In our perception, Tesla, as an electric car company with "extreme" technology development, can always make amazing moves in certain technologies, such as the induction ear 4680 battery it uses. Of course, in terms of battery technology, China, which is the world's most rapidly developing and leading electric vehicle, is naturally not far behind in this regard.

As a professional lithium battery energy storage system integrator with nearly two decades of experience, SES Power certainly has a strong interest in the products of Tesla, Panasonic, Samsung, LG, BYD, CATL, EVE and other famous companies in the industry, and we often study and refer to their design ideas, such as our products using lithium iron phosphate: UPS high-voltage lithium battery system (up to 860V ), 3Kw ~ 20Kw off-grid, grid-connected, islanding lithium battery energy storage system, wall-mounted form of home energy storage system 48V100Ah, 48V200Ah, stacked energy storage system (single 51.2V100Ah, up to support 15 stacks) and so on.

Let SES Power analyze BYD's latest patented battery technology: hexagonal lithium-ion battery!

A: What is a hexagonal lithium-ion battery?

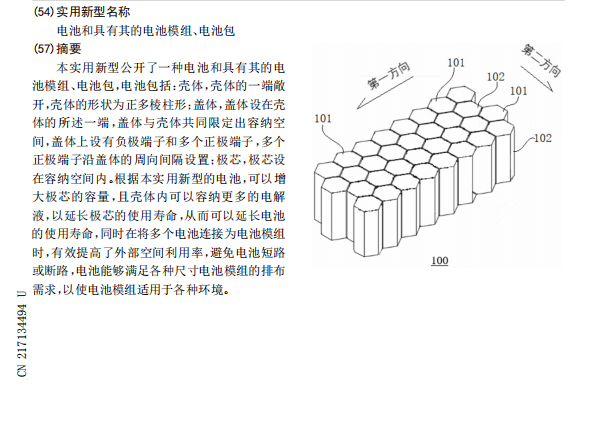

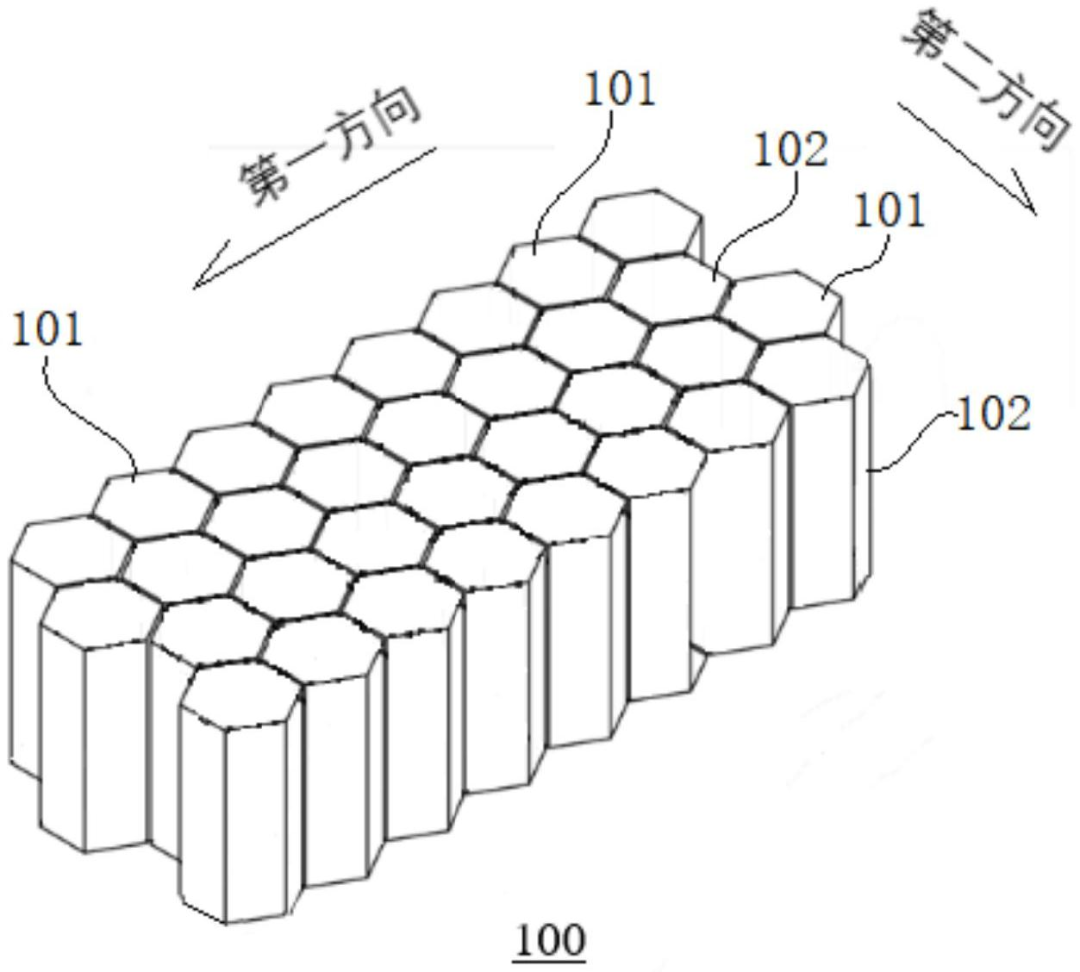

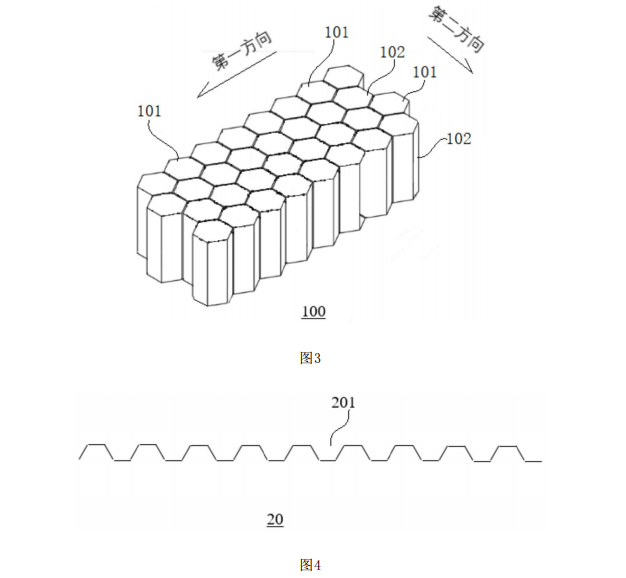

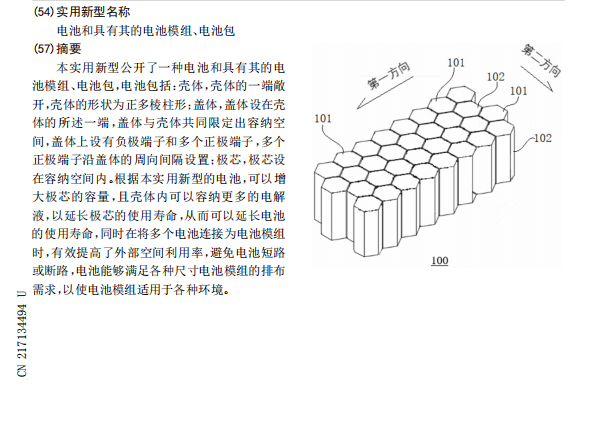

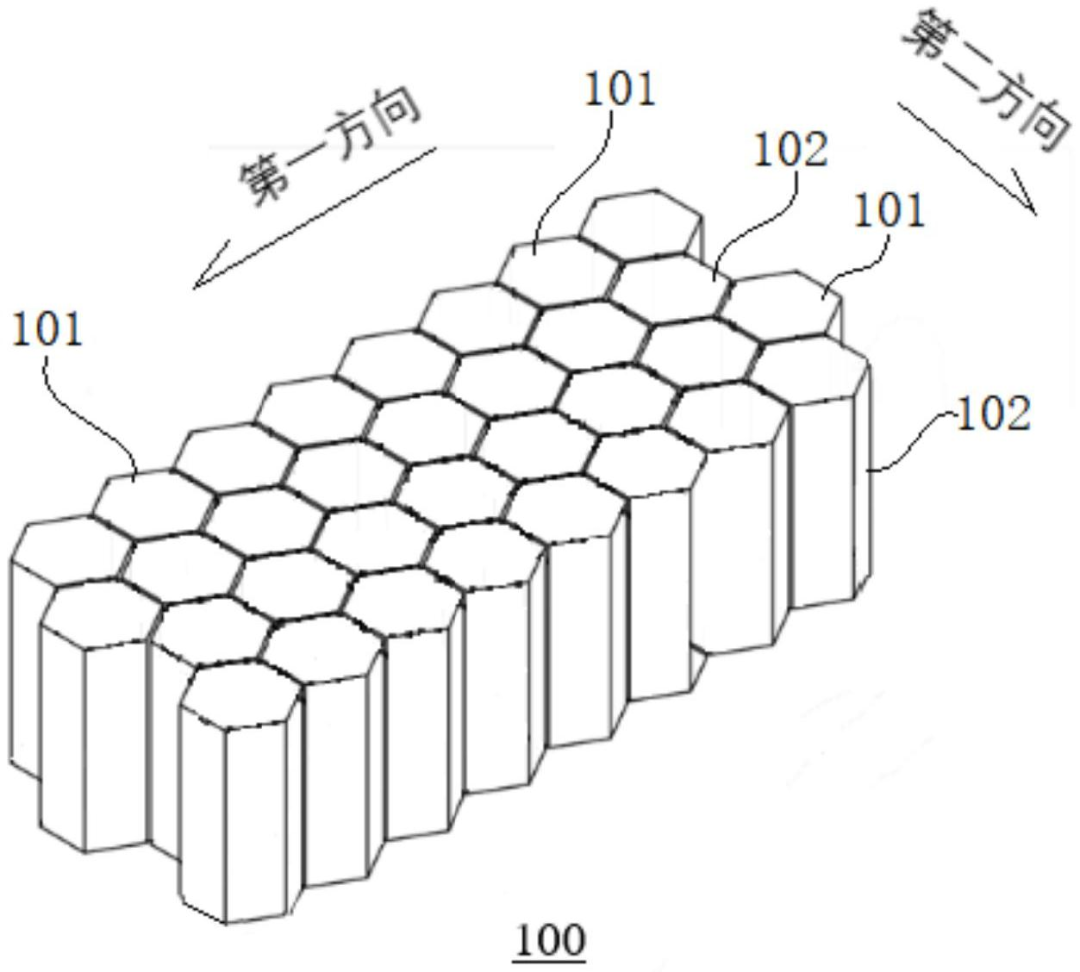

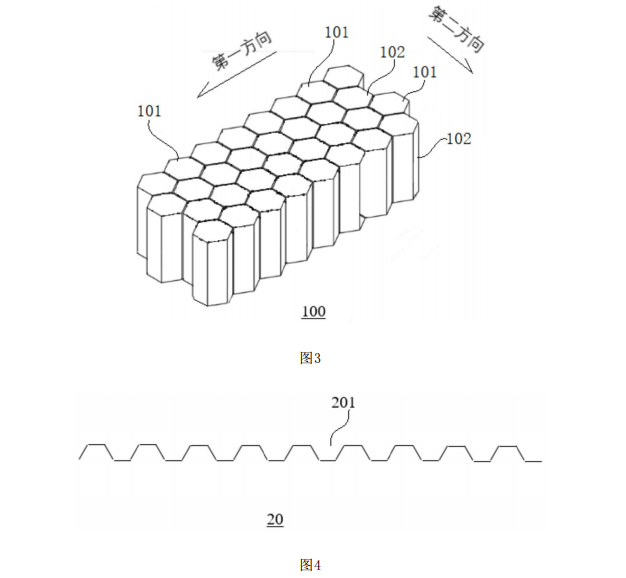

In a BYD patent note on power batteries, we see the latest prismatic battery patent from BYD. From the patent diagram, we can see that the entire battery arrangement is the same as the "honeycomb", which is made up of multiple hexagonal prisms.

The most important feature of BYD's new battery is that it is like a honeycomb, with a positive hexagonal prism structure. According to the data on the patent, the height of the entire shell (cover + shell) is between 60-150mm, and the diameter of the inner connection circle of the shell is between 15-60mm.

It is worth mentioning that the patent also mentions that "the height of the shell can be 90mm, and the diameter of the inner connection circle of the shell 1 can be 40mm", and according to the naming rules of the battery, we can call this battery "4090 battery". For reference, the height of the Tesla 4680 battery is 80mm and the diameter is 46mm.

