People usually refer to battery energy storage devices as batteries, and

their working principle is to convert chemical energy and electrical energy into

each other through redox reactions. These reactions take place at two distinct

electrodes (positive and negative electrodes), which are connected by an

external circuit and physically separated by an ionically conductive medium

(i.e., the electrolyte).

The concept of "battery" first appeared in 1800, which proves that battery

energy storage technology has a long history of research, development,

demonstration and commercialization, resulting in many battery technologies and

product.

The battery technology used in battery energy storage systems in the power

grid is almost always secondary rechargeable batteries, which are characterized

by reversible redox processes.

What type of batteries do current energy storage systems use?

A: Lead-acid battery: It is a battery whose electrodes are mainly made of

lead and its oxides, and the electrolyte is sulfuric acid solution. Lead-acid

batteries are widely used in internal combustion vehicle engine starting,

on-board power, power system power or backup power, and it can also be used as a

backup power source for homes and businesses.

However, lead-acid batteries have many disadvantages: when they are

discharged deeply, rapidly, and with high power, the available capacity will be

greatly reduced; the energy density is low and bulky; the life is short and

needs to be replaced frequently; it contains harmful metals and is not

environmentally friendly.

B: Lithium-ion battery: It is a kind of secondary rechargeable battery that

uses lithium metal or lithium alloy as the negative electrode material and uses

non-aqueous electrolyte solution. The efficiency can reach more than 95%, the

discharge time can reach several hours, and the number of cycles can reach 5000.

times or more, the response is fast, and it is the practical battery with the

highest energy in the battery.

(How Lithium-Ion Batteries Work)

The mainstream power lithium batteries on the market are divided into three

categories: lithium cobalt oxide batteries, lithium manganate batteries and

lithium iron phosphate batteries. The lithium cobalt oxide battery has the

highest energy density, high price, poor safety, and a cycle life of about 1000

times; lithium iron phosphate battery has a relatively low energy density, low

price, high safety, and a cycle life of 2000 to 8000 times. These advantages

make lithium-ion batteries a mainstream technology for a wide range of

applications, ranging from portable electronics and power tools to electric

vehicles (EVs), stationary energy storage systems, mobile energy storage

systems, and home energy storage systems.

As of 2016, electronic equipment accounted for about 35% of the lithium-ion

battery market, electric vehicles and electric buses accounted for 50% (mainly

in China), and industrial and energy storage systems (such as grid storage,

uninterruptible power supplies) accounted for 5%; The remaining market for other

uses accounted for 10%, such as medical equipment, power tools and electric

bicycles. Since 2016, the growth of lithium batteries has been mainly driven by

the hybrid and electric vehicle market, electric buses, and industrial

applications. Since 1995, the market size of lithium-ion batteries has grown by

about 1000 times in terms of total energy storage capacity, and the global

production in 2019 reached about 100GWh.

SES Power focuses on Lithium Iron Phosphate (LFP) batteries, because we

have applied Lithium Iron Phosphate batteries in energy storage systems more

than ten years ago. Although the lower specific energy limits the application of

LFP batteries (such as electric vehicles that require longer driving range), LFP

has the advantages of stable power, high safety, particularly long life and low

cost, while LFP The output voltage can directly replace the lead-acid battery,

and even the discharge curve is close to the lead-acid battery, which especially

leads to its wide use in small and large industrial, commercial applications:

from power tools to residential and grid-scale energy storage applications

Lithium iron phosphate battery. LFP batteries are also increasingly being used

in batteries for passenger electric vehicles, where maximizing range is not a

priority. They may be the most attractive option for low-cost lithium-ion

battery cathodes in energy storage systems today.

The lithium iron phosphate batteries eliminated from pure electric vehicles

can still be used for a long time and can meet the needs of energy storage

systems. Therefore, many batteries eliminated from pure electric vehicles have

been transformed directly into energy storage systems, which can greatly reduce

the cost. the cost of the energy storage system

C: Lithium-sulfur battery, which uses sulfur as the positive electrode and

metal lithium as the negative electrode. Its theoretical specific energy density

can reach 2600wh/kg, and the actual energy density can reach 450wh/kg.

However, the battery is expensive and immature, and the charge-discharge

cycle life and safety are still difficult problems to solve (overcharging causes

heat, burning, and charging protection is required)

D: Sodium-sulfur battery: It is a secondary rechargeable battery with metal

sodium as the negative electrode, sulfur as the positive electrode, and ceramic

tube as the electrolyte diaphragm. Its cycle period can reach 4500 times, with

high energy density and fast response time.

At present, more than 200 such energy storage power stations have been

built in Japan, Germany, France, the United States and other places, which are

mainly used for load leveling, peak shifting and improving power quality.

Sodium-sulfur batteries have certain usage limitations, because they use

liquid sodium and operate at high temperatures, so they are easy to burn; when

the grid has no electricity to provide heating, it needs diesel generators to

help maintain high temperatures, or to help meet the conditions of battery

cooling.

