Recently, high temperature weather around the world has occurred frequently

due to the greenhouse effect and the El Reno phenomenon. Excessive temperature

not only leads to a decrease in power generation, but also seriously affects the

operating state and service life of photovoltaic modules, causing the insulation

performance of photovoltaic modules, cables, inverters and other electrical

equipment to decline, which may lead to short circuits, fires, and fires.

Endanger personal safety and property safety.

SES Power has many products that are matched with photovoltaic modules,

inverters and other clean energy components to form a complete and independent

lithium-ion battery energy storage system, such as the use of high-quality

square aluminum shell lithium iron phosphate battery lead-acid replacement

Products (12V100Ah, 12V200Ah), UPS, high-voltage lithium battery system for

high-power inverter (up to 860V), 3Kw~20Kw off-grid, grid-connected lithium

battery energy storage system, cabinet battery system (standard 19 inches),

smart wall mount Lithium-ion energy storage system, stacked lithium-ion energy

storage system, etc. Therefore, we have rich resources and experience in

photovoltaic modules, inverters and other ancillary products. Let our senior

engineers answer your questions about the impact and potential dangers of high

temperature climate on PV modules and inverters.

A: The impact of high temperature on various equipment of photovoltaic

power plants

a1: The effect of high temperature on the performance and power generation

of photovoltaic modules

Many users have a misunderstanding: when there is plenty of sunshine in

summer, is the power generation of photovoltaic power plants higher?

The answer is no, because the amount of power generation of photovoltaic

power plants is not determined by the single factor of sunlight, but by many

factors, among which the more critical factors are irradiance and ambient

temperature. The first characteristic of hot summer is high temperature, but

high temperature does not mean high irradiance and high performance of solar

modules.

Photovoltaic cell is a semiconductor device with negative temperature

characteristics, the higher the temperature, the worse the power generation

performance. The power is measured under standard conditions of 25°C. When the

panel temperature of the photovoltaic module is as high as 75°C, the loss of

power generation due to high temperature will reach 10% to 20%.

Therefore, the peak power generation of photovoltaic power plants often

occurs in late spring and early summer or late summer and early autumn. At this

time, the ambient temperature is suitable and the irradiance is high, which can

achieve the best conditions for photovoltaic power generation.

a2: Excessive temperature will lead to failure of photovoltaic modules

The main packaging material for photovoltaic modules is EVA, a plastic that

melts at temperatures above 80°C. Since photovoltaic modules usually have a

certain inclination angle during installation, when the temperature of the

photovoltaic module panel is too high, the internal EVA melts, and the

photovoltaic cells will sag due to gravity.

If the module is not fixed properly during the packaging process or the

internal fixation fails due to high temperature, internal short circuit, open

circuit and other faults will occur due to cell displacement and other reasons,

resulting in the module not working properly or damaged.

a3: Long-term high temperature accelerates the attenuation of photovoltaic

cells

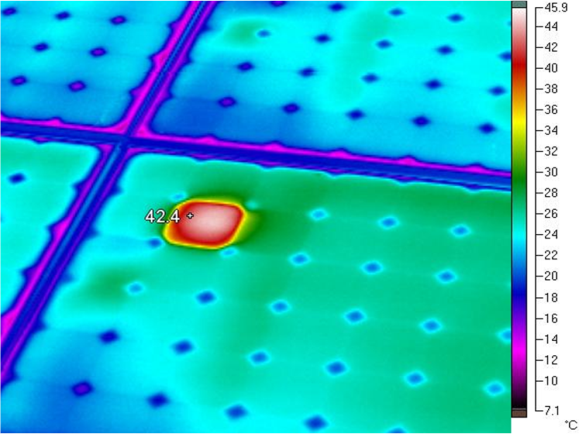

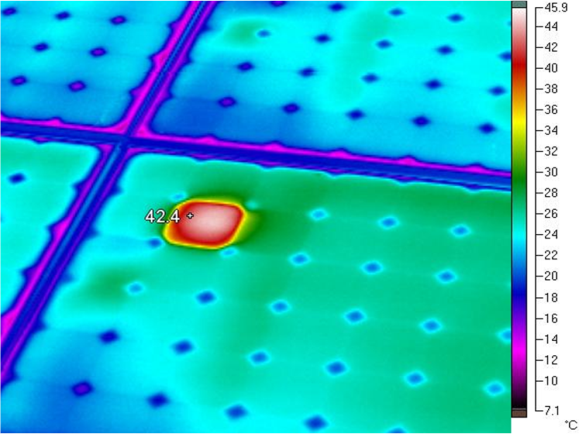

The high operating temperature of the cells will also aggravate various hot

spots, resulting in permanent deterioration or damage to the power generation

performance of the cells.

