaged lithium-ion batteries is divided into

two types: normal gas production and abnormal gas production. Normal gas

production refers to the formation process in the cell production process, often

referred to as formation gas production. This kind of gas can generally be

exhausted in the subsequent process without significant impact on the cells.

Abnormal gas production refers to the abnormality in the battery after the

packaging is completed, resulting in excessive gas volume. In this case, the gas

cannot be discharged, causing the battery cell to swell and causing performance

deterioration. When the internal pressure is too high, it is easy to open the

packaging aluminum foil, causing serious damage such as liquid leakage and

corrosion.

There are many factors that can cause abnormal gas production, which can be

divided into several categories: First, the SEI film on the negative electrode

surface may fall off or become loose during the subsequent cycle of the cell

itself, and the SEI film may be reconstructed, accompanied by gas generation;

The second is caused by the excessive water content inside the battery; the

third is the abnormal gas production caused by the internal short circuit of the

battery; the fourth is the gas production during high-temperature storage; the

fifth is the overcharging and over-discharging gas production.

Among them, the compactness and stability of the film formation are the

prerequisites for ensuring the performance of the battery cell. Excessive water

content and internal short circuit of the battery are frequent problems in the

production process.

2. Analysis of the causes of abnormal gas production

1) Abnormal flatulence with water content

Due to the sensitivity of the entire battery system to moisture, when

excessive moisture is present, not only the battery performance is reduced, but

also a large amount of gas is generated, which may cause more serious safety

problems. Therefore, moisture control is a prerequisite for the production of

lithium-ion batteries, and it is also a process parameter that needs to be

strictly controlled during the production process of flexible packaging

batteries.

The performance of cells with excessive moisture content is concentrated on

two points: one is that the hydrogen content in the gas composition is

significantly increased, and the other is that the capacity of the flatulence

cell is smaller than that of the normal cell from the perspective of the

formation capacity. This is due to a series of side reactions that occur inside

the battery cell.

There are many reasons for the excessive water content inside the cell, but

they can be roughly divided into two categories: one is due to poor packaging,

and subsequent moisture in the air enters the cell; the other is moisture

control during the production process Caused by bad.

2) Internal short-circuit flatulence

During the battery production process, when an internal short-circuit point

occurs, the local temperature rises sharply, causing the electrolyte to

decompose. Analysis of the gas composition of this type of flatulence battery

reveals that the CO2 content greatly increases and swelling occurs.

3) High temperature storage and overcharge and over discharge

In the process of high temperature storage and overcharge and

overdischarge, the positive electrode material is in a metastable state,

extremely unstable, and a series of decomposition reactions will occur. This

process will also produce gas and the battery cell will swell.

3. Measures to restrain abnormal gas production

Suppressing abnormal gas production needs to start from two aspects:

material design and manufacturing process.

First of all, the material and electrolyte system must be optimized on the

design side. For the treatment of the electrolyte, the method of adding a small

amount of film-forming additives is often used.

In addition, the surface coating of the positive electrode material can not

only increase the structural stability of the material, but also reduce the

contact between the positive electrode and the electrolyte, and reduce the gas

generated by the catalytic decomposition of the active positive electrode.

Secondly, it is necessary to strictly control the manufacturing process

parameters to ensure the reliability of the packaging and prevent the flatulence

caused by excessive moisture inside the battery. The control method is as

follows:

(1) After the winding of the battery core is completed, dry it sufficiently

to prevent the moisture content in the diaphragm from exceeding the

standard;

(2) Strictly control the time from the battery cell to the liquid injection

after the vacuum baking and the humidity of the drying room;

(3) Ensure the tightness of the liquid injection glove box;

(4) Control the moisture and free acid content in the electrolyte;

(5) Standardize the storage environment and sealing conditions of the

electrolyte to prevent excessive moisture from entering the electrolyte during

use and storage;

(6) Adopt closed-mouth pressurization formation or external airbag

formation after vacuum sealing and exhaust;

(7) Adopt multi-step formation and high-temperature shelving process to

ensure complete gas production;

(8) Improve package reliability.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate battery is a perfect

replacement for lead-acid batteries, and it is the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.