Lithium element is very magical, SES Power analyzes the charging circuit

and the principle of protection circuit of lithium battery in depth for you

Secondary rechargeable batteries have penetrated into all aspects of

people's lives, but why choose lithium as the main force of secondary

rechargeable batteries? Why do lithium batteries need special charging and

protection circuits? How do these circuits work?

As SES Power with 20 years of rich experience in the customized lithium

battery industry, our products are mainly focused on energy storage system

integration and lithium batteries in special scenarios, such as fully

intelligent lead-acid replacement with Bluetooth or RS485 communication.

Products (lithium iron phosphate 12V100Ah, 12V200Ah), CCA2000A lithium iron

phosphate high-current starting lithium battery (direct replacement for

automotive lead-acid starting batteries), UPS high-voltage lithium battery

system (up to 860V), 3Kw~20Kw off-grid, grid-connected, island type Lithium

battery energy storage system, base station communication backup battery system

(standard 19 inches), full set of photovoltaic energy storage components, normal

charging and discharging lithium batteries under -40 degrees Celsius

environment, etc. Of course, we have very clear answers to the above questions.

Let our senior engineers answer them for you.

A: Why choose lithium for battery manufacturing?

Engineers are no stranger to lithium batteries. In the process of

developing electronic product projects, especially in projects that require

batteries for power supply, engineers will deal with lithium batteries.

This is because of the circuit characteristics of lithium batteries. As we

all know, the lithium atom ranks third in the periodic table of chemical

elements, containing 3 protons and 3 electrons, of which the distribution of the

3 electrons inside the lithium nucleus plays a decisive role in its chemical and

physical properties.

(Periodic Table of Elements)

Why choose lithium as the material of the battery? This is because,

although the outermost layer of a lithium atom has only one electron, its

relative atomic mass is only 7. In other words, under the condition of the same

mass density, lithium atoms carry the most electric energy. Taking aluminum as

an example for comparison, we can draw conclusions intuitively. Aluminum, which

ranks 13th in the periodic table, has 3 free-moving electrons in the outermost

shell, and has a relative atomic mass of 27. That is, if a battery is made of

aluminum with a mass of 27, its electric energy is 3; if a battery of the same

mass of 27 is used to make a battery, its electric energy is 27*(1/7), which is

about 3.86. Obviously, in terms of electrical energy, 3.86 of lithium is more

than 3 of aluminum.

This is the simplest theoretical explanation for why scientists choose

lithium for the development of secondary rechargeable batteries.

B: The charging circuit of lithium battery is very simple?

When engineers develop projects powered by lithium batteries, they face the

problem of charging lithium batteries. Taking the 18650 ternary lithium-ion

battery as an example, the maximum voltage of a single-cell lithium battery is

4.2V, that is, the limit voltage that the lithium battery can withstand does not

exceed 4.2V; the minimum voltage is 3.0V, which is the limit of the lithium

battery. The discharge voltage is not less than 3.0V.

In other words, its other layer of circuit significance is that the lithium

battery is being charged by the external charging circuit, and its final

charging voltage cannot be higher than 4.2V; when the lithium battery provides

working power to the external load, its safe voltage will stay at 3.0V;

Then the engineer directly charges the lithium battery with the commonly

used 5V/1A or 5V/2A charging circuit or charger. Is this possible?

The answer is obvious, no!

why? Because the charging voltage output by the 5V/1A or 5V/2A charger is

5V, which has exceeded the maximum withstand voltage of the lithium battery of

4.2V.

How to solve the problem of incompatibility between these two voltages?

Without changing the 5V/1A and 5V/2A specifications of the charger, how should

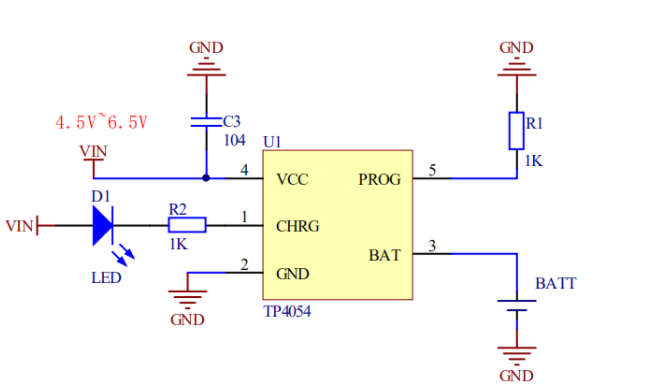

engineers implement it? A common circuit solution is to use a dedicated charge

management chip. These chips generally belong to the linear charging type of

constant voltage and constant current. The charging voltage is fixed at 4.2V,

the charging current supports a maximum of 800mA, and its own standby current

consumption is only 2uA.