B: Influence of high temperature on cable and electrical insulation

High temperature has a direct negative impact on the performance and life

of insulating materials. Whether it is enameled wire of coils such as motors,

transformers, and inductors, or wires and cables such as various plastic wires,

they have limited resistance to high temperature. Excessive working temperature

will lead to problems such as the decline of insulation performance, and in

serious cases, it will lead to insulation collapse, causing short-circuit

explosion or fire.

C: Influence of high temperature on electronic equipment such as

inverters

c1: The photovoltaic power station has electronic equipment such as

inverters, which contain a large number of ordinary electronic components,

integrated circuits and high-power switching transistors. Usually, the working

temperature range of civil-grade electronic components is -35℃~70℃, and the

working temperature of most photovoltaic inverters is -30~60℃. Beyond this

operating temperature range, both ordinary electronic circuits and integrated

circuits will enter an unstable state. This state will lead to circuit equipment

shutdown in light, and serious circuit logic confusion and equipment damage.

c2: There will be a large number of electrolytic capacitors in the

photovoltaic inverter. At the same time, in order to stabilize the voltage of

the photovoltaic input terminal and prevent interference, there are usually

large-capacity electrolytic capacitors in varying numbers. These capacitors are

very afraid of high temperature, and high temperature will make the capacitors.

The internal electrolyte gradually volatilizes, resulting in a decrease in the

capacitance of the capacitor or even scrapping.

c3: The high-power thyristor in the photovoltaic inverter is also a device

that is sensitive to high temperature. Excessive temperature will affect the

correct operation and service life of the high-power thyristor. Excessive

temperature will cause the high-power thyristor to burn out.

