Lithium batteries are advancing by leaps and bounds in the automotive

field, but they are now facing two major problems

As of January 2021, among the regions and companies that have announced

plans to produce batteries by 2025, the European market has announced a battery

production of 652GWh: Korean companies have set a target of 193GWh, European

companies have set a target of 161GWh, Chinese companies have set a target of

48GWh, and Tesla has 250GWh. At that time, the required capacity of the market

was 400GWh, which was at an oversupply level.

However, many changes have taken place from January to now. Automakers are

scrambling to formulate a road map for the transition to electric vehicles, and

one after another announces the time to achieve the goal of carbon neutrality.

In the current climate, the market share of pure electric vehicles may exceed

50% after 2030.

In this context, there will be changes in European and American policies in

July and August 2021. The European Commission has decided to reduce greenhouse

gas emissions by 55% by 2030, and ban the sale of diesel locomotives, including

hybrid vehicles, by 2035. A new "Border Carbon Tax" will be established in 2023,

called the Border Carbon Adjustment Measures (CBAM). It also aims to reduce

carbon dioxide emissions in all sectors by 55% by 2030 compared to 1990. This is

an improvement from the 40% target set in 2019.

In August, the United States issued an executive order specifying that more

than 50% of new vehicles (passenger cars and light trucks) sold by 2030 are

electric vehicles, plug-in hybrid vehicles (PHEV) and fuel cell vehicles (FCV).

Hybrid electric vehicles are not included. The impact of these policy changes on

the United States is far greater than the impact of European regulations. China

is accelerating the transition to pure electric vehicles, plug-in hybrid

electric vehicles and hydrogen fuel cell electric vehicles.

At the same time, people's interest in lithium batteries, the energy source

for battery electric vehicles, is receiving attention. The first is that the

price of battery cells has soared due to the increase in raw material prices,

and the second is about safety, such as the increasing number of fire cases.

This happened in China, which has been leading the battery electric vehicle

market. Last month, due to the increase in lithium production costs, BYD

announced that it would increase battery prices by 20%. Compared with December

2020, the price of lithium cobalt oxide, which is the core of the production of

electric vehicle batteries, has more than doubled, and the price of electrolyte

has risen by more than 150%.

In May, the International Energy Agency (IEA) predicted that by 2030, the

global supply of lithium and cobalt will only meet half of the projected demand.

Copper production can be reduced by 25% compared to the consumption level.

Bloomberg New Energy Finance predicts that by the end of this year, global

lithium consumption will increase fivefold.

Among them, the competition of nickel and cobalt, which are the main

materials of NMC (nickel manganese cobalt) and NCA (nickel cobalt aluminum), is

intensifying, and concerns about price increases are also intensifying.

Especially cobalt faces severe challenges. Although nickel is a relatively

abundant resource, there are also predictions that starting from 2030, nickel

will become scarce. To this end, some companies have implemented strategies to

distinguish raw materials used in low-end and high-performance high-end

cars.

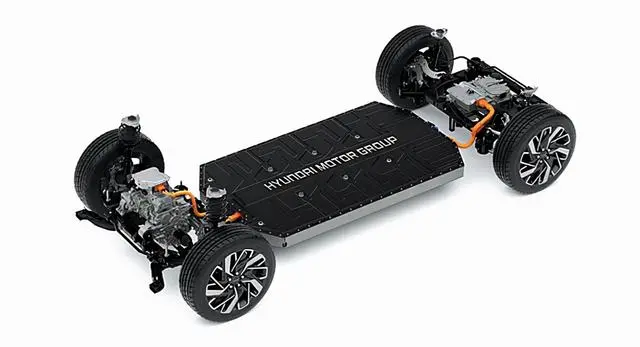

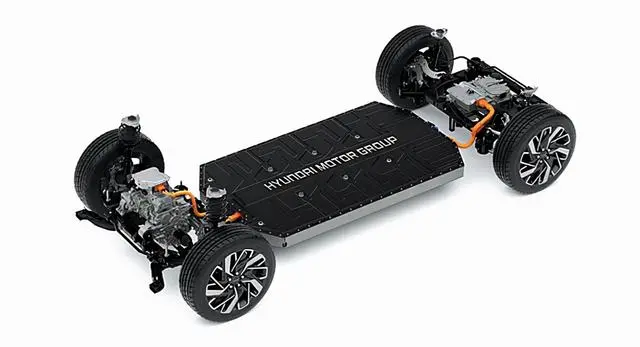

Secondly, it involves safety, such as fire. LG Energy Solutions has paid a

huge amount of compensation due to the recalls of Hyundai Motor and General

Motors. The fire accident caused by the instability of the LG battery diaphragm

also makes the all-solid-state battery the object of research again.

In particular, there are more than 300 million electric bicycles (scooters)

in China, and there were 10,300 fires from January to September this year. About

80% of accidents occur when the battery is charging, most of which are caused by

the fire of the lithium battery. As with car batteries, the number of fire

accidents during charging is very high. Although lithium batteries have high

energy density, the high flammability of the electrolyte is an important fire

factor.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate battery is a perfect

replacement for lead-acid batteries, and it is the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.