There is still a huge market for lead-acid batteries with many

shortcomings. Can lithium batteries completely replace them?

The lead-acid battery was the first rechargeable battery invented in the

world. Despite intense competition from various new technologies, lead-acid

batteries still accounted for 48% of total global battery sales (up to $37.5

billion) as of 2018. Although SES Power focuses on lithium battery applications,

many of our products using lithium iron phosphate batteries are usually used to

replace lead-acid batteries, so we still pay attention to the development of

lead-acid batteries.

Vehicle applications account for approximately 75% of current lead-acid

applications (by energy storage capacity). Of course, lead-acid batteries are

also used in stationary energy storage applications, but are mainly used in

user-side energy storage systems. It accounted for about 4.5% of the total

electrochemical energy storage capacity deployed globally in 2017. In the U.S.,

only 1% of lead-acid batteries are used to deploy battery energy storage (most

of which were deployed between 2003 and 2018). In 2018, lead-acid batteries

accounted for 27% of the total installed capacity of China's battery energy

storage systems, but this share fell to 14% in 2019, as the market share of

lead-acid batteries was seized due to the rapid decline in the cost of

lithium-ion batteries.

Lead-acid batteries are a highly mature battery technology with well-known

advantages and disadvantages. Both the positive and negative electrodes are

lead-based, and the sulfuric acid electrolyte (pH < 2) provides sulfate ions

for battery reactions. In the discharge state, both electrodes contain lead

sulfate (PbSO4), while in the charged state, the positive electrode is oxidized

to lead oxide (PbO2) and the negative electrode is reduced to metallic lead

(Pb). The specific energy of lead-acid batteries is low (30-40Wh/kg), while the

specific energy of lithium-ion batteries is high (150-200Wh/kg), but this

indicator is less important for stationary batteries. The charge-discharge

round-trip rate is quite high, ranging from 79% to 86%. Lead-acid batteries cost

less than lithium-ion batteries and are simpler to manufacture. The installed

cost of a lead-acid battery with a duration of 4 hours is estimated at

$260-290/kWh, which is very close to the installed cost of a lithium-ion battery

($275-290/kWh).

Both lead-acid and sodium-sulfur batteries have been largely replaced by

lithium-ion batteries. The installation cost of lead-acid batteries is similar

to that of lithium-ion batteries, but the cycle life and calendar life are

shorter than lithium-ion batteries. But in terms of recycling, lead-acid

batteries are indeed more mature and perfect than lithium batteries. Lead-acid

batteries have a mature supply chain and higher recycling rates (>99% in the

US and Europe). Since they use an aqueous electrolyte, they are arguably safer

than lithium-ion batteries.

The main reason why lead-acid batteries are currently being surpassed by

lithium-ion batteries in most regions is the short cycle life. Lead-acid

batteries lead to continuous loss of electrode material during operation,

coupled with side reactions such as water electrolysis, acid stratification, and

accumulation of water-impermeable sulfates on electrodes, which ultimately lead

to shorter cycle life of lead-acid batteries.

After more than a century of development, some of these problems have been

solved by improving electrode formulations, battery design, and fabrication

methods. Nonetheless, when the charge-discharge cycle is performed at 80% of the

discharge depth, the charge-discharge cycle life of the lead-acid battery will

be shortened, in theory, about 500 to 1,000 cycles, while the lithium-ion

battery cycled to the same depth of discharge is 1,000 to 3,000 cycles, not to

mention lithium iron phosphate batteries with a cycle life of 4,000 cycles.

