According to reports, two trucks loaded with battery production equipment

drove into the inventory area of Tesla's Texas Gigafactory, marked as

"Positive Production Line 1" and "Negative Production Line 1" respectively. The

signal released by this move is that Tesla has begun to install 4680 production

line equipment and is preparing for trial production of 4680 batteries.

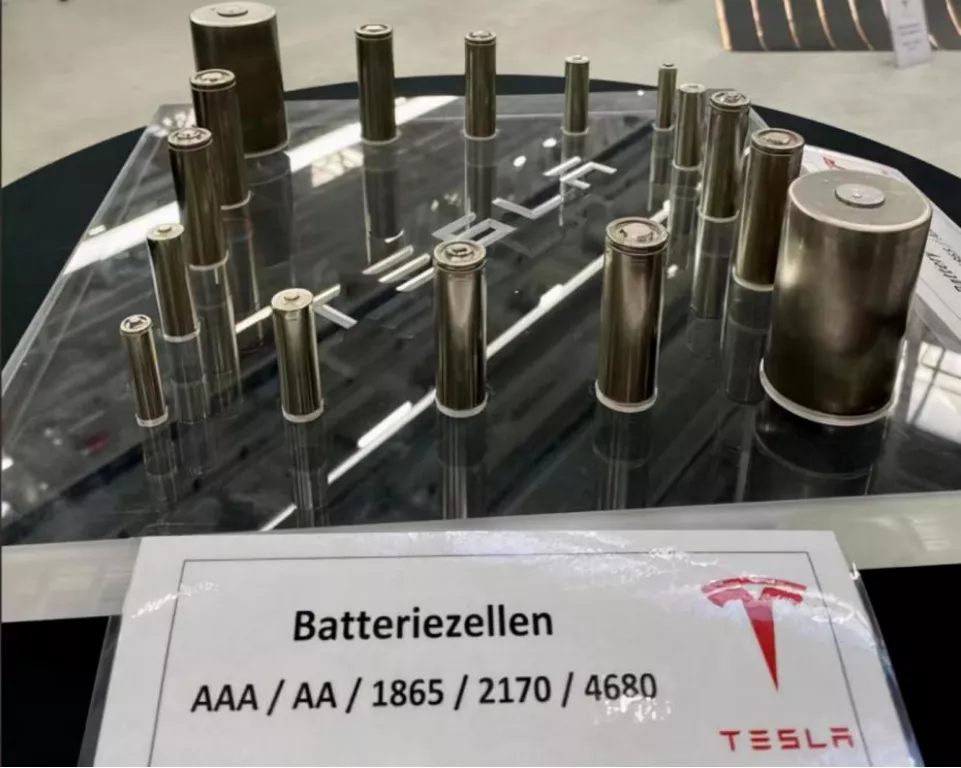

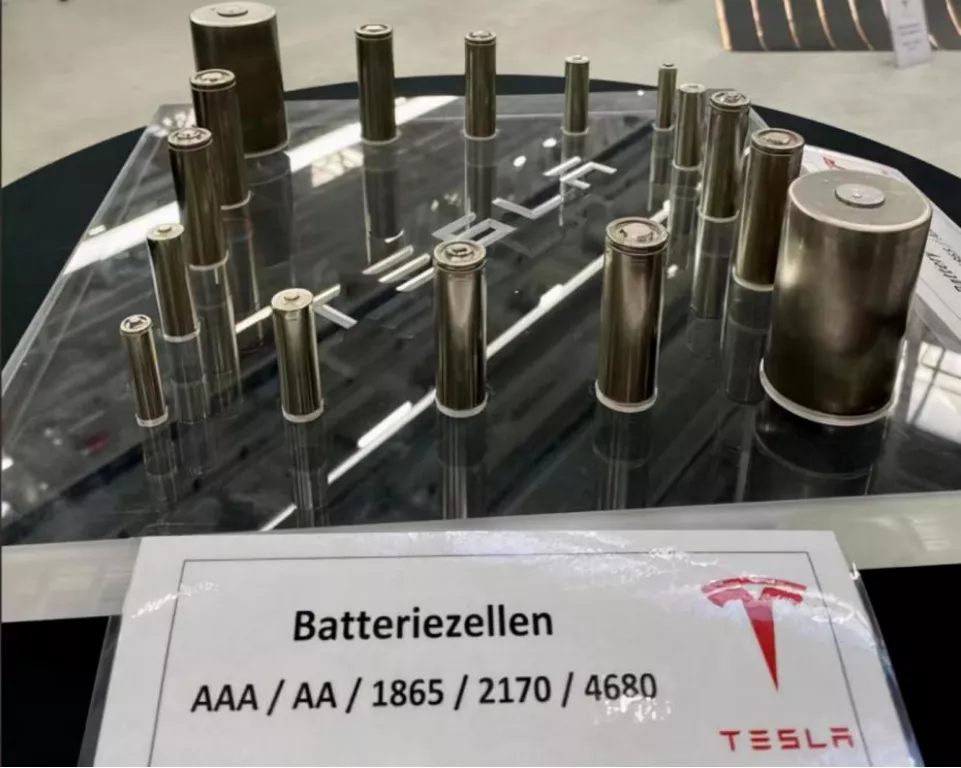

This battery with a diameter of 46mm and a height of 80mm was first

announced on Tesla Battery Day last September. The single energy density can be

increased by 5 times to 300Wh/kg, and the charging and discharging efficiency is

6 times higher than that of a battery with tabs. Mounted on the vehicle can

increase the cruising range by 16% and reduce the cost of electricity by

56%.

In September, Tesla's Berlin factory broke ground, mainly producing 4680

batteries. Musk said that he hopes the Berlin plant will produce 5,000 Model Y

with 4680 batteries per week by the end of 2022, ideally 10,000 vehicles per

week.

In addition, Tesla’s pilot plant in Kato Road, Fremont, USA is also

accelerating the production of 4680 batteries, with an estimated annual

production capacity of 10GWh. With the relocation of Tesla's headquarters to

Texas, the Texas plant will also produce 4680 batteries, which is expected to be

mass-produced in 2022.

It is reported that the current trial production line yield rate of Tesla

4680 batteries has increased from 20% last year to 70%-80%. At the recent Q3

exchange meeting, Tesla also confirmed that the first batch of cars equipped

with the new 4680 battery will be delivered next year.

Tesla's plan is to provide early-stage batteries for the first batch of

cars at the Fremont pilot plant, after which it will soon need battery partners

and new production facilities in Berlin and Texas to support greater

production.

According to news at the end of August, in addition to Panasonic, which is

already cooperating, Tesla has begun to look for other 4680 large cylindrical

battery manufacturers, including CATL, LG Chem, Eve Lithium and so on.

Competing for 4680 battery orders, including Panasonic, LG New Energy,

Samsung SDI, CATL, Eve Lithium Energy, BAK Battery, Honeycomb Energy and other

Chinese, Japanese and Korean battery companies have set foot in the development

of the Big Cylinder/4680 battery cell and speed up the follow-up 4680 battery

layout.

We can summarize some information:

1. Centralized mass production in 2022-2024

According to the currently announced plan, Tesla will take the lead in mass

production in 2022, and it is expected that the first batch of batteries will be

mounted on Model Y; Panasonic will start trial production in March 2022; LG New

Energy’s goal is to complete the trial before Panasonic starts mass production.

The production line is planned to be mass-produced in 2023 at the earliest; BAK

has begun planning a mass production base for large-size cylindrical batteries,

which is expected to be mass-produced in the next two years; Eve Lithium Energy

and StoreDot are jointly developed and planned to be mass-produced in 2024.

2. Breakthrough fast charging performance

Due to the larger size of the battery cell, the more the battery cell

generates heat and the harder it is to dissipate heat due to the presence of

resistance, which in turn affects the charging speed. The Tesla 4680 battery

cell adopts the all-pole lug solution, and the metal sheet is directly connected

with the battery pole lug, and the contact area is larger. For breakthroughs in

welding processes and materials, no more details have been announced.

Through technical optimization of the structural design, impedance can be

greatly reduced, and the fast-charging performance can be 3 times higher than

that of conventional monopolar ear cells; Israeli start-up company StoreDot has

produced the first 4680 cells that can be fully charged in just 10 minutes.

3. CTC technology achieves cost reduction

In the context of rising prices of raw materials, the importance of

reducing costs through assembly technology and new battery pack designs has

become increasingly prominent.

Tesla demonstrated the latest battery pack technology-structure battery.

The CTC method directly integrates the battery cell into the chassis of the

vehicle, removes the module and battery pack, greatly reduces the middleware in

the battery pack, and improves the volume utilization rate of the battery pack.

This also applies to its 2170 cells, which are expected to be compatible with

other size cells in the future.

Musk has said that after adopting CTC technology, it can save 370 parts,

reduce body weight by 10%, and reduce battery cost per kilowatt-hour by 7%.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

substitute for lead-acid batteries, and are the first choice for grid-connected

peak shaving, off-grid energy storage, photovoltaic energy storage, UPS, data

center and other industries.