B: Why is this battery designed as a hexagonal prism shape?

Is it just a "look" to distinguish it from the common cylindrical battery on the market?

Of course it is not that simple.

In the long history of human development, most of the scientific discoveries are originated from nature, and this hexagonal shape is also the same.

We have all seen bees, and the shape of the hive where they work and live is the hexagonal shape we commonly see.

Generally speaking, a hive is made up of numerous holes of the same size, each of which is hexagonal and surrounded by other holes, with only a wax wall separating the two holes.

Why is it hexagonal?

First, we know that equilateral triangles are the strongest structure of all, and arranging six strong equilateral triangles around each other yields an equilateral hexagon, the structure of the hive. The body of a bee is basically cylindrical, and the bee does not have extra space nor feel crowded in the house hole.

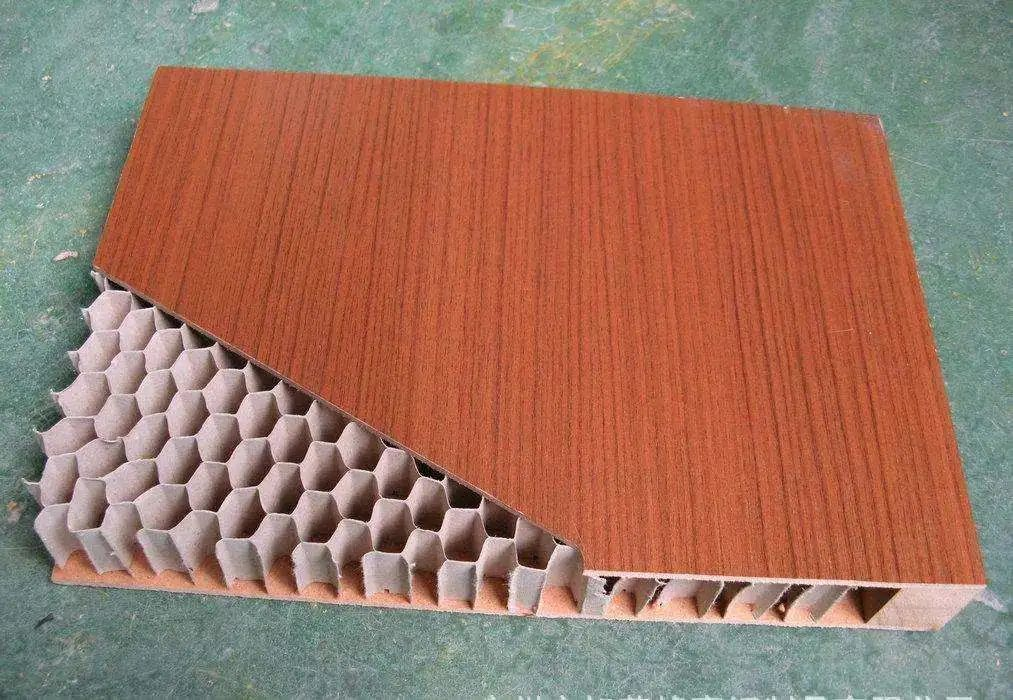

So scientists have concluded that the hexagonal honeycomb combination is not only sturdy, but also one of the most space-efficient ways to build.

