Electrochemical energy storage is the type of energy storage with the

highest proportion of installed capacity, the most abundant application

scenarios and functions in new energy storage. The choice of battery technology

route has gone through a confusing process. Lithium batteries, sodium-sulfur

batteries, flow batteries and many other types are currently dominated by

lithium iron phosphate batteries. However, lithium iron phosphate batteries have

not become the "ultimate answer", new battery technology routes are still

emerging or evolving, and the exploration of battery technology routes is still

continuing.

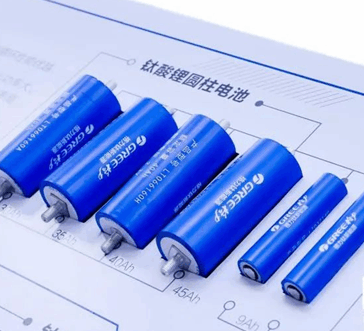

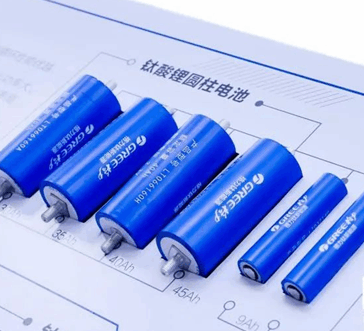

Before 2017, except for the commercial application of thermal power

frequency regulation projects in a few areas, the development of electrochemical

energy storage was generally in the stage of experimental demonstration, and the

industry was in the stage of exploring the characteristics of various energy

storage batteries. For example, for the wind and solar energy storage project

put into operation in 2011, battery technology routes such as lithium iron

phosphate battery, lithium titanate battery, all-vanadium flow battery, and

lead-carbon battery were used for demonstration and verification; Demonstration

and verification of lithium titanate battery and lithium iron phosphate battery.

Through these projects, the performance and operating characteristics of various

types of batteries are analyzed and summarized, which lays the foundation for

the commercial application of energy storage batteries.

At the same time, the electric vehicle industry is developing rapidly, and

lithium batteries, mainly lithium iron phosphate batteries and ternary lithium

batteries, have brought performance improvements and rapid cost reductions

through scale and industrialization, especially lithium iron phosphate

batteries. It has the advantages of high energy density, many times of charge

and discharge, high conversion efficiency, safety and so on. With the advantages

of industrialization, the cost of lithium iron phosphate batteries is declining

rapidly. According to relevant data, the cost per watt-hour of lithium iron

phosphate batteries has dropped from about US$0.5/Wh in 2010 to about US$0.12/Wh

by the end of 2020.

The exponential decline in price and the improvement in performance make

lithium iron phosphate batteries have the advantage of full life cycle cost,

thus gradually becoming the dominant choice in the market. According to

statistics, in 2021, among the new electrochemical energy storage technologies

in China, the installed capacity of lithium-ion battery energy storage

technology will reach 1830.9MW, and the power scale will account for as high as

99.3%; the installed capacity of lead battery energy storage technology will be

2.2MW; The installed capacity of battery energy storage technology is 10.0MW;

the installed capacity of other electrochemical energy storage technologies is

1.52MW.

At the same time, although lithium iron phosphate batteries are relatively

safe, they are not absolutely safe. There have been many accidents in recent

years, and the pursuit of safer batteries has always been the goal of the

industry. In addition, since 2021, the skyrocketing prices of raw materials

including lithium carbonate have led to a rapid increase in the construction

cost of energy storage power stations. Since the second half of last year, many

energy storage projects have entered a wait-and-see stage, which has also

prompted the industry to turn its attention to other battery types, such as

liquid flow Batteries, lithium titanate batteries, sodium ion batteries, etc.,

although other battery types still have a certain gap from lithium iron

phosphate batteries in terms of technological maturity and cost, but with the

development of technology and the improvement of the industrial chain, they will

gradually change from The experimental demonstration is moving towards

commercial application.

Today's energy storage system integrators are turning to offering

standardized, modular and integrated products that are simpler to assemble and

install in the factory. There is no doubt that this route has indeed become the

consensus of many lithium battery energy storage system integrators, and SES

Power is also advancing on this route, 36V100Ah, 48V100Ah, household energy

storage 3KW, 5KW systems, rack-mounted energy storage systems and other

products. Almost all of these products are standardized and modularized,

integrating RS485, CAN and other communication protocols to support remote

monitoring and operation. At the same time, AI intelligent analysis and cloud

storage are added to the new generation of systems to ensure system

compatibility, high speed and reliability.

At present, new technology routes for energy storage batteries are

emerging, including aluminum-ion batteries, solid-state lithium-ion batteries,

metal-air batteries, and lithium slurry batteries. The diversification of

technical routes can meet the needs of different application scenarios and

functions. In the application of projects, there are often differences in

short-term or long-term energy storage, shortage of land resources or abundant

areas, and large differences in natural environment. Diversified routes can

adapt to different needs. For example, as new energy gradually becomes the main

energy source, long-term Time energy storage will become its indispensable

element, while lithium iron phosphate is not suitable for long-term energy

storage needs, and more suitable energy storage types need to be developed.

SES Power believes that with the continuous improvement of energy storage

battery technology, the maturity of the market model, and the rapid expansion of

application scale, the era of energy revolution supported by energy storage

technology has quietly arrived. To develop high-safety, low-cost,

high-reliability, long-life, and environmentally friendly energy storage

batteries to reduce the cost of the entire life cycle of the system, the

industry still needs to continue to make efforts.