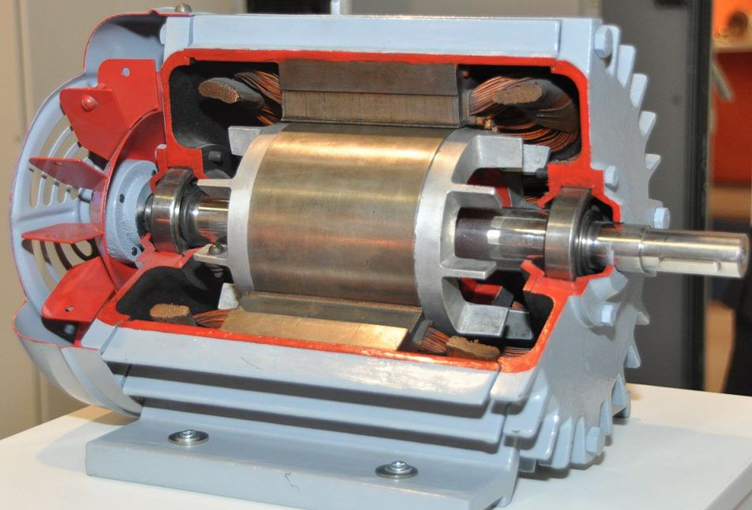

What impact does the plateau environment have on the performance of the

motor?

People have altitude sickness, so will motors also have altitude sickness?

In other words, what impact does the plateau environment have on the performance

of the motor?

The main features of the plateau environment are: 1. The air pressure or

air density is low; 2. The air temperature is low, and the temperature change is

large; 3. The absolute humidity of the air is small; 4. The solar radiation

illuminance is high; 5. The oxygen content of the air at altitude 5000m is only

53% of the oxygen content of sea level air; and so on.

These conditions are extremely severe tests for the ventilation and heat

dissipation conditions, insulation and protection of the motor. If the ordinary

motor is directly applied to the plateau environment, it may be burnt out due to

the deterioration of operating conditions or cause frequent failures.

In the product manual of the motor product, the normal working temperature,

humidity and altitude of the motor will be specified. Generally, the normal

operating temperature of the motor is -15 to 40 degrees, and the operating

altitude is below 1000 meters; while the altitude of the plateau motor is higher

than 1000 meters, and there are no more than 2000 meters, 3000 meters, 4000

meters, 5000 meters and other different levels.

At altitude, the following aspects should be paid attention to when using

the motor:

(1) The cooling effect of the air medium decreases, the heat dissipation

capacity decreases, and the temperature rise increases. For every 1000M

increase, the temperature rise will increase by 3-10%, so the temperature rise

limit must be revised.

(2) The higher the altitude, the greater the temperature rise of the motor,

the smaller the output power. However, when the temperature decreases with the

increase in altitude enough to compensate for the influence of altitude on the

temperature rise, the rated output power of the motor can be unchanged.

(3) The corona initial voltage is reduced, and the high-voltage motor

should be used to prevent corona when the high-voltage motor is used.

(4) The altitude is unfavorable to the commutation of the DC motor, so pay

attention to the selection of carbon brush materials.

(5) Cause the insulation strength to decrease: for every 1000 meters, the

insulation strength will decrease by 8-15%.

(6) The breakdown voltage of the electric gap decreases, so the electric

gap should be increased correspondingly according to the altitude.

The motor industry has plateau motors specially developed for the plateau

environment. It is divided into general-purpose plateau motors and plateau

outdoor motors.

General purpose heating plateau motors only need to consider the problem of

ventilation and heat dissipation, design according to the temperature rise limit

conditions of altitude conditions, and improve the ventilation and heat

dissipation conditions can be used in the plateau environment. In addition to

corresponding adjustments in insulation strength, electrical clearance,

temperature rise limits, and anti-corona measures, outdoor motors on plateaus

often need to adopt special ventilation and heat dissipation methods and

protective structures such as extreme temperature differences and wind and sand.

If necessary, to design the plateau outdoor special series motors according to

the specific environmental conditions.

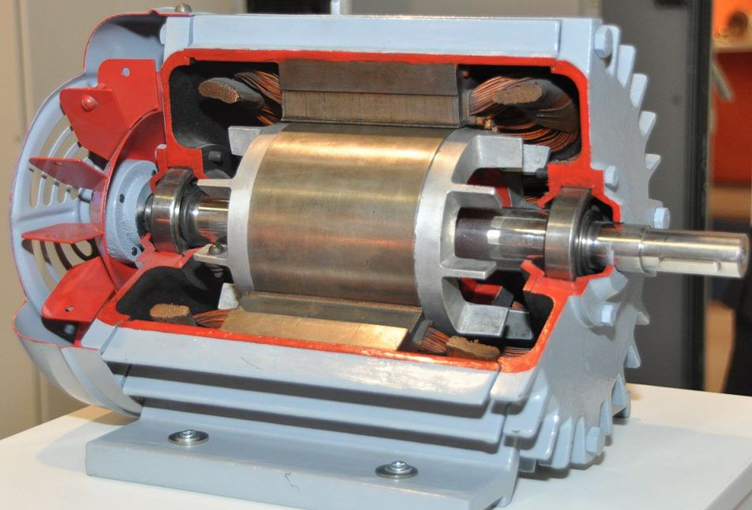

Special consideration should be given to the following factors in the

design of plateau motors:

1. The higher the altitude, the higher the actual temperature rise of the

motor, which means the smaller the output power. However, when the temperature

decreases with the increase in altitude enough to compensate for the influence

of altitude on the temperature rise, the rated output power of the motor can be

unchanged.

2. Stricter anti-corona measures should be taken when high-voltage motors

are used on plateaus.

3. The altitude is unfavorable to the commutation of the DC motor and the

insulation between the collector rings of the winding motor. Pay attention to

the selection of carbon brush materials.

4. Low air pressure in plateau areas and high volatility of lubricating oil

(grease) lead to increased mechanical wear.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

replacement for lead-acid batteries, and they are the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.

The motor system is matched with a high-rate performance lithium battery

system, which is a very promising way to use it.