We know that lithium-ion and lithium-polymer batteries and battery packs have the advantages of high energy density, light weight, long battery life, and no memory effect, but they also have disadvantages such as poor safety and the need for circuitry to protect.

These characteristics make lithium-ion batteries ideal for portable electronic systems, energy storage systems, and power systems, but lithium-ion batteries need to operate within rated limits or their performance and safety cannot be guaranteed.

Therefore, in the actual application process, lithium batteries have different fault conditions, such as overvoltage OV, undervoltage, discharge overcurrent OCD and overheating OT, etc., so PCM and BMS containing professional protection ICs are very important for lithium batteries. Accessories.

As SES Power with 20 years of rich experience in the customized lithium battery industry, our products are mainly focused on energy storage system integration and lithium batteries in special scenarios, so we have a deep understanding of BMS and PCM. Our products, such as fully intelligent lead-acid replacement products with Bluetooth or RS485 communication (lithium iron phosphate 12V100Ah, 12V200Ah), CCA2000A lithium iron phosphate high-current start-up lithium battery (direct replacement for automotive lead-acid start-up batteries), UPS high-voltage lithium Battery system (up to 860V), 3Kw~20Kw off-grid, grid-connected, island-type lithium battery energy storage system, base station communication backup battery system (standard 19 inches), full set of photovoltaic energy storage components, normal charge and discharge in -40 degrees Celsius environment Lithium batteries, etc., almost all use professional-grade ICs and BMSs.

We are very familiar with the application scenarios of lithium iron phosphate batteries and ternary lithium batteries. Let our senior engineers analyze the knowledge of lithium battery protection IC for you.

A: As long as lithium batteries use the same protection IC?

Different manufacturers and different types of protection ICs and monitoring ICs actually have some similarities in application, because their protection objects are all lithium batteries.

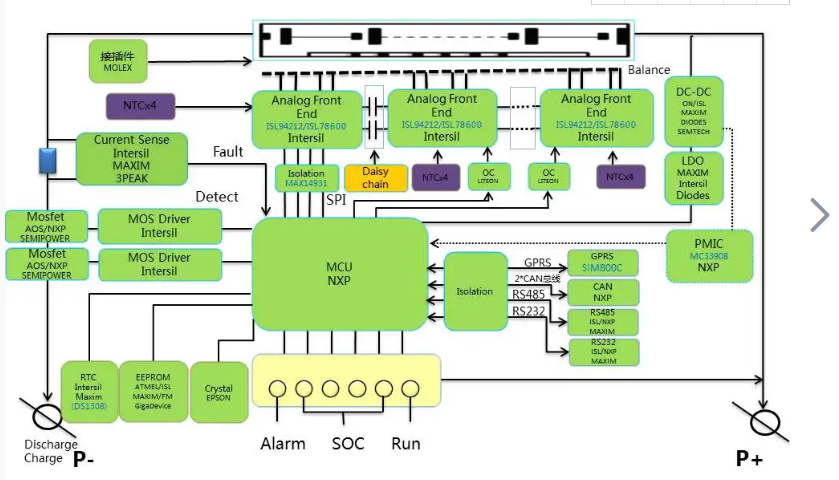

These battery management ICs signal or respond directly to the system when one or several monitored values (voltage, current, temperature) exceed limits. Such responses may be to signal the system, communicate with the system, or directly protect against charging or discharging. In some special cases, the response may even be to open the fuse directly.

So how to choose the most suitable one? This needs to be determined according to the type of battery pack.

