Is lithium iron manganese phosphate battery an upgraded version of lithium

iron phosphate battery? What features does it have?

As a senior practitioner in the lithium battery industry, SES Power has

been paying attention to the development of new lithium-ion batteries. Because

of its excellent safety and low-cost advantages, lithium iron phosphate

batteries have formed advantages over traditional ternary lithium batteries in

many fields, such as electric vehicles, energy storage systems, lead-acid

replacement, and so on. SES Power's products made of square aluminum-shell

lithium iron phosphate cells account for 90% of our total shipments, such as

lead-acid replacement products 12V100Ah, 24V100Ah, 12V200Ah, 3kwh, 5kwh, 10kwh

wall-mounted smart home energy storage systems, racks Type energy storage

system, split combined high-voltage power lithium battery system, polar lithium

battery that can withstand -60 degrees Celsius, starting battery with a starting

current of 2000CCA, customized metal shell lithium iron phosphate battery,

etc.

However, the lithium iron phosphate battery also has its own shortcomings,

such as low energy density ratio, which directly leads to problems such as

excessive volume and excessive weight. Now the lithium battery industry has

launched a new type of lithium iron manganese phosphate battery. Its research

and development and Production is accelerating.

According to reports, many lithium battery companies such as BYD, Gotion

Hi-Tech, and EVE Lithium Energy have indicated that they are researching and

deploying lithium iron manganese phosphate batteries. The reason is very simple.

The energy density of iron-lithium cathode is close to the theoretical extreme

value, and manganese-iron-lithium will become a new growth point for

iron-lithium enterprises: on the basis of both safety and low-cost advantages,

the energy density can be improved.

Before understanding lithium iron manganese phosphate batteries, let's

review the changes in the market structure of lithium iron phosphate batteries

and ternary lithium batteries.

In the initial stage of new energy vehicles, the market share of lithium

iron phosphate in 2014 was 82%. However, due to the higher energy density of

ternary lithium batteries, the market share of lithium iron phosphate batteries

dropped to 32% in 2019, while ternary lithium batteries had a higher energy

density. The installed capacity of lithium batteries reached 62%. In 2020, a

total of 38.9GWh of ternary lithium batteries were installed, accounting for

61.1%; 24.4GWh of lithium iron phosphate batteries were installed, accounting

for 38.3%.

However, the situation will start to change in 2021. On the one hand,

frequent battery spontaneous combustion accidents make consumers have to

re-examine the importance of battery safety. On the other hand, soaring raw

material prices also force auto manufacturers to consider whether to stick to

ternary lithium Battery.

In 2021, the total installed capacity of lithium iron phosphate batteries

will be 79.8GWh, accounting for 51.7%; the installed capacity of ternary lithium

batteries will be 74.3GWh, accounting for 48.1%. In the first six months of

2022, the cumulative loading of lithium iron phosphate batteries reached

64.4GWh, accounting for 58.5%; the cumulative loading of ternary lithium

batteries reached 45.6GWh, accounting for 41.4%. With the expansion of the

market share of lithium iron phosphate batteries, the installed capacity is also

gradually increasing. In the half year of 2022, the installed capacity of

lithium iron phosphate batteries has been close to the installed capacity of the

whole year of 2021, even higher than that of ternary batteries and batteries in

2020. The total installed capacity of lithium iron phosphate batteries is

large.

In fact, the real cost of lithium iron phosphate should be lower than that

of ternary materials, because it does not contain precious metals such as cobalt

and nickel. Although the price of lithium iron phosphate in the market decreased

with the increase of market share, it did not meet expectations. Use a larger

number of cells than ternary lithium batteries.

Lithium Manganese Iron Phosphate (LMFP) batteries are in a sense an

advanced version of Lithium Iron Phosphate (LFP) batteries. It should be

mentioned again here that whether it is a ternary lithium battery or a lithium

iron phosphate battery, it refers to the positive electrode material in the

battery. Musk once made an analogy to the cathode material: the cathode material

can be regarded as a shelf for storing lithium ions. How many lithium ions this

shelf can store determines the energy density of the battery, and the height of

the shelf determines the amount of energy released by the battery.

The "shelf" of lithium iron manganese phosphate has one more "manganese"

than lithium iron phosphate, and manganese is a metal element with very poor

conductivity, which means that the entry and exit of lithium ions in this

"shelf" will not be greatly affected. Therefore, the lithium iron manganese

phosphate battery is guaranteed in terms of safety.

In addition, manganese also has the characteristics of high voltage.

Manganese is added to the cathode material to increase the voltage. Energy

density refers to the energy contained in a unit volume in joules/cubic. Physics

tells us that joules = amperes × volts × seconds, that is, higher voltage means

higher energy density. Generally speaking, manganese-added cathode materials

have higher voltages, such as LMO lithium manganate and NCM nickel cobalt

lithium manganate.

After analysis by SES Power, it is believed that lithium iron manganese

phosphate has 4 advantages as a positive electrode:

1. Lithium iron manganese phosphate has energy density advantages compared

to lithium iron phosphate

The voltage platform of lithium iron manganese phosphate is as high as

3.7~4.1V, which is significantly higher than that of lithium iron phosphate

(about 3.2V). The high-voltage platform can improve the energy density of the

corresponding battery, so the theoretical energy density of lithium manganese

iron phosphate is 15%-20% higher than that of lithium iron phosphate, which can

basically reach the level of ternary battery NCM523, which can provide electric

vehicles with more phosphoric acid. Lithium-iron batteries have higher cruising

range.