E: Flow battery: a high-performance battery that separates the positive and

negative electrolytes and circulates them separately.

There are several systems for flow batteries, such as iron-chromium system,

zinc-bromine system, sodium-bromine polysulfide system and all-vanadium

system.

The disadvantages of flow batteries are: too large in size, too high

requirements for ambient temperature, expensive, very complex system, and more

or less environmental problems.

Lead-acid batteries have gradually withdrawn from grid-scale energy storage

systems due to life, volume, weight, environmental protection and other reasons.

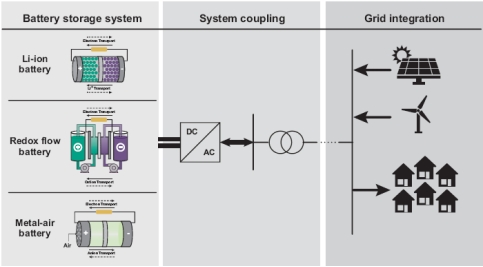

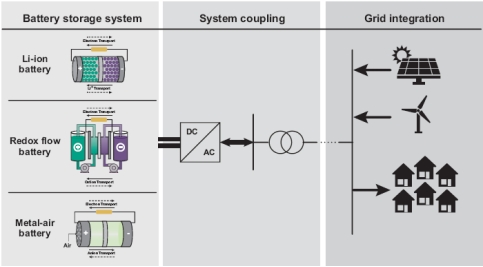

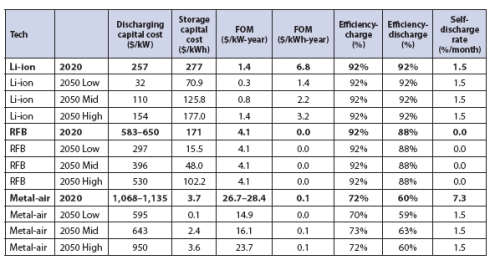

Electrochemical batteries that have proven to be more promising for future

deployment at this stage fall into three main categories: lithium-ion batteries,

flow batteries, and metal-air batteries, as shown in the figure below.

(Main categories of battery technology)

How to correctly view the battery cost in the battery energy storage

system?

Battery energy storage systems generally have a higher energy density than

mechanical or thermal energy storage systems and can achieve decent round-trip

efficiency (ratio of energy output to energy input), some lithium-ion batteries

have round-trip efficiency as high as 95%, while some the round-trip efficiency

of some metal-air batteries may be as low as 40%.

While high-energy-density batteries are favored in consumer electronics,

such as lithium cobalt oxide batteries, size is not the most important

consideration in battery energy storage systems, but rather cost and service

life. Generally speaking, the battery accounts for 65%~75% of the cost of the

battery energy storage system, other electronic and mechanical accessories such

as PCS account for about 20%, and the rest is about 10% of the infrastructure

cost.

In these cost components, the battery is the obvious first consideration

and the accessory with the most downside. So SES Power focuses on analyzing the

cost of batteries for you.

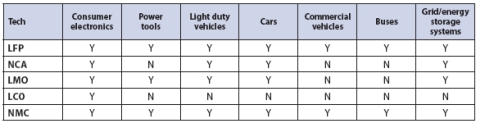

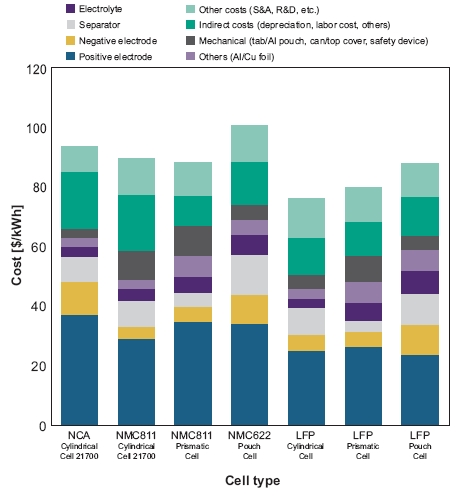

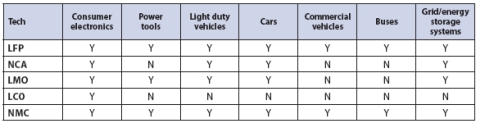

Various cathode compounds are used in lithium-ion batteries depending on

the desired combination of energy density, power density, lifetime, safety, and

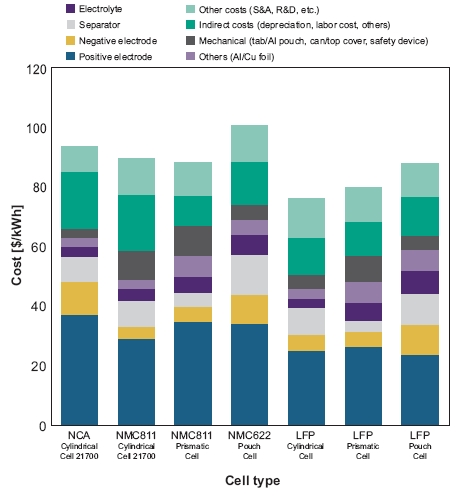

cost. The diagram below shows the most common series of battery cathodes today

and their corresponding applications. The cathode material is usually the most

expensive single component in a battery, accounting for 30% to 50% of the total

material cost.