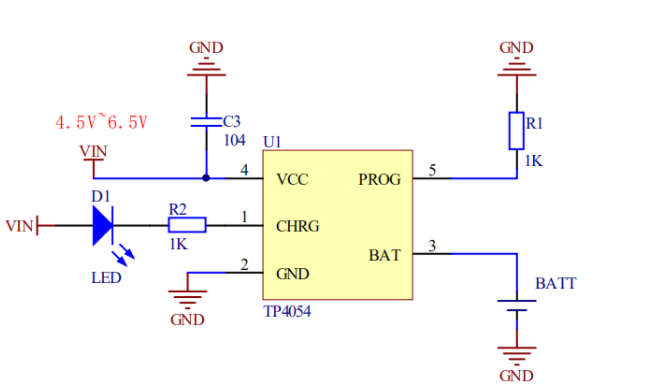

(Application circuit diagram of charging chip)

We can clearly observe that the scheme of the entire circuit design is very

simple, with only a few resistors, capacitors and LED lights in the peripheral

circuit. It perfectly solves the problem of single-cell lithium battery

charging.

C: The protection circuit of lithium battery is actually very easy to

understand

After explaining the charging circuit of a single-cell lithium battery,

let's talk about its discharging circuit.

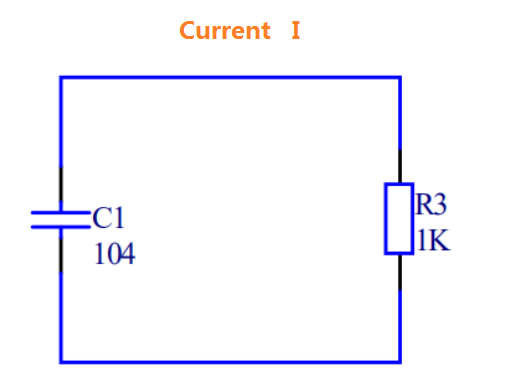

Charging is to absorb electrical energy from the outside world, and

discharge is to provide electrical energy to the outside world (load), which is

the mission of the battery. The discharge process of lithium batteries is

actually equivalent to the discharge process of capacitors. Both ends of the

capacitor are connected with a resistive load to form a simple working loop. If

the outside world does not interfere, the power stored in the capacitor will be

consumed until the power is zero.

Obviously, such a discharge process is completely unacceptable for lithium

batteries. The discharge of the lithium battery is zero, which is equivalent to

the voltage across the lithium battery is zero. If the lithium battery voltage

becomes zero due to the consumption of the load, the life of the lithium battery

will decrease exponentially.

This is why the lithium battery protection circuit is introduced.

Although the theory is so, how should it be operated in actual project

development? What solution can be solved? The following SES Power uses the most

common single-cell lithium battery protection IC-DW01 and 8205 MOS tube circuit

design schemes to explain the principle of the lithium-ion battery protection

circuit for you.

