Lithium-ion battery thermal stability and safety analysis of overcharge,

high temperature and short circuit

In recent years, reports of fires and even explosions caused by lithium-ion

batteries are not uncommon.

Lithium-ion batteries have strong dangers, especially in the case of abuse,

safety issues are more prominent.

1. Thermal stability analysis of lithium-ion battery materials

The fire hazard of lithium-ion batteries is mainly determined by the amount

of heat generated by chemical reactions in various parts of the battery. In the

final analysis, the fire hazard of lithium-ion batteries depends on the thermal

stability of the battery material, and the thermal stability of the battery

material depends on the chemical reactions that occur between its internal

parts.

1) Influencing factors of the thermal stability of anode materials

The onset temperature of the negative electrode material's heat generation

increases with the increase of the particle size.

2) Factors affecting the thermal stability of cathode materials

The initial temperature of the reaction between the positive electrode

material and the electrolyte increases as the stoichiometric number

decreases.

The higher the content of Ni in the cathode material, the more unstable it

is, and the higher the content of Mn, the more stable it is.

3) Influencing factors of electrolyte thermal stability

The organic solvent DMC is an important factor causing the instability of

the electrolyte, and the higher the DMC content, the more unstable the

electrolyte.

The electrolyte can make the positive electrode react at a lower

temperature, and different solvents and lithium salts in the electrolyte are

suitable for different positive electrode materials.

2. Safety analysis of lithium-ion battery abuse

The safety of lithium-ion batteries mainly depends on the thermal stability

of battery materials, and is also closely related to abuse conditions such as

battery overcharge, needle stick, extrusion, and high temperature.

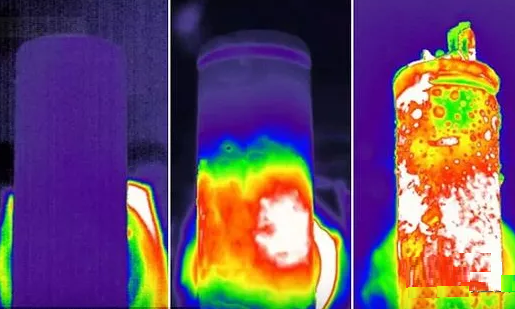

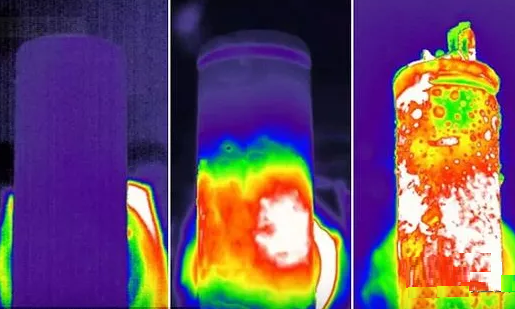

1) Overcharge

The overcharge test simulates the potential safety hazards of the battery

when there is an error in the charger voltage detection, the charger fails or

the wrong charger is used.

The thermal runaway caused by overcharging may come from two aspects: on

the one hand, the Joule heat generated by the current, and on the other hand,

the reaction heat generated by the side reactions of the positive and negative

electrodes. When the battery is overcharged, the negative electrode voltage

gradually increases, and the process of delithiation becomes more and more

difficult. This causes the internal resistance of the battery to increase

sharply, and therefore generates a large amount of Joule heat, which is more

obvious when charging at a high rate. The positive electrode oxidant in the

overcharged state releases a lot of heat, and the negative electrode also reacts

exothermically with the electrolyte. When the rate of heat release is greater

than the rate of heat dissipation of the battery, and the temperature rises to a

certain level, thermal runaway will occur.

2) High temperature

The simulated environment high temperature test can be carried out by using

the hot box test. The hot box test simulates the improper use of the battery at

a high temperature, such as placing a mobile phone in an exposed car, or putting

a mobile phone or electronic product in a microwave oven, and the temperature

can reach 130°C or even 150°C. In the case of thermal abuse, the heat source is

not only from the positive and negative electrode materials inside the battery

and its reaction with the electrolyte, the separator film melts and shrinks at

high temperatures, resulting in a short circuit between the positive and

negative electrodes. The Joule heat generated by the short circuit is also an

important heat source during the hot box test. .

3) Short circuit

The short circuit of the battery is divided into external short circuit and

internal short circuit.

External short circuit generally refers to the short circuit caused by the

direct contact between the positive and negative electrodes; internal short

circuit refers to the short circuit in the area where the battery is affected by

foreign objects when the battery is punctured by a sharp object or is impacted

or squeezed.

The safety research of internal short circuit generally adopts methods such

as acupuncture, extrusion, etc. The purpose is to simulate the situation of the

battery being punctured, collided, and squeezed by foreign objects. Acupuncture

causes a short circuit of the battery at the acupuncture point. The

short-circuit area forms a local hot zone due to a large amount of Joule heat.

When the temperature of the hot zone exceeds the critical point, it will cause

thermal runaway, causing smoke, fire or even explosion hazards. Extrusion is

similar to acupuncture, both of which cause local internal short circuits and

may cause thermal runaway. The difference is that squeezing does not necessarily

cause damage to the battery casing. If the casing is not damaged, it means that

flammable electrolyte will not leak from the hot zone, and the heat dissipation

effect from the hot zone is worse.

It is often much more difficult to test the local internal short circuit of

the battery caused by squeezing and needle sticking than the external short

circuit test. This is because the internal heat of the battery tends to be

uniform when the battery is externally short-circuited, and the Joule heat

generated by the external short-circuit battery will not Directly trigger the

thermal runaway reaction of the battery.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate battery is a perfect

replacement for lead-acid batteries, and it is the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.