An important parameter of lithium-ion batteries is the self-discharge

ratio, which is generally explained by the industry in accordance with the

monthly consumption capacity ratio under normal static conditions. This

parameter is a key parameter to examine the consistency of lithium-ion

batteries, and it is also a parameter that needs to be considered in the

assembly and replacement of lithium-ion batteries. The reason is very simple. In

the actual application process, the environment and use conditions are far more

difficult than laboratory conditions. Being complex and harsh, this magnifies

the effect of self-discharge parameters.

As a supplier of customized lithium-ion batteries for 20 years, SES Power

has developed and produced many lithium-ion batteries for different

applications, such as the lead-acid replacement product 12V100Ah made of square

aluminum-shell lithium iron phosphate batteries. , 24V100Ah, 12V200Ah, 3kwh,

5kwh, 10kwh wall-mounted smart home energy storage system, rack-mounted energy

storage system, split combined high-voltage power lithium battery system, polar

lithium battery that can withstand -60 degrees Celsius, starting current up to

2000CCA starter batteries, customized metal shell lithium iron phosphate

batteries, etc., these are very high capacity and high voltage lithium ion

battery pack products, so we have more strict research and requirements on

self-discharge parameters than others. The following is a brief introduction by

our senior engineers on how to measure the self-discharge of lithium-ion

batteries.

The measurement methods are mainly divided into two categories: 1) the

stationary measurement method, which obtains the self-discharge rate by standing

the battery for a long time; 2) the dynamic measurement method, which realizes

the parameter identification of the battery in the dynamic process.

The current mainstream lithium-ion battery self-discharge measurement

method is static measurement: under certain environmental conditions, the

battery is left to stand for a long time, and the change of battery parameters

before and after standing is measured to indicate the self-discharge degree of

the lithium-ion battery. . According to the different measurement parameters,

static measurement is mainly divided into three categories: capacity

measurement, open circuit voltage measurement and current measurement.

1. Volume measurement

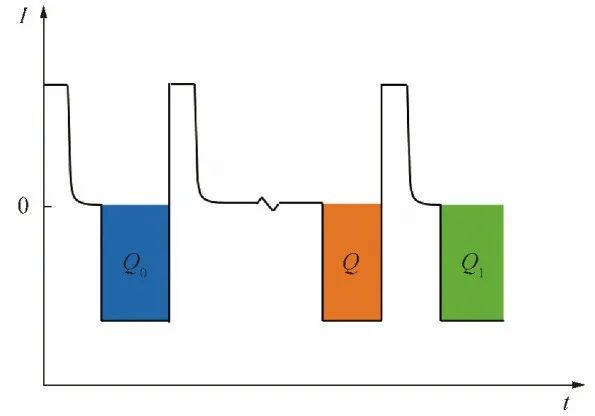

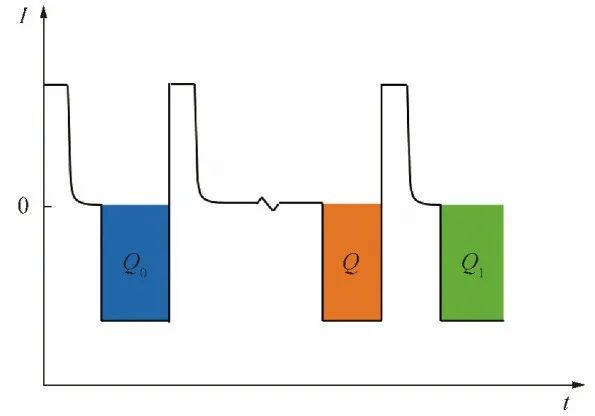

Before the battery is left standing for a long time, the battery is charged

and discharged once, and the discharge capacity Q0 before standing is recorded.

After standing, the battery was discharged in the same way, and the discharge

capacity Q after standing was recorded.

According to formula (7), the self-discharge rate η of the battery can be

calculated. The battery is charged and discharged again in the same way, and the

discharge capacity Q1 of the battery after the cycle is recorded. According to

equations (8) and (9), the reversible self-discharge amount Qrev and the

irreversible self-discharge amount Qirr of the battery can be calculated

respectively. This method is shown in the figure below.