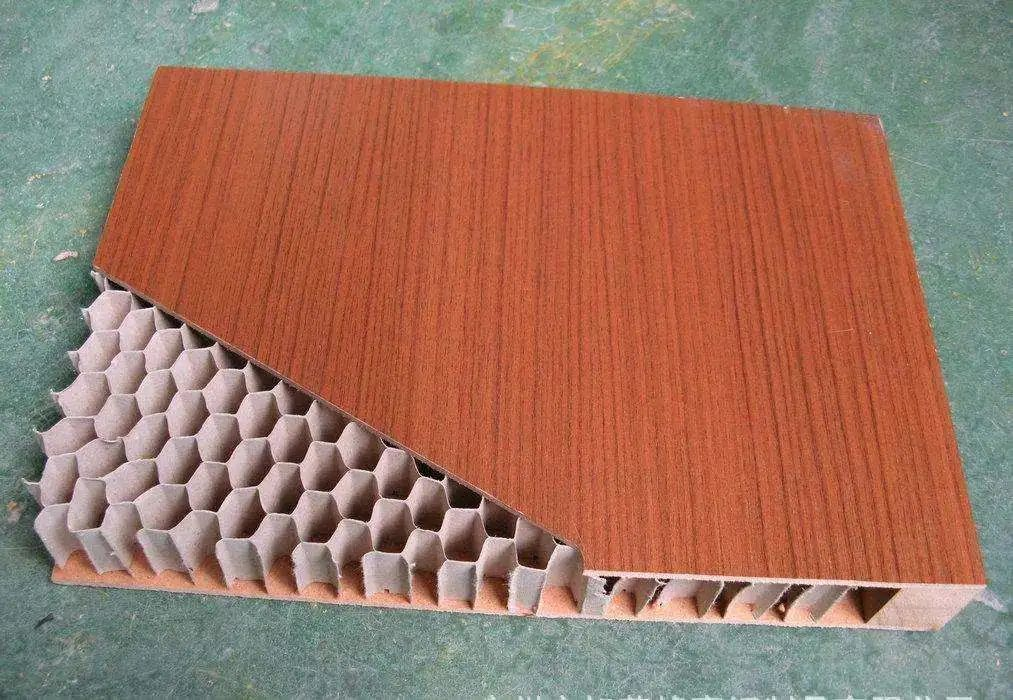

(The advantages of honeycomb construction are also used over cardboard for transportation or decoration)

C: The reality of the battery pack situation has given rise to new cell assembly technologies

For this issue, we must first start with the scenario of the application of these two batteries.

The current electric vehicle is full of desire and expectation in terms of range. In addition to the research and development pinned on the battery material, the factory needs to make corresponding technical developments in the optimized structural design of the battery pack.

The reason is simple, because in the whole battery pack also contains the battery management system, thermal management system, high and low voltage circuit and other components. Their distribution occupies part of the weight and internal space of the battery system, and their grouping efficiency is in the range of 60% to 70%!

This is a very helpless reality, according to the assertion made by a company, a single energy density exceeds 300Wh/kg cells, because the energy density at the level of the battery system is still about 160Wh/kg because of the limitation of the traditional battery pack grouping method.

Therefore, by optimizing the internal structure of the battery pack, throw away or simplify some construction to expand the space to accommodate more batteries, which can effectively improve the overall capacity of the battery pack, which is more representative of Tesla's CTC and BYD's CTB technology.

