After continuous promotion and warm-up, the CTP3.0 lithium battery of CATL,

the Kirin battery, was officially unveiled a few days ago. SES Power has always

used CATL products, so we are also quite concerned about the performance of this

battery.

255Wh/kg system energy density, 72% volume utilization rate, 1,000 km

battery life, and 4C fast charging performance, these parameters have broken

through the performance of existing battery indicators, causing concern among

peers and customers. It is worth noting that the CATL seems to have explained a

lot in terms of battery life, energy density, volume utilization, fast charging,

safety and other dimensions, but on closer inspection, the CATL may be based on

confidentiality and did not explain the details very much. Thorough: For

example, the system energy density can reach 255Wh/kg of high nickel ternary

battery, how much has the single energy density achieved? Is the cost of CTP3.0

lower than that of 1.0 and 2.0, or is it increased with the increase in energy

density?

A: Is the semi-solid battery of the CATL approaching mass production?

Under the ternary material system, the CTP3.0 lithium battery achieves an

energy density of 255Wh/kg for the entire lithium battery system, which is a

very good performance. Behind it, the energy density of the single cell must

play an important role. The energy density of the CATLCTP1.0 lithium iron

phosphate system battery system is only about 140Wh/kg.

If the CTP3.0 is loaded with a lithium iron phosphate system battery, the

energy density is only 160Wh/kg, an increase of about 14%. However, the energy

density of the ternary battery system has increased from 180Wh/kg in the first

generation to 255Wh/kg, an increase of about 41.67%. Obviously, this cannot be

achieved only by optimizing the system structure, and behind it must be a

substantial improvement of the monomer material system.

However, the CATL did not disclose the energy density of the ternary

battery behind it. We can only make the following rough calculations:

1. Refer to the volume utilization rate of 72% (the actual proportion of

cells in the battery pack) to infer the energy density of its single cell. There

will be a certain gap in this calculation method, but the difference will not be

too large. After all, the main component of the entire battery pack is the

battery cell, and the other components are mainly structural parts, circuits,

BMS and components. If calculated according to the 72% volume utilization rate,

the energy density of the CTP3.0 ternary battery can reach 355Wh/kg.

2. Roughly calculated according to its lithium iron phosphate battery

group. It is understood that the energy density of CATL lithium iron phosphate

battery is already around 200Wh/kg, the energy density of CTP3.0 lithium iron

phosphate system is 160Wh/kg, and its group efficiency is estimated to reach

80%. And according to the calculation of 80%, the energy density of the ternary

battery is about 318.75Wh/kg (in fact, the group efficiency of 80% is already

the industry-leading level).

SES Power believes that the ternary system of CTP3.0 is designed to be more

complex than the lithium iron phosphate system due to the safety protection of

high energy density. In this case, its actual grouping efficiency may not be as

high as that of the lithium iron phosphate system. If true, then its ternary

cell energy density is expected to be around 350Wh/kg. There is another

possibility: the ternary battery loaded by CTP3.0 is a semi-solid battery

developed by CATL.

The energy density of the single semi-solid lithium battery developed by

Gotion is as high as 360Wh/kg, and the system energy density reaches 260Wh/kg.

For comparison, assuming that the group efficiency of CATL is a few percentage

points higher, then its ternary battery with a system energy density of 255Wh/kg

is expected to have a single energy density of more than 330Wh/kg, and the high

probability of achieving this energy density is also the same. Semi-solid

battery.

As a leader in power batteries, CATL is at the forefront in the research

and development of semi-solid batteries, all-solid-state batteries, condensed

matter batteries, sodium-ion batteries and other material systems, so its

semi-solid state will be mature and mass-produced next year. Not

surprisingly.