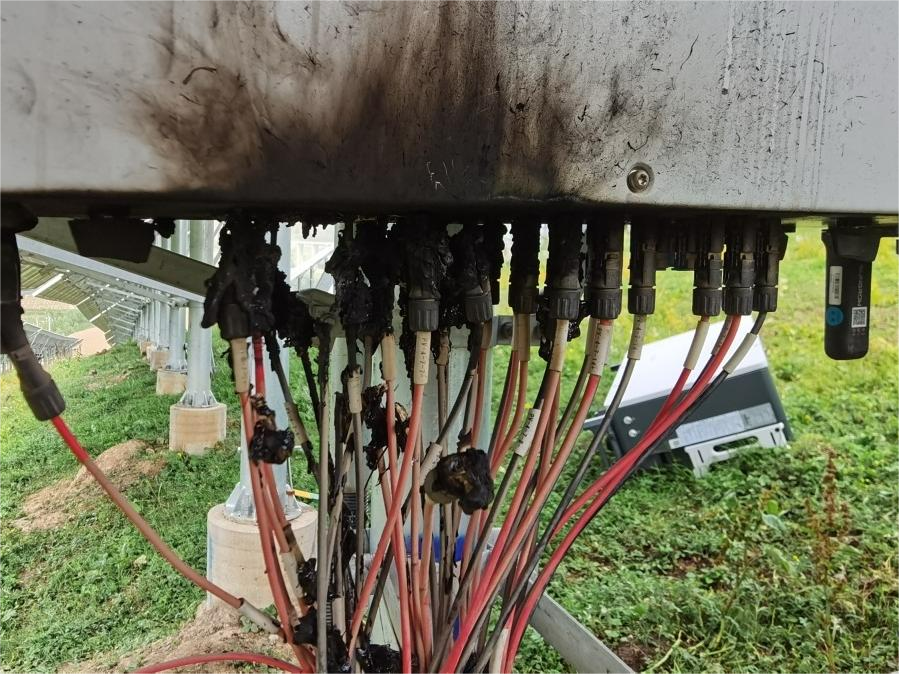

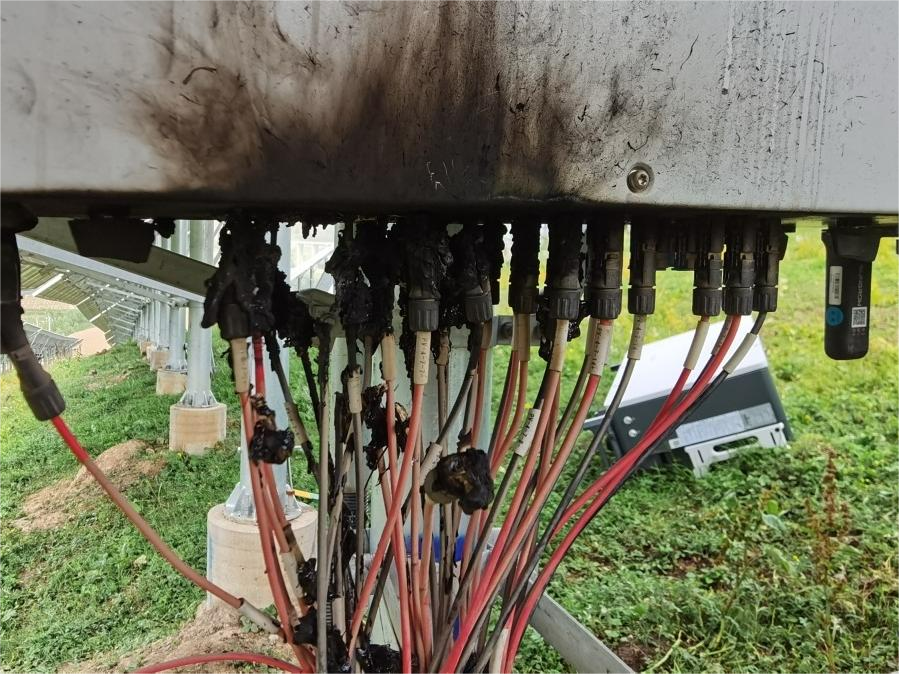

D: The effect of high temperature on photovoltaic connectors

International standard MC4 connectors are widely used for the connection

between photovoltaic power generation components and component strings, as well

as the DC terminal connection of combiner boxes, inverters and other

components.

The MC4 connector is a single-core connector, which has many advantages

such as good sealing, convenient connection, convenient maintenance and

maintenance. But it also has defects such as being afraid of high temperature,

easy to age, and afraid of rain. During the installation and use of component

connectors, avoid exposure to sunlight, high temperature, rain, etc., so as to

avoid aging of the connectors, corrosion of internal connectors, and cables,

resulting in increased contact resistance, or even ignition, resulting in a drop

in system efficiency or a fire accident.

In a small-scale photovoltaic power station, there are usually hundreds of

such connectors. The poor working condition of any one of them will affect the

increase of the internal resistance of the DC side, resulting in a decrease in

the power generation efficiency of the power station. The poor contact will

cause the connector to heat up or even burn the connector, which will lead to

the burning of the combiner box and the inverter, and even lead to a large-scale

fire.