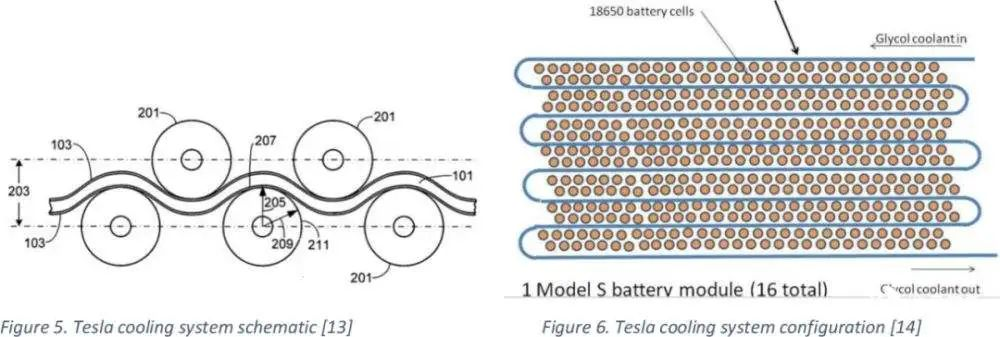

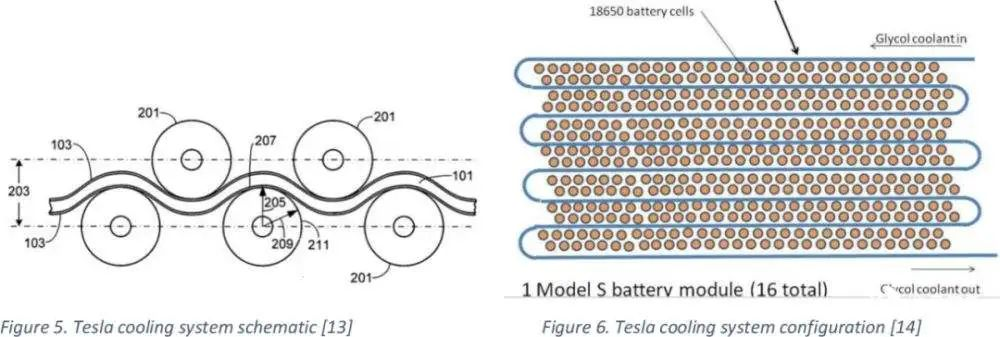

Tesla's CTC technology is known as Cell To Chassis. tesla will be staggered battery laid flat in the body chassis, in which the positive electrode is placed upward, in the positive end of the completion of the series-parallel connection of cells, and between the cells set up a serpentine tube to the side of the cells for cooling.

In simple terms, Tesla arranged the cells directly on the chassis, while the battery compartment was directly connected front and rear to two large body castings. There is no more cockpit floor, it is replaced by the battery top cover, and the seat is mounted directly on top of the battery top cover.

(Tesla's CTC)

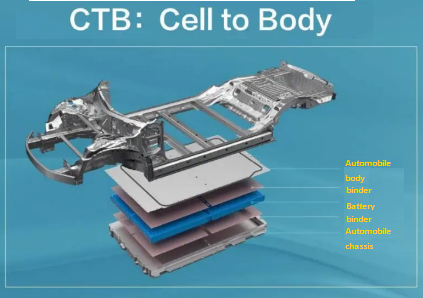

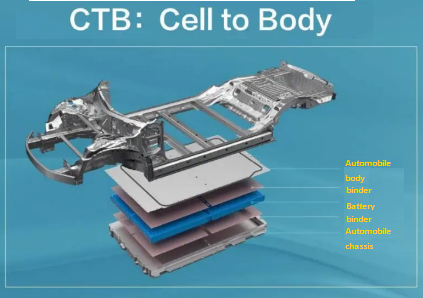

BYD's CTB technology, the full name is Cell To Body, which originally means the integration of battery and body. It integrates the entire battery cell into the body, with the upper battery cover replacing part of the interior floor and forming a flat, sealed, complete body with the front and rear beams to isolate the passenger compartment.

In this way, BYD integrates the battery system with the body as a whole, while the sealing and waterproof requirements of the battery itself can be met, and the sealing of the battery and the member compartment is relatively simple and the risk can be controlled.

Therefore, the characteristics of these two battery technologies have commonality, that is, the battery is completely flat in the chassis of the vehicle or against the chassis above the location, basically it carries more than the size of the vehicle battery capacity, more is becoming part of the body structure, so the strength requirements for the battery monomer is very high.

D: This six-pronged "4090 battery", compared to Tesla's 4680 battery, what advantages can bring?