The International Electrotechnical Commission (IEC) "Accumulators and

accumulators containing alkaline or other non-acid electrolytes: Portable

secondary lithium batteries and accumulators" (IEC 61960) stipulates that

batteries in a 50% SOC state will be Stored at ambient temperature (20±5)℃ for

90d, the discharge capacity of the battery after recharging should not be less

than 85% of the rated capacity. The electric vehicle battery test manual issued

by the US Automotive Research Council (USCAR) stipulates that the actual power

corresponding to the battery working range should be measured before the

measurement: after the battery is discharged at a C/3 rate of 50% of the

available power, the ambient temperature is 30%. Store at ℃ for 30 d, and

measure the discharge capacity of the battery after recharging.

The Performance Requirements and Test Methods for Power Batteries for

Electric Vehicles (GB/T 31486) issued by the Standardization Administration of

China (GB/T 31486) is similar to the IEC standard, and specifies the test

procedures for the measurement of charge retention and capacity recovery

capabilities. Taking the room temperature test as an example, the battery is

stored at room temperature for 8 days, and the charge retention rate is required

to be no less than 85% of the initial capacity, and the capacity recovery is no

less than 90% of the initial capacity.

2. Open circuit voltage measurement

Open circuit voltage measurement is to express the degree of self-discharge

of lithium-ion batteries by directly measuring the change of open circuit

voltage during battery standing. The advantage of this method is that it is

simpler and less time-consuming than measuring capacity; the disadvantage is

that for lithium-ion batteries (such as LFP batteries) with a long voltage

plateau on the open circuit voltage-SOC curve, in a large SOC range, The battery

voltage change is small, and it is difficult to characterize the degree of

self-discharge by measuring the open-circuit voltage, that is, the method has a

certain scope of application.

3. Current measurement

The lithium-ion battery is charged with a small current to keep the voltage

of the battery unchanged, and the charging current value when it is stable is

the self-discharge current. According to research, the tiny current may not

stabilize for several months, and the stabilization time of different designs of

batteries is not the same. Generally, the recommended measurement time is at

least one week.

This method has similar problems to the method of measuring open-circuit

voltage, namely, the validity of this method is challenged for lithium-ion

batteries (mainly lithium iron phosphate batteries) with a long voltage plateau.

In addition, since the self-discharge current of lithium-ion batteries is

extremely small, generally C/50000 or lower, to apply and measure this tiny

level of current requires higher requirements for experimental instruments.

Taken together, the above three methods are very time-consuming, and the

experimental time span ranges from one day to dozens of days. The shortening of

the measurement time in the current measurement scenario requires high equipment

costs.

In order to shorten the measurement time, save space resources and human

resources, researchers have introduced dynamic testing methods.

Change conditions such as ambient temperature and battery SOC

Such changes can greatly speed up the self-discharge rate, allowing

relatively large changes in the measured parameters in a relatively short period

of time. Although this method saves the experiment time, it also accelerates the

aging of the battery and increases the damage to the battery.

Modeling the equivalent circuit of a lithium battery

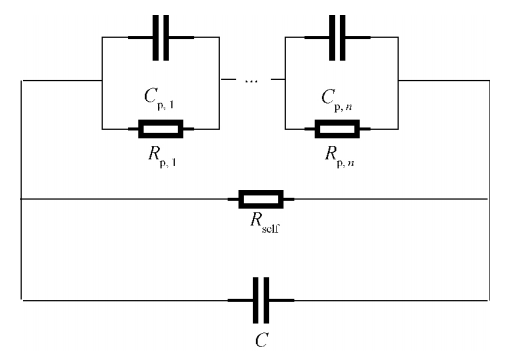

On the basis of the existing relatively mature equivalent circuit model of

lithium-ion battery, the self-discharge resistance is introduced, and the

self-discharge rate of lithium-ion battery is measured in the dynamic process

through different parameter identification methods.

We can simplify the lithium-ion battery into a first-order

resistor-capacitor (R-C) equivalent circuit, apply the same charge and discharge

current to the lithium-ion battery and the equivalent circuit, and adjust the

parameters of the equivalent circuit according to the difference in output

voltage until the two the difference approaches zero, and the self-discharge

resistance value of the lithium-ion battery is obtained.