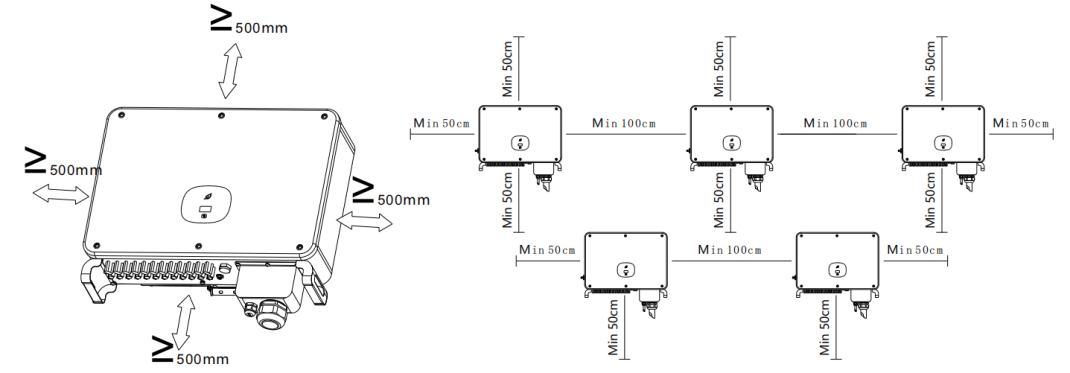

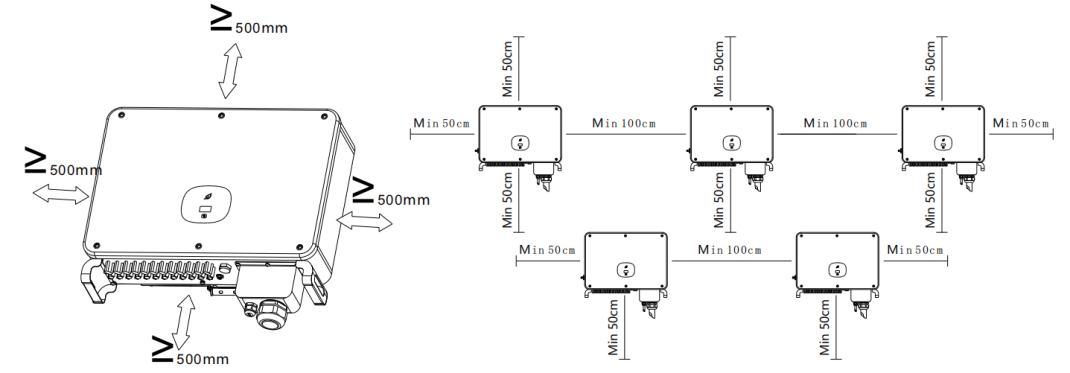

E: How to ensure the efficient work of the inverter?

e1: Ensure air circulation

Ensure smooth air circulation around the inverter. Do not install the

inverter in a small and closed environment. If multiple inverters are installed

on the same plane, it is necessary to ensure that there is enough distance

between each inverter. This not only It can ensure the ventilation and heat

dissipation of the inverter, and there is enough operating space for later

maintenance.

(Diagram of the distance between multiple inverters)

e2: Avoid the wind and the sun

Secondly, although many brands of inverters choose the protection level of

IP66 or IP65, it can reduce the chance of the inverter being exposed to wind,

sun and rain, which can prolong the service life of the inverter.

When installing the inverter, you can choose to install it at the bottom of

the module or under the eaves. If the inverter is installed on the roof of the

color steel tile, it is recommended to install the awning synchronously, which

can not only shelter from the wind and rain, but also reduce the direct

sunlight, reduce the temperature of the inverter, and ensure the power

generation efficiency.

e3: Pay attention to post-maintenance

After the inverter is installed, it is necessary to pay attention to the

later maintenance: regularly clean the fan, fan cover or heat sink to ensure the

heat dissipation and cooling of the inverter.

Usually, the inverter cooling technology adopts intelligent air cooling

technology, and the fan will intelligently adjust the speed according to the

internal temperature of the inverter. When the inverter works in a high

temperature environment, the intelligent air cooling technology can effectively

reduce the probability of load reduction and ensure that the The inverter can

run stably while extending the service life of the fan.

In addition, the inverter has a fan fault alarm function. The operation and

maintenance personnel can receive the alarm information in the monitoring

background, quickly and accurately locate the fault, which is convenient for the

operation and maintenance personnel to eliminate the fan fault in time, reduce

the power generation loss, and ensure the power generation income.

F: What should I do if photovoltaic modules, inverters, and lithium-ion

energy storage systems catch fire?

In the event of a fire accident in these devices, the energy inlet should

be closed first, the AC power supply should be cut off, and the various

connection circuits of the components should be disconnected as soon as possible

to ensure the safety of firefighting personnel and control the fire in the later

stage.

Firefighters must wear insulating shoes when entering the scene of an

accident, and insulating gloves when touching the equipment shell and frame. For

10-35kV high-voltage electrical fires, keep the minimum distance between the

fire extinguisher nozzle and the charged body should not be less than 0.4-0.6m.

Do not touch the body or the fire extinguisher in your hands with live wires or

electrical equipment to prevent electric shocks during firefighting.

Electrical fire extinguishers should use dry powder fire extinguishers,

carbon dioxide, 1211, carbon tetrachloride fire extinguishers or dry sand, etc.

Water and foam fire extinguishers are strictly prohibited.

G: SES Power wrote the last words

The high temperature in summer is not only unbearable, but also affects the

work efficiency of photovoltaic power plants, lithium-ion energy storage

systems, inverters, etc., and even brings many unsafe and uncertain hidden

troubles. We recommend that you try to ensure that the photovoltaic power

station array is not partially shaded, that the inverter and other electrical

equipment are not exposed to sunlight, that the ventilation is good, and that

you closely observe the temperature rise of every important link including the

lithium-ion energy storage system.

If you have questions about clean energy such as photovoltaic power

generation, inverters, lithium-ion energy storage systems, etc., you are welcome

to contact us, and we will serve you sincerely with our nearly 20 years of

experience.