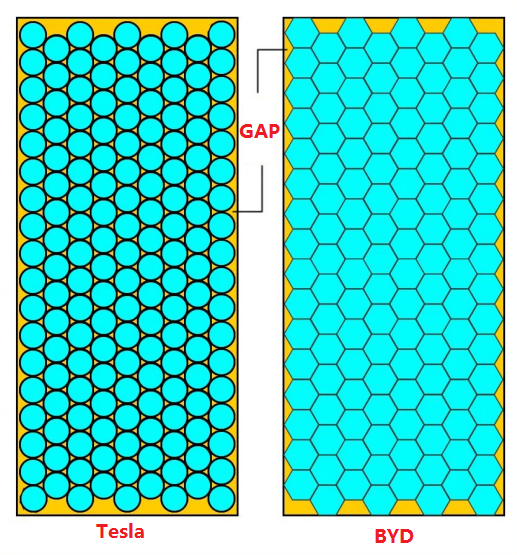

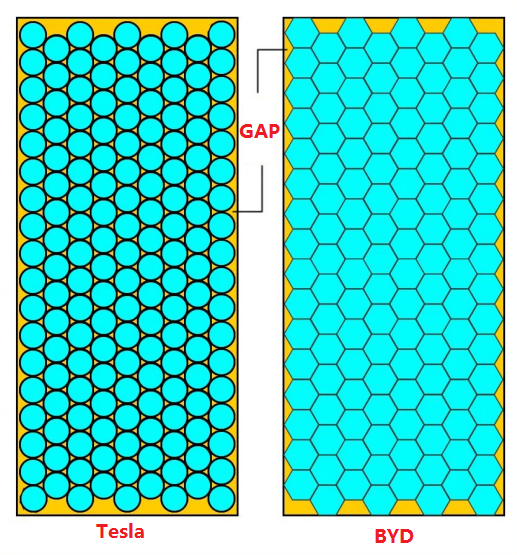

First of all, in terms of structural strength, when the 4680 cylindrical cells are combined together, the space between two adjacent cylindrical cells is large, which makes the mechanical stability of the cylindrical battery pack insufficient, and it is very easy to cause short circuit or breakage when subjected to external vibration or impact, which seriously affects the safety of the vehicle.

Hexagonal prismatic "4090 battery", after the group, due to its hexagonal structure, can make no gaps before the battery monomer, thus improving the structural strength of the battery pack.

In addition, there is news that the hexagonal prismatic "4090 battery" shell material may use aluminum alloy. This can ensure the strength of the power battery, but also reduce the weight of the battery pack.

The significance of this high-strength battery pack is not only in terms of safety, it may also be the future development trend of BYD.

Of course, some people suggest that square cells can be used, so that does not also remove the gap between the batteries?

In fact, the square-case single cell battery is in the combination of better stability and solid, but the square-case single cell battery is too large, low heat transfer efficiency, thermal management is difficult, long-term use of the cell expansion problem is difficult to solve.

In the choice for the battery type, the small size of the single cell battery will have more adaptability and versatility, while the square battery is too large as a single cell, so it is more conservative in adaptability and slightly less versatile.

In addition to the strength of the battery, 4680 cylindrical single cell and hexagonal prismatic "4090 battery" in other aspects also have different properties.

As we mentioned before when talking about the honeycomb structure, there is more space inside than in a circle because of the hexagonal structure. Therefore, the "4090 cell" with hexagonal prisms is happy to hold more electrolyte, which extends the life of the cells.

Another advantage of the honeycomb structure is that it improves external space utilization when connecting multiple cells into a battery pack.

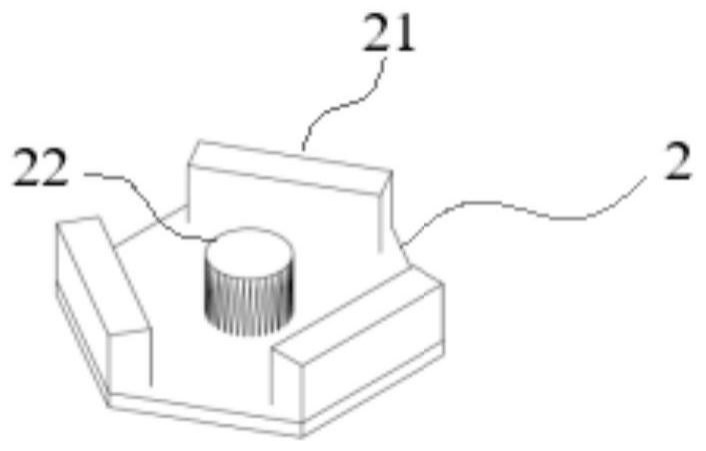

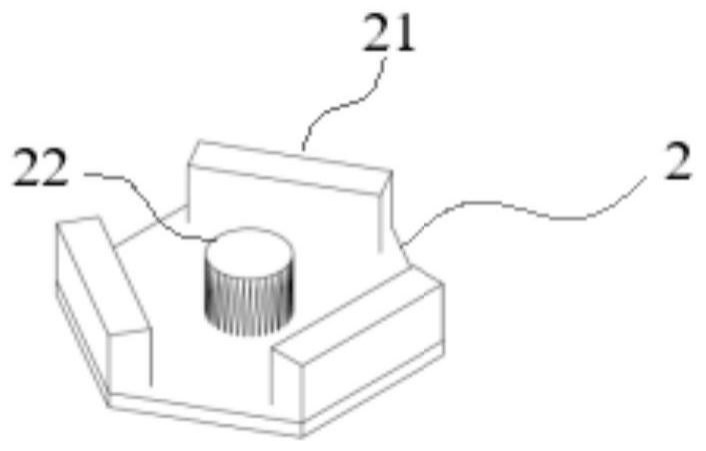

In addition, the two batteries also have very different structures in the positive and negative electrode pieces. From the patent diagram, BYD's hexagonal prismatic "4090 battery" cells have both positive and negative electrodes designed in this one cover: the cylindrical shape in the center is the negative electrode, and the three raised rectangles in the outer circle are the positive electrode.