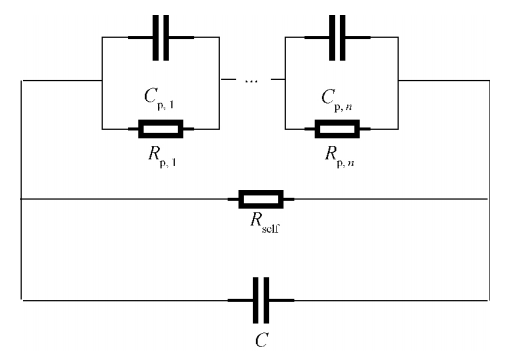

For example, we can simplify the battery to the equivalent circuit shown in

the figure below. Among them: Rp,i is the electrochemical reaction resistance,

Cp,i is the electric double layer capacitance, Rself is the self-discharge

resistance, and C is the battery equivalent capacitance. By applying a

short-time current pulse to the lithium-ion battery, measuring the voltage

change during the subsequent resting process, and further analyzing the

self-discharge resistance value. This method only considers the dominant

reaction in each stage during standing, which decouples the complex reaction

mechanism, reduces the amount of calculation and shortens the measurement

time.

Specifically, the overvoltage recovery plays a leading role in the initial

period of standing, and the self-discharge of the battery at the end of the

standing period plays a leading role. The time constant of self-discharge can be

analyzed by the data at the end of the static period, and then the voltage drop

caused by the self-discharge in the overvoltage recovery period can be

compensated, and the equivalent capacitance of the battery can be solved, and

finally the self-discharge resistance value can be obtained.

This method can obtain the self-discharge resistance of lithium-ion

batteries within 10-48 hours, which saves a lot of time compared with the

traditional method, but still needs to consume a lot of standing time in order

to observe the stage where self-discharge plays a leading role.

Statistical methods for outlier identification of parametric and depletion

effects

The parameter effect means that due to the existence of the short-circuit

resistance, the measured open-circuit voltage and internal resistance have a

certain deviation from the actual value; the consumption effect means that due

to the existence of the short-circuit resistance, the energy stored in the

battery is continuously consumed, and the battery SOC continues to decrease. It

will cause the actual value of the battery open circuit voltage and internal

resistance to have a certain deviation from the normal value.

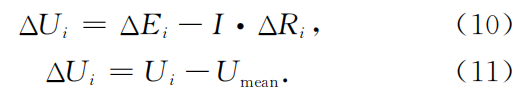

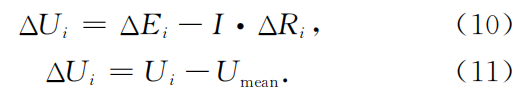

In the battery difference model shown in equations (10) and (11): Ei is the

open circuit voltage of the battery, Ri is the internal resistance of the

battery, and Ui and I are the measured battery voltage and current,

respectively. The values of ΔEi and ΔRi are obtained by the recursive least

square method, and finally the abnormal parameters exceeding the threshold are

identified by statistical methods, so as to judge whether the battery has an

internal short circuit. When the short-circuit resistance is 100Ω, the method

can realize the identification of the internal short circuit within 4h43min.

SES Power finally summarizes for you: By analyzing the measurement methods

of static measurement and dynamic measurement of the self-discharge rate of two

types of lithium-ion batteries, the main conclusions drawn include the following

three points:

1. Side reactions occurring at the interface of negative

electrode/electrolyte and positive electrode/electrolyte are the main sources of

self-discharge of lithium-ion batteries. Self-discharge can be suppressed by

modifying the surface of positive electrode and adding additives to negative

electrode and electrolyte. happened.

2. During the storage process of the battery, it should be avoided to be in

a too high or too low SOC state, and the ambient temperature and humidity should

be kept within a relatively low range.

The current mainstream self-discharge measurement method is static

measurement based on long-term static experiments. The biggest problem of this

type of method is that the measurement time is too long, resulting in a huge

waste of space and human resources. Researchers have proposed some dynamic

measurement methods combined with equivalent circuit models for parameter

identification, and these methods have made some progress in shortening the

measurement time. Through the innovative experimental design, the decoupling and

identification of self-discharge in the dynamic process is completed, which is

the key path and development direction to realize the rapid measurement of

self-discharge in the future.