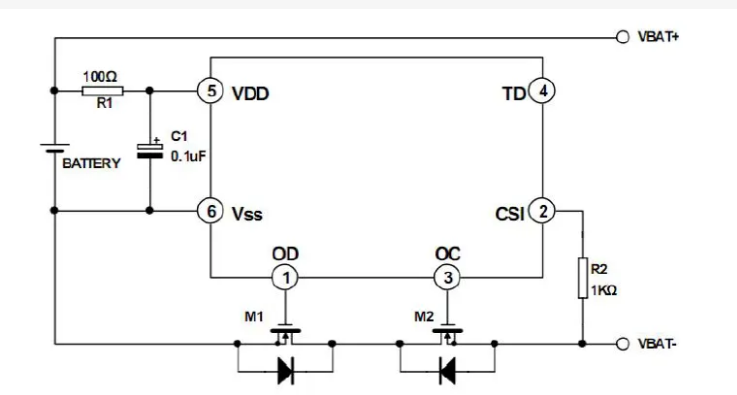

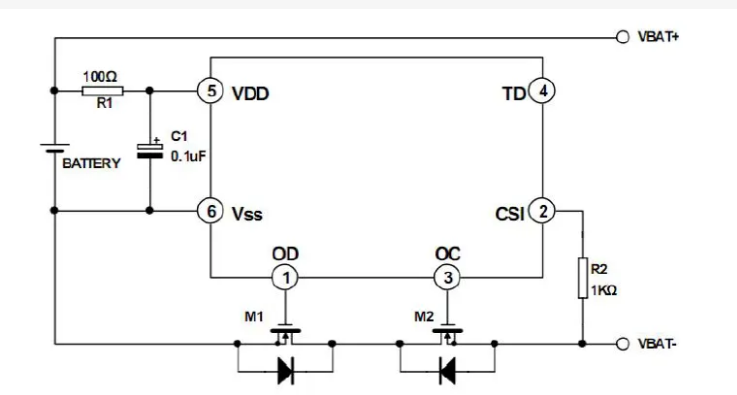

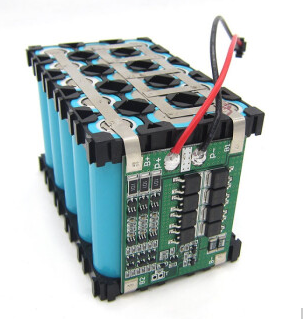

For a simple battery pack, a simple protection IC and circuit can meet all protection needs. At the integration level, this category is the simplest hardware-based protection: protection against overvoltage, undervoltage, temperature faults, or current faults for Li-ion batteries.

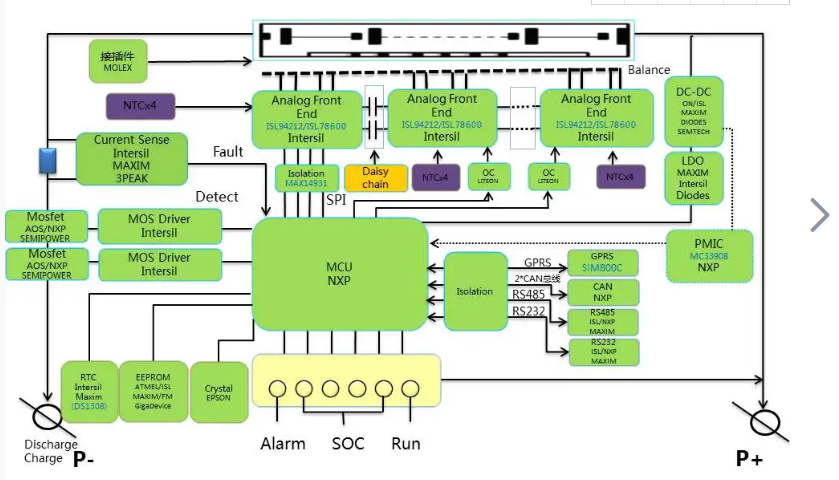

In environments used in higher cell count batteries, the IC needs to measure the voltage, battery current, and temperature of a single cell and collect these values. There also seems to be a need to provide a cell balancing function with the aim of extending battery runtime and extending battery life.

For more advanced battery packs, more intelligent ICs must be used, which are the most integrated ICs from an integration perspective. It includes the functions of a battery monitor and integrates advanced monitoring algorithms on top of it.

These ICs can report the battery's remaining capacity, runtime, and state-of-charge, and software-based protection further enhances battery protection. It enables the highest level of integration in the battery pack design.

B: What kind of function does the lithium battery protection IC generally have?

According to the needs of different protection types and protection levels, the protection functions now include discharge overvoltage protection, discharge overcurrent protection, charging overvoltage protection, charging overcurrent protection, temperature protection, etc.

In general, however, battery packs either require protection ICs that provide only the most basic overvoltage protection, or provide fully integrated various protection functions.

Some simple battery packs may only require basic overvoltage protection (OVP), a battery protection device that provides an accurate monitoring and trigger threshold for voltage in overcharge and overdischarge conditions. This type of IC with only overvoltage protection will monitor the external power FET. Once the monitored value exceeds the set value of the IC, the FET will be turned off.

The industry-leading accuracy of these most basic battery protection ICs is around ±10mV, and the undervoltage protection accuracy is around ±20mV.

Battery protection ICs that implement a complete set of voltage, current and temperature protection functions are now more available, and each cell can be independently monitored for overvoltage, undervoltage and open circuit conditions. Overheating detection is mostly done by adding an external NTC or PTC thermistor.

The lithium battery protection chip is the key to protect the safety of the battery pack. It can prevent the battery from overcharging, over-discharging and over-current. With the increasing application of high-voltage, high-capacity lithium battery packs, our requirements for ICs are also getting higher and higher. Of course, under the premise of ensuring the safety of the battery pack, it is the best thing that the battery protection IC can balance the battery and eliminate the individual voltage difference of the battery, because this can improve the performance of the battery pack.