(Lithium-ion battery cathode material classification)

(various lithium-ion battery cost breakdown)

Each battery contains trade-offs in energy density, safety, durability, and

cost, and the system architecture is often optimized for a specific application.

Historically, the development of rechargeable batteries has been driven by

applications in the transportation industry.

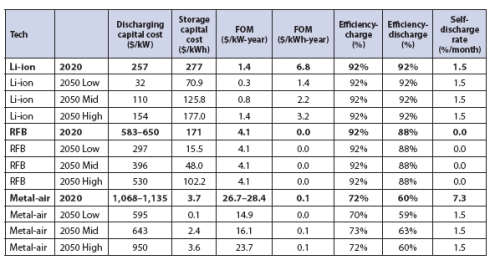

In emerging stationary energy storage applications, battery cost and

longevity are priorities, and in some cases, some batteries sacrifice energy

density or round-trip efficiency. Notably, Li-ion batteries are limited to

specific architectures that tend to incur lower power costs but higher energy

costs.

(Capital cost, operating cost, efficiency and self-discharge rate for

Li-ion, flow and metal-air batteries)

This makes Li-ion batteries most competitive for short-term energy storage

(less than 4 hours duration) applications because of relatively low capital

costs. With the rapid development of electric vehicles, the cost of lithium-ion

batteries is expected to drop rapidly, which may make lithium-ion batteries

competitive in 8-hour energy storage systems (long-term energy storage

systems).

The price of lithium-ion batteries has fallen by 97% since 1991). From 2010

to 2019, lithium-ion battery prices fell by about 85%. The total market size has

increased from about US$9 billion in 2008 to US$37 billion in 2019; by 2027, the

market size of lithium-ion batteries is expected to reach US$129 billion.

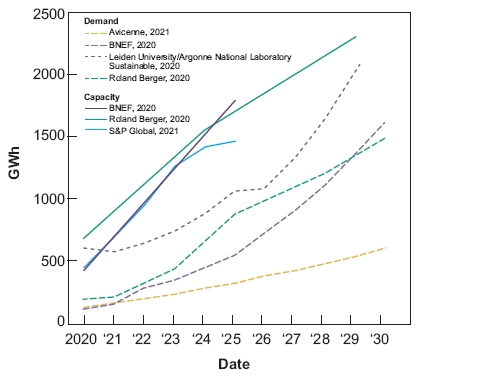

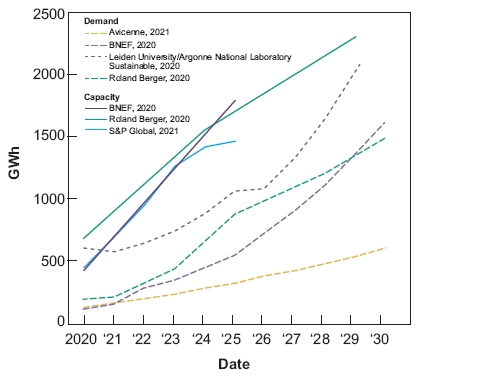

Multiple forecasts point to a huge increase in lithium-ion battery manufacturing

capacity between now and 2030, mainly driven by the growth of the electric

vehicle market. Global manufacturing capacity will grow rapidly from the current

500GWh and is expected to reach 2,500GWh by 2030.

(Projected growth in global lithium-ion battery manufacturing capacity and

demand from 2020 to 2030)

The U.S. Department of Energy’s (DOE) Office of Vehicle Technologies has

set a near-term (2028) target for lithium-ion battery costs at $60/kWh. The

industry expects the average price of lithium-ion battery packs to be below

$100/kWh and $58/kWh by 2024 and 2030, respectively. Tesla expects a series of

technological advancements to reduce battery pack costs from about $125/kWh in

2020 to $55/kWh in 2025.

In addition, several future directions are expected to further reduce costs

and make Li-ion technology more suitable for grid applications. One is to use

low-cost lithium-ion batteries, especially LFPs. Other possibilities include

developing lower-cost battery manufacturing methods, using materials more

efficiently, and simplifying manufacturing.

Flow batteries and metal-air batteries typically use a wider range of

chemistries, including highly abundant and low-cost active species (eg, iron,

zinc, oxygen), which makes the capital cost of these batteries attractive. In

addition, the architecture of flow batteries and metal-air batteries enables

integrators to perform regular maintenance on certain energy storage components,

thereby reducing energy storage costs over a long service life. However, these

battery technologies are relatively immature, limited engineering experience,

manufacturing costs, uncertainty of methods, and lack of a developed supply

chain will bring obstacles and troubles to energy storage system integrators,

because this is practical, Operations and Finance Cornerincreased risk.