Lithium-ion batteries (LIBs) have become the main energy storage solutions

in modern social life. Among them, lithium iron phosphate battery perfectly

replaces lead-acid battery, and is the first choice for grid-connected peak

regulation, off-grid energy storage, photovoltaic energy storage, UPS system,

data center and other industries.

Although SES Power has been focusing on the application of lithium iron

phosphate batteries in the past ten years, we still have many products that use

3.7V lithium cobalt oxide batteries and ternary lithium batteries, and the

brands used are Panasonic, Sanyo, Samsung, LG, BAK and other international

famous brands, such as our AGV batteries, home electronics batteries, personal

care products batteries and so on.

The ternary lithium battery is very popular in the market because of its

high energy density and suitable price, and SES Power also pays attention to its

development. For lithium batteries, the decisive factor is actually the

development of the positive electrode material of the battery. Now let's briefly

talk about the development trend of cathode materials for ternary lithium

batteries on the market.

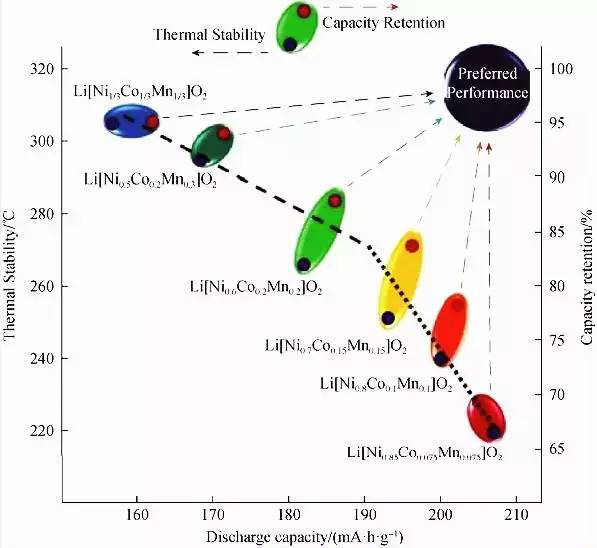

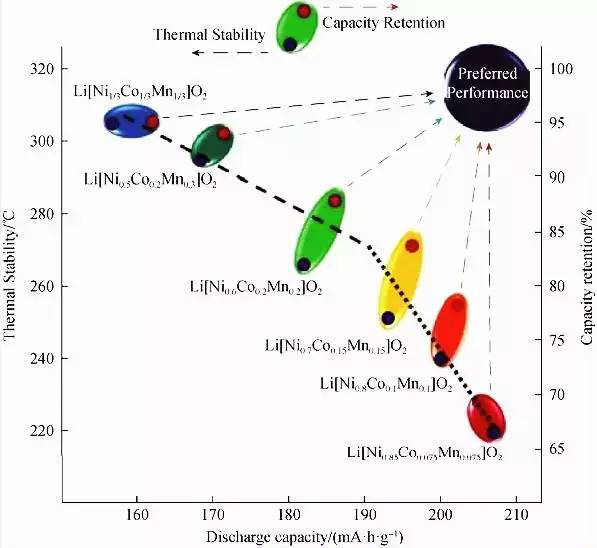

1: High nickel ternary material

Nickel-Cobalt-Manganese has the characteristics of high specific capacity,

long cycle life, low toxicity and cheapness. In addition, the three elements

have good synergistic effect, so they have been widely used.

In redox energy storage, nickel is the main component. How to effectively

increase the specific capacity of the material by increasing the content of

nickel in the material is one of the current research hotspots.

Generally speaking, high-nickel ternary cathode material means that the

mole fraction of nickel in the material is greater than 0.6. Such a ternary

material has the characteristics of high specific capacity and low cost, but

also has low capacity retention rate, poor thermal stability, etc. defect.

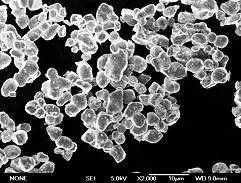

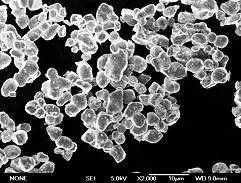

The material properties can be effectively improved through the improvement

of the preparation process. The micro-nano size and morphological structure of

the particles determine the performance of the high-nickel ternary cathode

material to a large extent. Therefore, the main preparation method at present is

to uniformly disperse different raw materials and obtain nano-spherical

particles with large specific surface area through different growth

mechanisms.

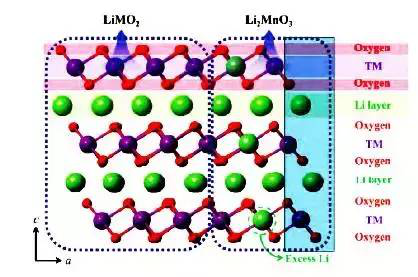

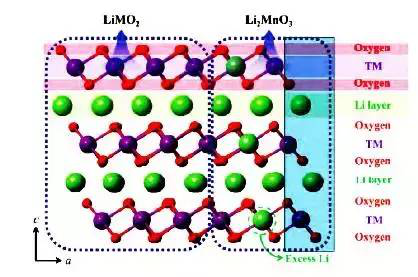

2: Lithium-rich ternary material

The figure below is a schematic diagram of the structure of the

lithium-rich ternary cathode material xLi2MnO3·(1-x)LiMn1/3Ni1/3Co1/3O2

(0.1≤x≤0.5). Due to its special structure, more lithium can be extracted and it

has a wide voltage The advantages of window and high energy density ratio have

been favored by researchers in recent years.

