Lithium-ion secondary batteries (LIBs) are the mainstream energy storage

devices in the field of new energy today. Lithium iron phosphate (LiFePO4) has

become one of the most widely used cathode materials for lithium-ion batteries

due to its high energy density, low cost, stable charging and discharging

platform, environmental friendliness, and high safety.

As a manufacturer with nearly 20 years of experience in lithium battery

customization services, SES Power has been paying attention to the development

of the lithium battery industry, especially the development of lithium battery

cathode materials. Because the cathode material is the core of almost all raw

materials of lithium batteries. When SES Power first made a lithium battery pack

in 2008, it used the 18650 model of lithium iron phosphate battery with a

capacity of only 1200mah. By 2021, the capacity of this model can reach 2000mah,

which is almost doubled. times. Our energy storage products, such as 12V100Ah,

12V200Ah, 24V100Ah, 24V200Ah, 36V100Ah, 48V50Ah, 48V100Ah, and the home energy

storage system HESS (3KW inverter output) using square aluminum lithium

batteries, were unimaginable ten years ago. A single cell reaches 100Ah or even

280Ah. Similarly, SES Power's custom lithium-ion batteries can now be used in

-60 degrees and -40 degrees Celsius. These products were almost unimaginable

before.

With the development of the new energy industry, customers have put forward

higher requirements for the electrochemical performance of batteries such as

cycle stability, high-rate performance, and energy density. How to improve its

output power, energy density and service life at low temperature is the main

challenge for lithium iron phosphate cathode materials. According to the

research of SES Power, element doping improves the electrochemical performance

of the material, the protection mechanism of different capping agents for

lithium iron phosphate, and the high-capacity lithium-replenishing material.

These three methods can effectively improve the electronic conductivity and

ionic conductivity of lithium iron phosphate cathode materials. Diffusion rate

to achieve higher energy density, longer cycle life and higher rate capability

of the material.

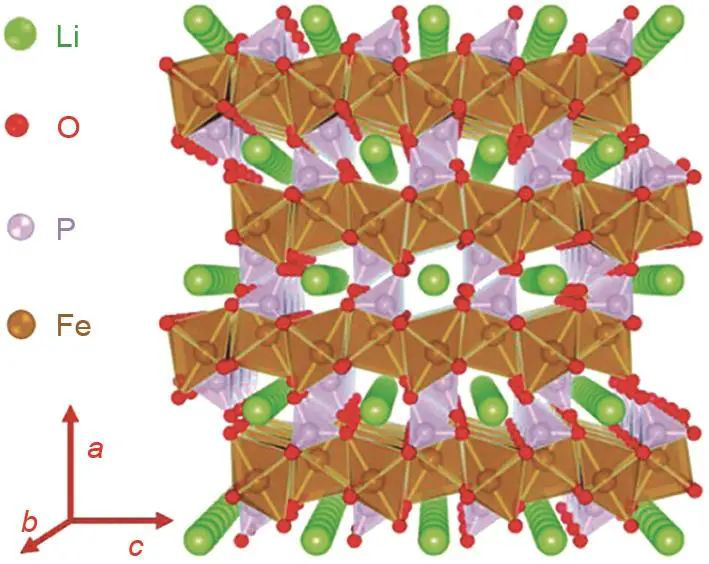

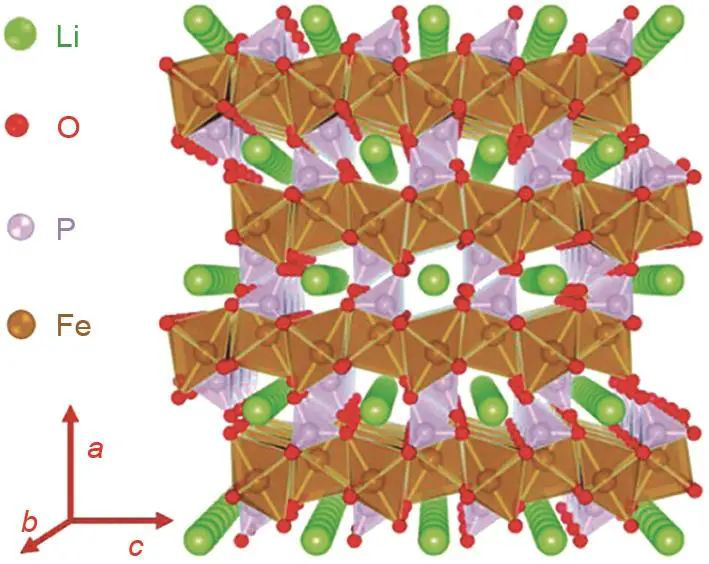

(Crystal structure of LiFePO4 viewed from the Li+ one-dimensional diffusion

channel)

A: Challenges faced by LiFePO4

LiFePO4 material has stable charging and discharging platform, high

specific capacity, good safety, less self-discharge, low cost and no pollution

to the environment. However, LiFePO4 is limited by its own crystal structure,

poor conductivity and slow ion migration rate, which greatly limit the

improvement of its electrochemical performance. In a sub-zero temperature

environment, the energy density of LiFePO4 batteries decreases, shortening the

battery life and increasing the operating cost of the battery system.