2. Lithium iron manganese phosphate has low temperature performance

advantages compared to lithium iron phosphate

The capacity retention rate of lithium iron manganese phosphate can reach

about 75% at -20°C, while the capacity retention rate of lithium iron phosphate

is 60%-70%.

Lithium iron manganese phosphate has safety advantages over ternary

cathodes

3. Compared with ternary, lithium iron manganese phosphate has an olivine

structure, which is more stable during charge and discharge, and has better

safety and cycle stability than ternary.

4. Lithium iron manganese phosphate has a cost advantage

The world is rich in manganese ore resources, and the cost of lithium iron

manganese phosphate is only about 5%-10% higher than that of lithium iron

phosphate. Considering the increase in energy density of lithium iron manganese,

the cost of lithium iron manganese phosphate per watt-hour is slightly lower

than that of lithium iron manganese phosphate per watt-hour. Lithium iron

phosphate, and significantly lower than the ternary battery.

As a firm supporter of lithium iron phosphate batteries, BYD has actually

conducted research on lithium iron manganese phosphate batteries for a long

time. BYD began to explore and upgrade lithium iron manganese phosphate in 2013,

but it was finally rumored that BYD terminated the development of related

technologies in 2016.

CATL also applied for a patent for the preparation method of lithium iron

manganese phosphate as early as 2015. In 2021, CATL will acquire a 15.57% stake

in a lithium iron manganese phosphate material company with an investment of 413

million yuan.

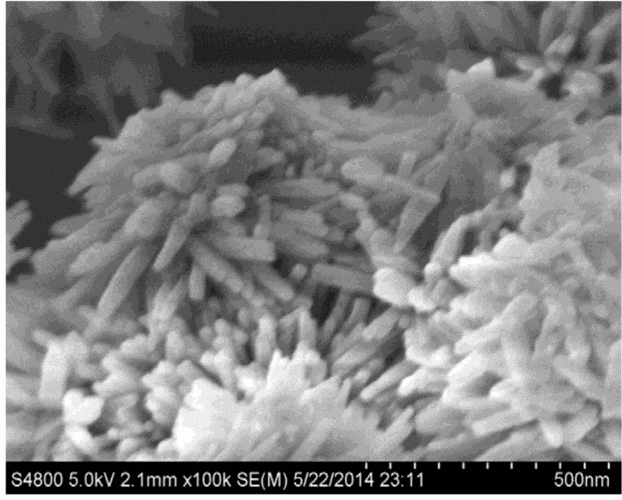

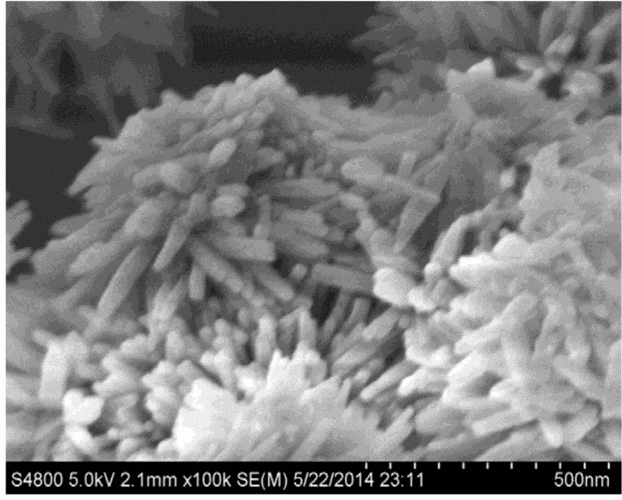

As for the reason why BYD terminated this material, the market speculated

that the processing technology of lithium iron manganese phosphate had

insurmountable difficulties at that time: lithium iron manganese was a

semiconductor, while lithium iron manganese was an insulator, and the particles

of lithium iron manganese were very small, which made the processing technology

route very difficult. It is difficult, and there is currently no unified

technical route in the industry, with high technical barriers.

In terms of production capacity, although LMFP is the evolution of LFP,

because the raw material of manganese is added to LMFP, the entire synthetic

formula needs to be changed, resulting in a huge difference between the entire

production system and LFP. The LMFP production line is difficult to obtain by

transforming the LFP production line, and a new production line still needs to

be built. This investment is huge.

Therefore, even if there is a good improvement in performance, the

input-output ratio is very different, and the marginal economic benefits that

high R&D costs can bring to raw material companies are limited, which may be

the biggest reason for restricting companies to make in-depth investments.

Some companies have begun to consider applying lithium iron manganese

phosphate to the field of energy storage. With its high energy density, high

safety, wide temperature range and low cost, it can expand the application

scenarios of energy storage and accelerate the development of the energy storage

market.

Although there are still various problems, SES Power is still optimistic

about this technical route. Because when the potential of lithium iron phosphate

batteries has been tapped almost and is close to the theoretical extreme value,

updating electrode materials is indeed a conventional upgrade route. However,

consumers are not only concerned about the safety and theoretical capacity of

the battery, but also the charging speed and the actual mileage. And this also

means that it's not enough to just focus on cathode materials. SES Power

believes that it is actually more efficient to prioritize the development of

production processes, such as solid-state batteries. The biggest difference

between solid-state batteries and traditional lithium batteries is the use of

solid electrolytes instead of traditional electrolytes.

Therefore, the comprehensive upgrade of lithium batteries will not only

stop at the positive electrode, but the upgrade of other components and

manufacturing processes will also bring more space for the future of lithium

batteries.