Motors can be simply divided into DC motors and AC motors, and AC is

further divided into synchronous motors and asynchronous motors.

1. DC motor

The advantage of a DC motor is that it can easily adjust the speed by

changing the voltage and can provide a larger torque. It is suitable for loads

that require frequent adjustment of the speed, such as the mine hoists.

Now AC motors can also adjust the speed by changing the frequency, but the

price is more expensive than ordinary motors.

The disadvantages of DC motors are their complex structure and high failure

rate. Compared with AC motors, DC motors have complicated windings (excitation

windings, commutating pole windings, compensation windings, armature windings),

but also add slip rings, brushes and commutators. This not only places high

requirements on the manufacturer's process, but also the later maintenance costs

are relatively high.

Therefore, DC motors are in an embarrassing situation of declining in

industrial applications.

2. Asynchronous motor

The advantages of asynchronous motors are simple structure, stable

performance, convenient maintenance, low price and simple manufacturing process.

Therefore, it has been the most widely used in industry.

Asynchronous motors are divided into squirrel-cage motors and wire-wound

motors. The difference lies in the rotor. Squirrel-cage motors have high

reliability, but the disadvantages are that the torque is small, the starting

current is large, and the load that requires a large starting torque is

difficult to handle. The winding motor has higher torque and is suitable for

loads such as rolling mills and hoists. However, it adds slip rings, water

resistors and other accessories, and the price is relatively high.

If the asynchronous motor is to be used for high-power loads, it needs to

be equipped with a reactive power compensation device.

3. Synchronous motor

In addition to the advantages of synchronous motors that can compensate

reactive power in over-excitation state, they also have the advantages of

precise speed control, high stability, strong overload capacity, and high

operating efficiency.

Synchronous motors cannot be started directly, and asynchronous start or

frequency conversion start is required for cooperation. Therefore, one of the

disadvantages of synchronous motors is the need to add additional equipment for

starting.

Synchronous motors run by excitation current, so the second disadvantage of

synchronous motors is that they need to add excitation devices, which are mostly

supplied by silicon controlled rectifiers.

In summary, the principle of selecting a motor is that the motor

performance meets the requirements of the production machinery, and the motor

with simple structure, low price, reliable operation and convenient maintenance

is preferred. In this respect, AC motors are superior to DC motors, AC

asynchronous motors are superior to AC synchronous motors, and squirrel cage

asynchronous motors are superior to winding asynchronous motors.

For production machinery with stable load and no special requirements for

starting and braking, ordinary squirrel-cage asynchronous motors should be

preferred, which are widely used in machinery, water pumps, fans, etc.

Starting and braking are more frequent, and production machinery that

requires larger starting and braking torques, such as bridge cranes, mine

hoists, air compressors, and irreversible rolling mills, should use wound

asynchronous motors.

Where there is no requirement for speed regulation, a constant speed or

improvement of power factor is required, synchronous motors should be used, such

as medium and large-capacity water pumps, air compressors, hoists, mills,

etc.

The speed regulation range is required to be above 1:3, and the production

machinery that needs continuous, stable and smooth speed regulation should adopt

a separately excited DC motor or a squirrel cage asynchronous motor or

synchronous motor with frequency conversion speed regulation, such as large

precision machine tools, planers, rolling mills, hoists, etc.

The production machinery that requires large starting torque and soft

mechanical characteristics uses series-excited or compound-excited DC motors,

such as trams, electric locomotives, and heavy-duty cranes.

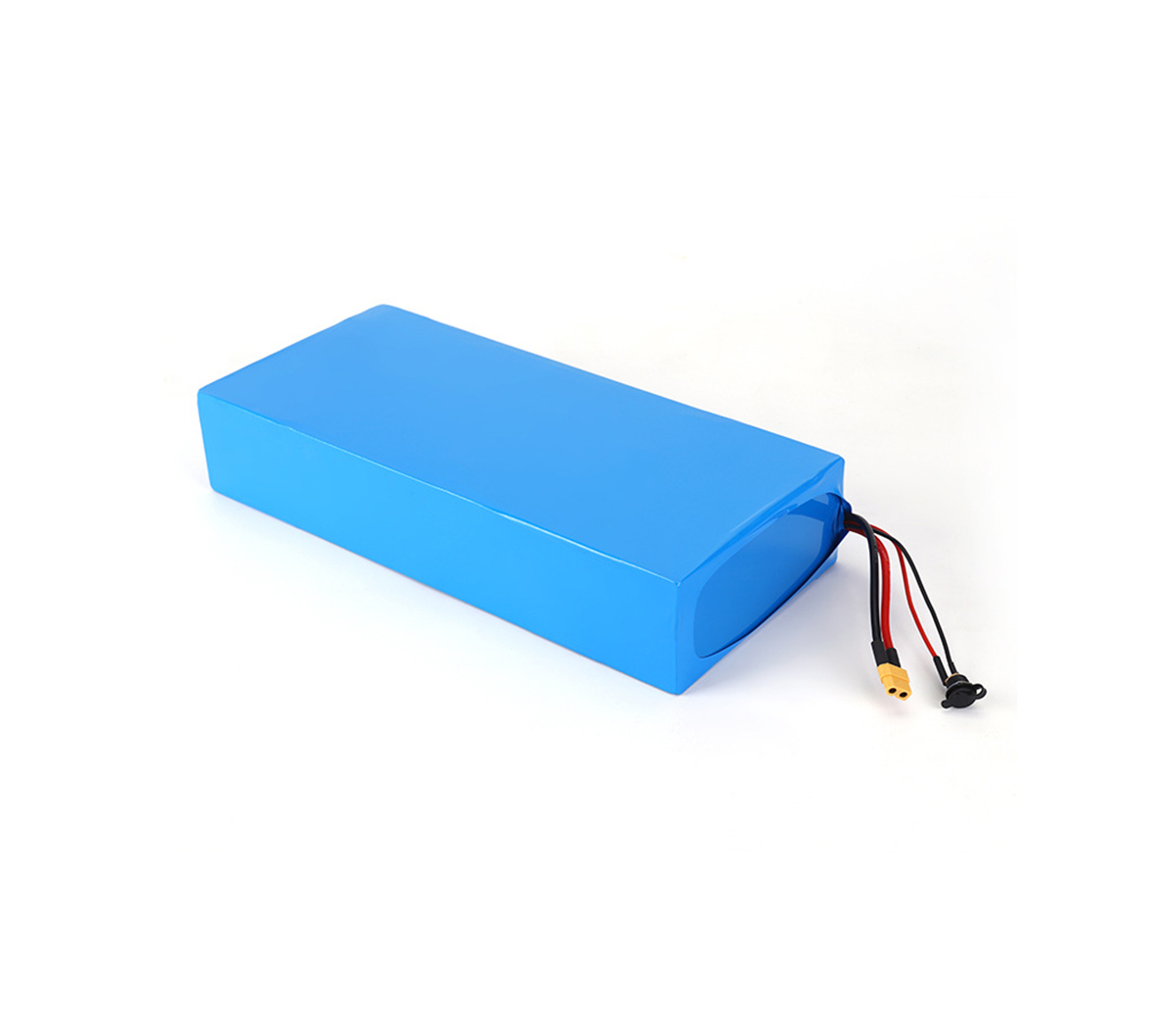

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

replacement for lead-acid batteries, and they are the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.

The motor system is matched with a high-rate performance lithium battery

system, which is a very promising way to use it.