All of this material is characterized by high voltage, and the first

charge-discharge mechanism is different from the subsequent charge: the first

charge causes structural changes! This change is reflected in the charging curve

with two different plateaus demarcated by 4.4 V. During the second charging

process, the charging curve is different from that of the first one, because

Li2O is removed from the layer during the first charging process. The structure

of Li2MnO3 is irreversibly extracted, and the plateau disappears at around

4.5V.

Lithium-rich ternary materials show good application prospects and are one

of the key materials required for next-generation high-capacity lithium-ion

batteries, but research continues for large-scale applications. The material has

the following practical problems that urgently need to be solved by industry

researchers:

(1) Insufficient understanding of the mechanism of lithium extraction and

intercalation, unable to explain the phenomenon that the coulombic efficiency of

materials will be low and the material properties will vary greatly;

(2) The research on doping elements is not sufficient and relatively

single;

(3) Poor cycle stability due to the corrosion of the positive electrode

material by the electrolyte at high voltage;

(4) There are few commercial applications, and the investigation on safety

performance is not comprehensive enough.

3: Single crystal ternary cathode material

The single-crystal high-voltage ternary material can improve the lithium

ion transfer efficiency and reduce the side reaction between the material and

the electrolyte, thereby improving the cycle performance of the material under

high voltage.

This material is a ternary cathode composite material with excellent

electrochemical properties and a good layered structure. At 3-4.4 V, the 0.1

discharge specific capacity of the coin cell battery can reach 186.7 mAh/g, and

the discharge specific capacity of the full battery after 1300 cycles is still

98% of the initial discharge capacity.

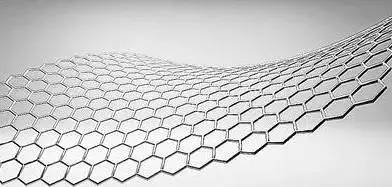

4: Graphene doping

Graphene has a two-dimensional structure with a single-layer atomic

thickness, which is structurally stable and has an electrical conductivity of up

to 1×106 S/m. The use of graphene in lithium-ion batteries has the following

advantages: ① good electrical and thermal conductivity, which helps to improve

the rate performance and safety of the battery; ② compared with graphite,

graphene has more lithium storage space, which can improve the energy density of

the battery; ③ The particle size is in the micro-nano scale, and the diffusion

path of lithium ions is short, which is beneficial to improve the power

performance of the battery.

5: High Voltage Electrolyte

Ternary materials have received more and more attention and research due to

their high voltage windows. However, due to the low electrochemical stability

window of the current commercial carbonate-based electrolytes, high-voltage

cathode materials have not yet been industrialized.

When the battery voltage reaches about 4.5V, the electrolyte begins to

undergo violent oxidative decomposition, which leads to the failure of the

lithium intercalation and delithiation reaction of the battery to proceed

normally. Improving the stability of the electrode/electrolyte interface by

developing and applying new high-voltage electrolyte systems or high-voltage

film-forming additives is an effective way to develop high-voltage

electrolytes.

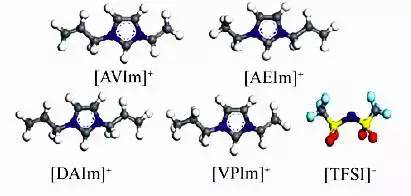

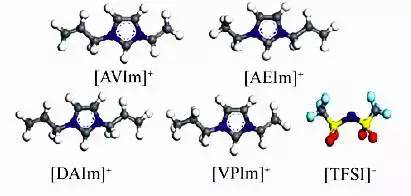

In energy storage systems, ionic liquids, dinitrile organic compounds and

sulfone organic solvents are currently used as electrolytes for high-voltage

ternary materials. Ionic liquids with low melting point, non-flammability, low

vapor pressure, and high ionic conductivity exhibit excellent electrochemical

stability and have been extensively studied.

6: Plasma synthesis method

When using the traditional high-temperature calcination method to prepare

the ternary cathode material, the required synthesis temperature is high, the

calcination time is long, and the energy loss is large.

The study found that in the low temperature plasma environment, the

chemical activity of each reactant is high and the chemical reaction speed is

fast, which can realize the rapid preparation of ternary cathode materials. The

oxides of nickel cobalt manganese and lithium carbonate are mixed uniformly, and

then placed in a plasma generator, under the condition of introducing oxygen,

and reacting at 600 ° C for 20 to 60 minutes to obtain a ternary cathode

material Li (Ni1/3Co1/3Mn1 /3) O2.

7: Preparation of ternary cathode materials from waste batteries

The cost of cathode materials for lithium-ion batteries accounts for

30%-40%. Therefore, the energy storage performance of cathode materials can be

recovered by recycling the cathode materials of waste batteries and the

preparation process, which can greatly reduce the cost of lithium-ion batteries,

and a complete the lithium-ion battery industry chain should include the

recycling of lithium-ion batteries.