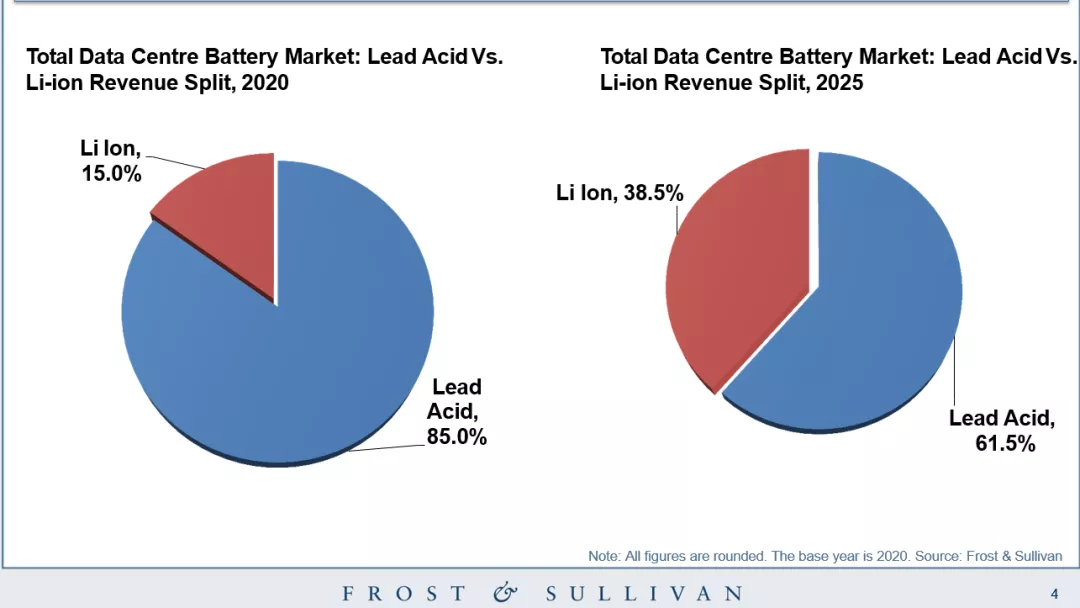

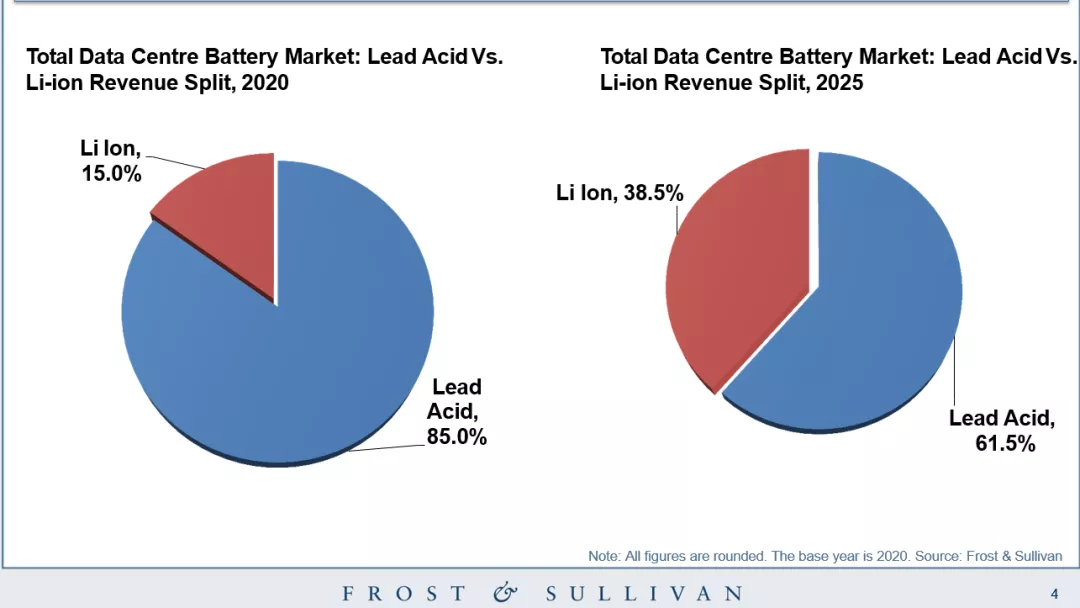

Frost & Sullivan, a global authoritative consulting agency, believes

that in 2020, lithium-ion batteries will account for 15% of the global data

center battery market, but with the increasing application of lithium-ion

batteries in data centers, it is expected that by 2025, this proportion will be

significantly rose to 38.5%.

Lithium battery usage in data centers (Source: Frost & Sullivan)