B: CTP3.0 lithium batteries may currently be "more expensive"

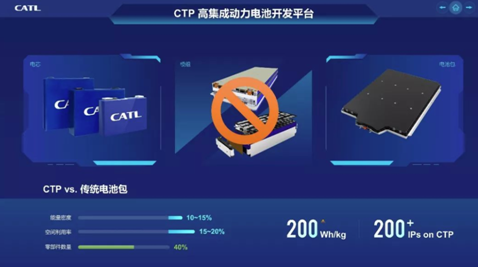

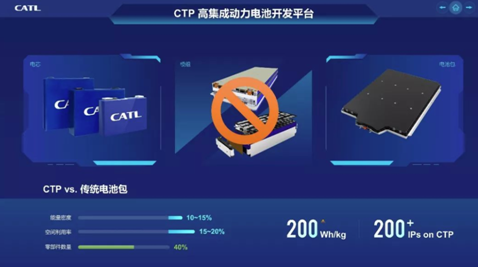

In 2019, when CATL launched the first-generation CTP battery system, it

said, "The volume utilization rate of CTP battery packs has increased by

15%-20%, the number of components has been reduced by 40%, and the production

efficiency has increased by 50%, which will be greatly reduced after being put

into application. The manufacturing cost of the power battery.”

However, in the release content of CTP3.0 battery, CATL did not mention the

cost, which also made the cost of CTP3.0 battery compared with the first and

second generation a mystery. Maybe only car companies know it, but we You can

also speculate on the basis of market conditions.

On the one hand, CATL Times said that with a 255Wh/kg CTP3.0 battery pack,

the vehicle can last for 1,000 kilometers. We can basically infer that this

battery pack is mainly used for mid-to-high-end models. Therefore, with a system

energy density of 255Wh/kg and a model with a range of 1000km, this battery

should not be cheap at present. On the other hand, if it is a semi-solid

battery, it will be more expensive than the current mainstream battery at this

stage, because it involves the upgrade of a series of materials such as positive

electrode, negative electrode, electrolyte, and separator, which are all new

materials and new systems. cost increase.

However, CTP3.0 uses lithium iron phosphate battery packs, and it is

expected that the cost may have certain advantages compared to the first and

second generations.

C: Volume utilization rate hit a new high

In terms of battery pack volume utilization, this time CATL directly

compares the recently popular 4680. According to CATL, the volume utilization

rate of the CTP3.0 battery pack has reached a new high, reaching 72%, which is

higher than the 63% utilization rate of the 4680.

In terms of improving the volume utilization rate, the CATL adopted "cell

inversion, which makes the cell space utilization rate reach 72%". According to

the introduction of CATL, it is its accurate calculation and AI simulation to

explore the design boundary of the CTP3.0 battery life cycle application

scenario.

Through the cell inversion and the original bottom space sharing scheme,

the functional modules such as structural protection, high-voltage connection,

thermal runaway exhaust and other functional modules are intelligently

distributed, releasing 6% of the energy space. In fact, as a battery pack, this

volume utilization rate is indeed remarkable.

A month ago, BYD released the CTB technology with higher integration of the

whole vehicle and battery. According to BYD's introduction, the current volume

utilization rate of its CTB battery system is only 66%. It can be seen that one

is 63% volume utilization rate of 4680 battery, the other is 66% volume

utilization rate in CTB form, and CTP3.0 battery achieves 72% volume utilization

rate in CTP structure, a difference of several percentage points, which requires

a lot of innovative design and verification behind it.

SES Power uses CATL cells in many lithium battery products, such as

12V100Ah, 12V200Ah, 24V100Ah, 36V100Ah, 48V100Ah, household energy storage 3KW,

5KW systems, rack-mounted energy storage systems and other products. We believe

that CTP3.0 is different from the previous two generations. CATL also named it

"Kirin battery" (the previous two generations did not have a Chinese name),

which shows that CATL aims to make it a benchmarking competition. Power

products. In the context of technological iterations that you are catching up

with, competition including battery system energy density, safety, fast

charging, heat dissipation, and volume utilization is still fierce. Whether CATL

can rely on "Kirin" to defend its technological advantages, we still need to

Wait and see.