B: LiFePO4 improvement method

Due to the low ion diffusion rate and poor electrical conductivity of

LiFePO4, it has a great impact on the rate capability and low temperature

performance of LiFePO4. Therefore, how to improve the ion diffusion rate and

electrical conductivity of materials, so as to further effectively improve the

rate performance and low temperature performance, has always been the focus of

researchers.

b.1 Element doping modification

Element doping is considered to be an important method to improve the

internal electronic conductivity and ionic diffusivity of LiFePO4 materials.

This method can improve the charge-discharge performance of LiFePO4 material at

high current density.

The electrochemical data suggest that a moderate amount of Na doping can

improve the electrochemical performance. Li0.99Na0.01FePO4 exhibits excellent

rate performance and cycling stability, with an initial discharge specific

capacity of 80.9 mA h/g at a current density of 10 C and a capacity retention

rate of 86.7% after 500 cycles.

A small amount of Mn doping can improve the electrochemical performance of

the material, but too much doping will cause Li/Fe inversion defects and even

destroy the material structure. Although LiFePO4 doped with Mn element has

better electrical conductivity, its structural stability is relatively poor.

With the increase of Mn doping amount, in addition to the decrease in rate

performance, the dissolution of Mn2+ will change the structure of the cathode

material and reduce the discharge capacity.

Two-element doping is a good method, and Li site doping and Fe site doping

are usually the most studied.

Multi-ion co-doping mainly incorporates two or more metal elements into the

LiFePO4 structure, and integrates the advantages of each doped metal ion to

improve the electrochemical performance.

All in all, element doping can improve the internal conductivity of LiFePO4

material particles and accelerate the diffusion of lithium ions, and is still

the mainstream choice for optimizing material properties.

b.2 Material cladding

To prepare LiFePO4 with excellent electrochemical performance, only doping

is not enough. The conductivity of LiFePO4 is extremely poor. By coating the

surface of the material with a suitable conductive/ion-conducting material, the

electronic and ionic conduction between the particles of LiFePO4 can be

improved.

The types of coating agents mainly include carbon materials, metal or metal

oxide materials, and ion conductive materials. Among them, coating LiFePO4

material with conductive material is an important measure to improve its rate

and low temperature performance, and carbon material is the simplest and

cheapest kind of excellent material.

Graphene has the advantages of high electrical conductivity and porous

structure, and it is also a good direction. The improved LiFePO4 with graphene

has excellent cycling and rate performance. The discharge specific capacity was

160 mA h/g at 0.2 C rate, 107 mA h/g at 60 C high rate, and the capacity

retention rate over 2000 cycles was 95%.

Metal or metal oxide and carbon composite metal material coating is also

feasible, the battery conductivity is significantly improved, and the tap

density is also improved. However, the metal coating has an oxidation problem,

and the metals introduced are generally precious metals, which are not suitable

for mass production.

Ion conducting materials can also be used to improve LiFePO4 cathode

materials.

b.3 Adding Lithium Supplementary Materials

During the first charging process of LiFePO4 batteries, due to the

formation of a solid electrolyte interface (SEI) on the surface of the negative

electrode, about 5% to 20% of the lithium in the positive electrode material is

consumed, resulting in excessive irreversible capacity loss. We can add lithium

supplementary material to the lithium iron phosphate positive electrode

material. During the charging process of the battery, the lithium supplementary

material decomposes and releases excess lithium to compensate for the

irreversible lithium loss caused by the formation of the SEI film on the

negative electrode. Lithium supplementation materials usually have the

characteristics of strong lithium supplementation ability, easy synthesis,

strong stability and low cost. Common lithium iron phosphate cathode

supplementary materials include Li2O, LiF, Li3N and Li2S.

C: Summary and Outlook

After nearly 30 years of development, LiFePO4, as a commercialized cathode

material, still has many aspects worthy of further research. In the future, the

research on LiFePO4 cathode materials can focus on the following aspects.

(1) Industrialized production improvement. The cathode material of LiFePO4

has been industrially produced, but there are disadvantages such as high energy

consumption and poor rate performance of the produced material, and there is

still a lot of room for improvement.

(2) The combination of various improvement strategies can further improve

the rate performance of LiFePO4, and realize the ultra-fast charging

characteristics and excellent low-temperature long-cycle performance of the

material.

(3) Further in-depth theoretical research, to study the thermodynamic and

kinetic transformation process of LiFePO4 material in the process of charging

and discharging.

(4) Develop solid-state electrodes. Combining the LiFePO4 cathode material

with a solid electrolyte produces a new type of lithium battery that is safer

and can be used in flexible wearable electronic devices.

SES Power believes that LiFePO4, a cathode material for lithium ion

batteries, has broad application and development prospects in the commercial

field. It is believed that through the joint efforts of researchers, the further

performance improvement of LiFePO4 cathode material can maximize people's

production and life needs.