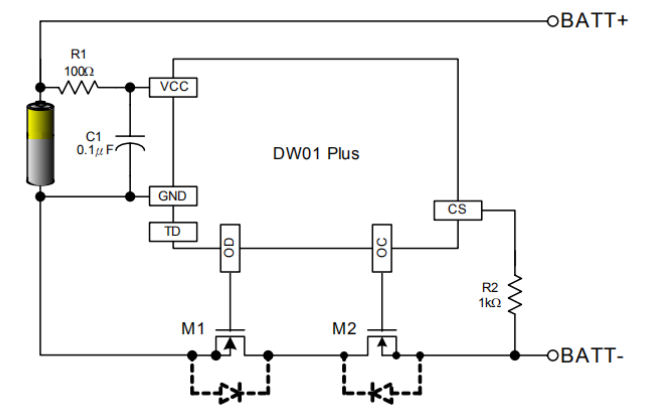

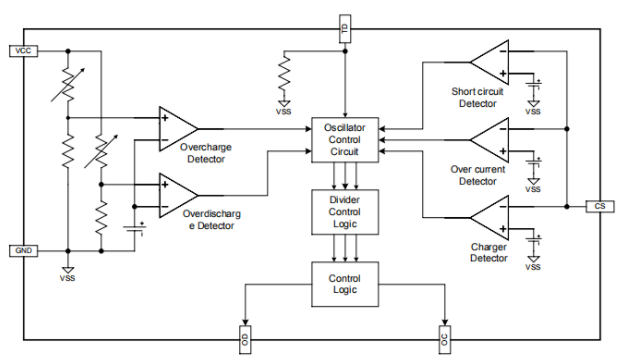

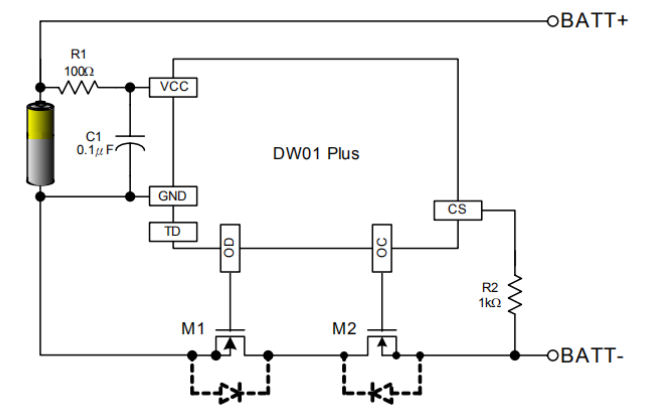

(DW01 chip and 8205 MOS tube application circuit)

In the application circuit diagram of DW01 chip and 8205 MOS tube, BATT+

belongs to the positive electrode of lithium battery discharge, and BATT-

belongs to the negative electrode of lithium battery discharge.

In the process of discharging the lithium battery to the outside world, the

OD pin of the DW01 chip controls the M1 MOS tube to turn on, and the OC pin

controls the M2 MOS tube to turn off. At this time, the lithium battery, the M1

MOS tube and the diode below the M2 MOS tube form a discharge loop.

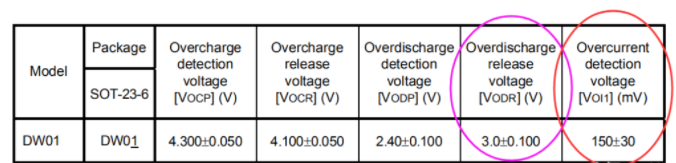

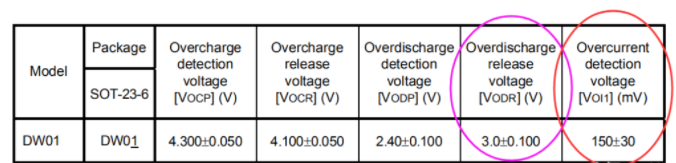

Two important parameters have to be mentioned, one is the discharge voltage

of the lithium battery, and the other is the discharge current of the lithium

battery, which are the core of the lithium battery protection circuit. Browse

the data sheet of the DW01 chip and learn

(DW01 chip parameters)

Another protection parameter is overcurrent protection. How do engineers

set this parameter? In order to set the discharge current protection value of

the lithium battery according to the actual project requirements, the key is to

understand the essence of the application circuit of the DW01 chip.

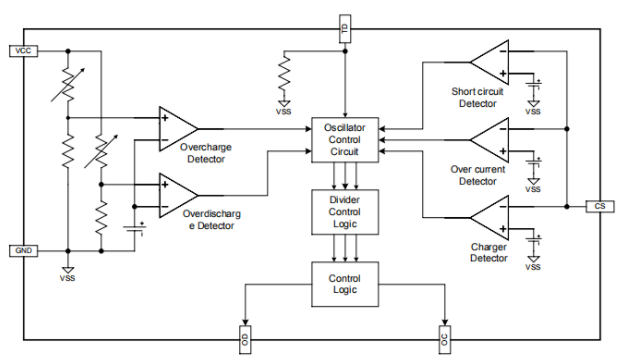

(DW01 chip internal circuit diagram)

DW01 chip Pin 2 pin CS, the internal circuit is connected to a comparator,

so when the lithium battery is discharged to the outside, if the voltage across

the pin CS is detected to exceed 150mV, then the lithium battery will be turned

off by turning off the MOS tube. The external discharge circuit of the battery

finally plays an overcurrent protection function.