Since the negative terminal is located in the center and the three surrounding positive terminals are spaced at equal distances, the resistance between each positive terminal and negative terminal is equal, thus ensuring the temperature uniformity of the battery and shortening the conduction path of electrons to a great extent.

This is equivalent to the fact that a traditional battery cell has only one pole ear, which is equivalent to a large office building with only one elevator. BYD's hexagonal prismatic "4090 battery" has a triple pole-ear structure, which is equivalent to having three elevators in an office building, so people can go up and down the stairs faster and the electron flow is smoother.

In addition, generally speaking, the battery cell will generate a lot of heat when working, and the heat of the battery cell is concentrated in the positive area, so BYD will be placed on the same side, which for heat dissipation, you can strengthen the single side more, which undoubtedly increases the flexibility of the layout.

In addition, BYD's hexagonal prismatic "4090 battery" is equipped with a heat sink between adjacent cells, the heat generated by two adjacent cells can be dissipated through the heat sink, which can increase the heat dissipation area of the battery and improve the heat transfer efficiency of the battery module, but it is not known what the specific layout of the heat sink structure is the style of but basically, they will use the more mature technology of liquid cooling to cool the battery.

Due to the use of a more compact honeycomb structure, so the BYD battery heat transfer will be very rapid. And Tesla's 4680 although there will be a lot of gaps in the battery arrangement, but the air between this gap will play a thermal resistance effect, so it will ease the occurrence of heat transfer.

BYD's main battery material now is lithium iron phosphate. And the type of battery in the charge and discharge of the heat generated by itself is lower than the ternary lithium battery, so it also more or less reduces the rate of heat transfer.

E: Tesla's 4680 battery, as it has its unique advantages?

Tesla's 4680 battery adopts the pole-less lug method, in fact, the pole-less lug is just an "exaggeration", it still has pole lugs. It still has lugs, but they are concentrated on one side, so it is more accurate to call it a full lug design.

The advantage of this design is that the positive and negative collectors are directly connected to the cover shell, thus exponentially increasing the current conduction area and shortening the current conduction distance. At the same time, it significantly reduces the internal resistance of the battery, reduces heat generation to prolong battery life, and increases the peak power of charging and discharging.

In addition, inside the battery pack, the serpentine tube is arranged parallel to the axle direction, which can reduce the length of the serpentine tube, thus reducing the flow resistance and increasing the uniformity of cooling. And on the side of the battery cell is equipped with eight pressure relief valves, almost all over the side of the battery pack, the advantage of this is that once the thermal runaway occurs, the pressure relief valve can be quickly opened to reduce the risk of battery fire.

Finally, say a few words about the manufacturing process of these two batteries.

F: There is no absolutely perfect battery, everything is progressing

On the whole, BYD's six-pronged battery is better than Tesla's 4680 battery in terms of structural strength, energy density and manufacturing process, but because of the more dense arrangement, BYD's six-pronged battery is still more doubtful in terms of heat dissipation. However, if the battery continues to use lithium iron phosphate material, I believe this problem will not have much impact on the battery.

Compared to Tesla has been assembled on the 4680 battery, BYD launched this six-pronged battery in the final product on the ground needs further development.

Although at this stage lithium iron phosphate is about 10-20% cheaper than ternary, but ternary power battery raw material prices will certainly return to normal levels, by then the cost advantage of lithium iron phosphate may disappear, plus lithium iron phosphate energy density is relatively low, does not meet the future trend of increasingly high power battery range requirements.

BYD only consider lithium iron phosphate system, they should take into account the future changes in the pattern of the battery market, increase the investment in research and development of high nickel or other types of high-density batteries, so this six-pronged column battery is more or less just a bridge to the future layout.

Batteries as both old and new trendy products, there will be no perfect technology produced at this stage, what SES Power and you can do is to follow the market demand closely and choose the right battery and technology to make the right battery products.

If you have any questions about batteries, you are welcome to contact SES Power.