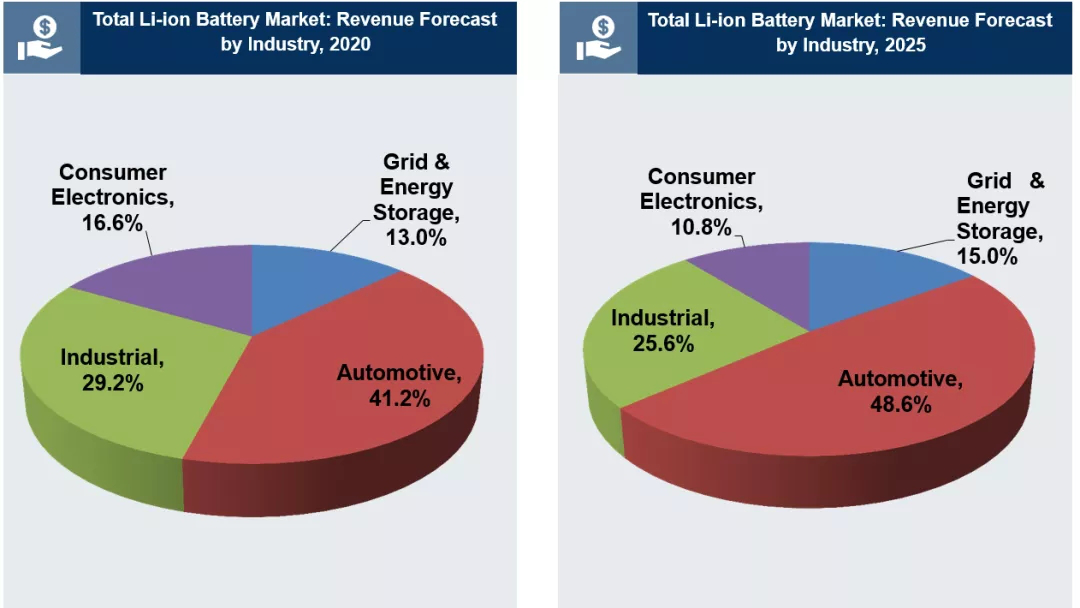

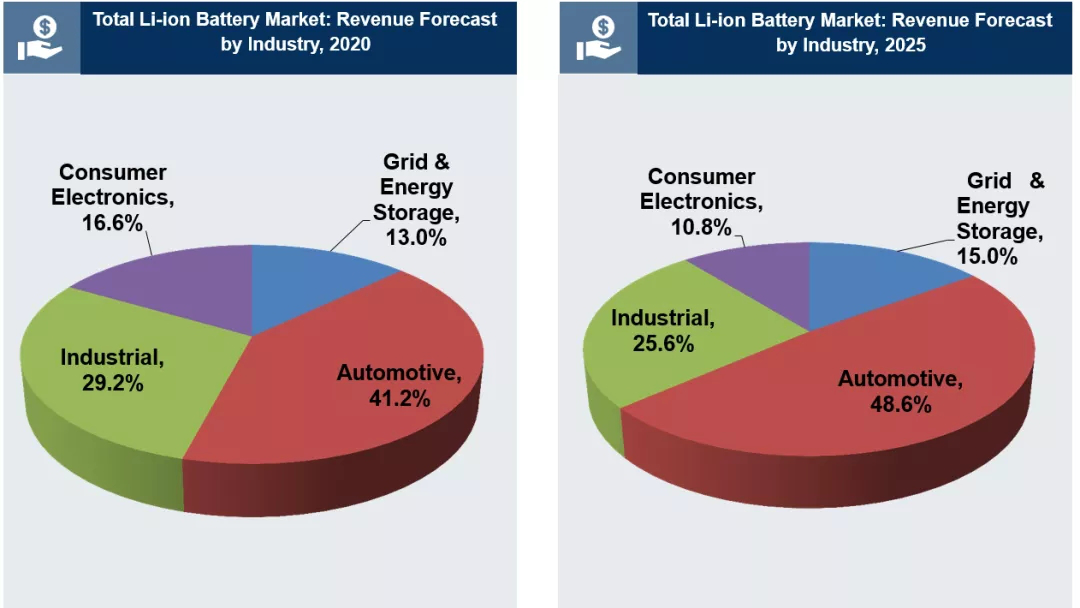

Data center segments including industrial, grid and energy storage,

automotive and consumer electronics will increasingly use lithium-ion batteries.

The overall contribution of energy storage applications to the total market is

expected to increase from 13% in 2020 to 15% in 2025.

Status and Trends of Use in Various Industries (Source: Frost &

Sullivan)

In grid-scale energy storage applications, lithium-ion batteries provide

higher energy output per cycle, and as technology advances, the cycle life of

lithium-ion batteries will continue to increase. In addition, the installed cost

gap between the two is expected to narrow in the coming years, mainly as the

cost of lithium-ion batteries continues to decline while the cost of lead-acid

batteries stagnates.

Developing countries may provide an exception to this trend – in these

cases, lead-acid batteries can cost twice as much as lithium-ion batteries, and

lead-acid batteries are expected to continue to play a major role in the

stationary energy storage industry, at least continuously by 2030.

Of course, this is not without solutions. SES Power believes that the

lithium iron phosphate batteries eliminated from pure electric vehicles can

still be used for a long time and can meet the needs of energy storage systems.

Therefore, many batteries eliminated from pure electric vehicles are directly

transformed into It has become an energy storage system, which can greatly

reduce the cost of the energy storage system.

Using retired lithium iron phosphate batteries, SES power has successfully

reduced the price of 12V100Ah, 12V200Ah, 24V100Ah, 36V100Ah, 48V100Ah, home

energy storage 3KW, 5KW systems, rack-mounted energy storage systems and other

products to close to lead-acid, but the performance is Double or even triple the

lead acid.