The remaining question is the relationship between the voltage 150mV across

the pin CS and the quantification of the lithium battery discharge current?

Going back to the DW01 chip and the MOS tube application circuit diagram, the

lithium battery, the M1 MOS tube and the diode below the M2 MOS tube form a

complete discharge circuit. Because one end of the M1 MOS tube is connected to

the negative GND of the lithium battery, and the other end is connected to the

pin CS of the DW01 chip, and the pin CS detection protection voltage of the DW01

chip is 150mV, which is equivalent to the protection voltage of the two ends of

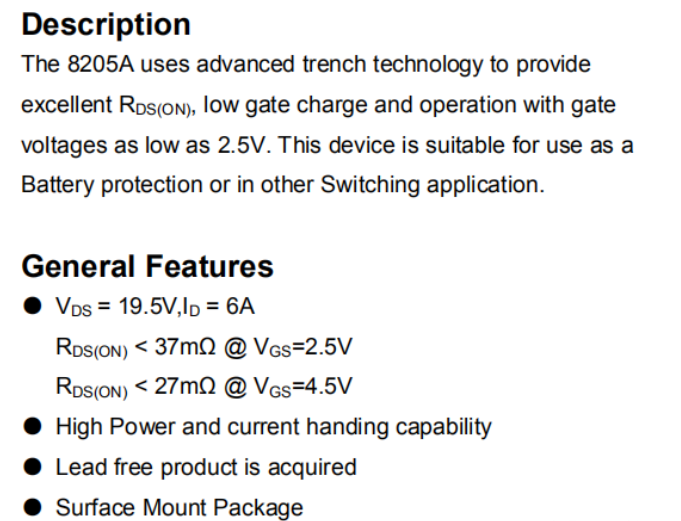

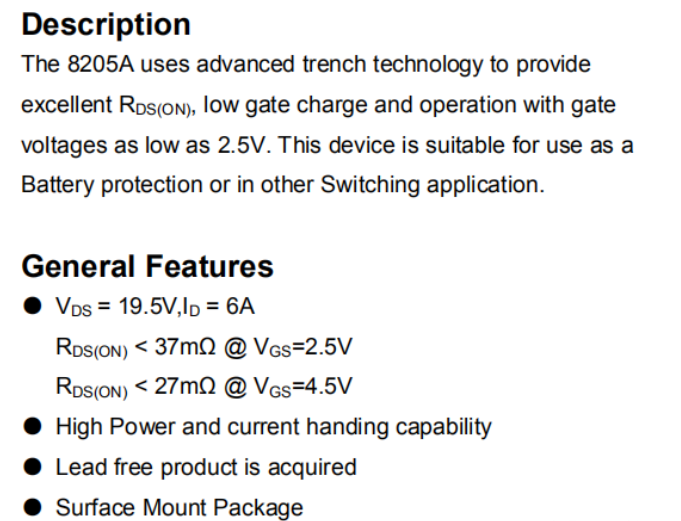

the M1 MOS tube is 150mV; Then browse the data sheet of the MOS tube and check

that its internal on-resistance is less than 37mΩ

(MOS tube parameters)

What is the discharge protection current of DW01 chip equal to? It is equal

to the pin CS detection protection voltage of 150mV divided by the on-resistance

of the 8205 MOS transistor (less than 37mΩ), which is about 5A.

So far, the discharge voltage protection and current protection principles

of the simplest lithium-ion battery have been fully explained for you. Although

some large lithium battery energy storage systems, such as SES Power's 48V200Ah

home wall-mounted energy storage system, 380V50Ah high-voltage UPS backup

lithium battery and other products, use a large number of cells in them, and the

situation of series and parallel connection is also very common. But the basic

principle is the same, you can deduce according to the above principle.

The follow-up SES Power will also explain the control principle and circuit

principle of the huge lithium-ion energy storage system in detail for you, so

stay tuned.