What is the core technology of the battery management system (BMS)?

BMS is the core component of lithium batteries, especially energy storage

systems, electric vehicles and other products that need to be applied to

large-scale battery combinations. Its importance is beyond doubt.

Many BMS manufacturers on the market claim to have their own so-called core

technologies, and some new terms are constantly emerging, causing headaches for

R&D engineers. So, what is the core technology of the real BMS?

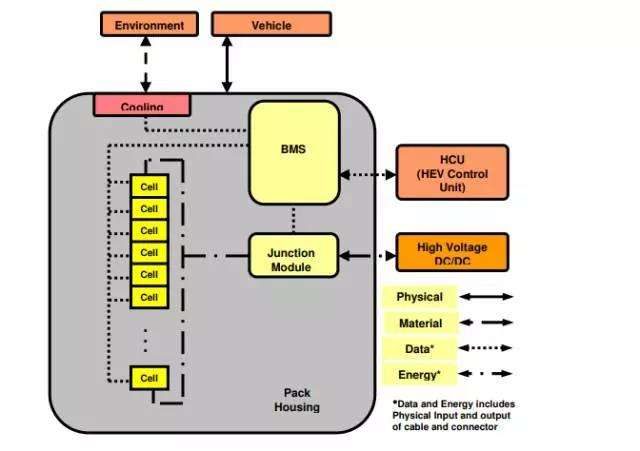

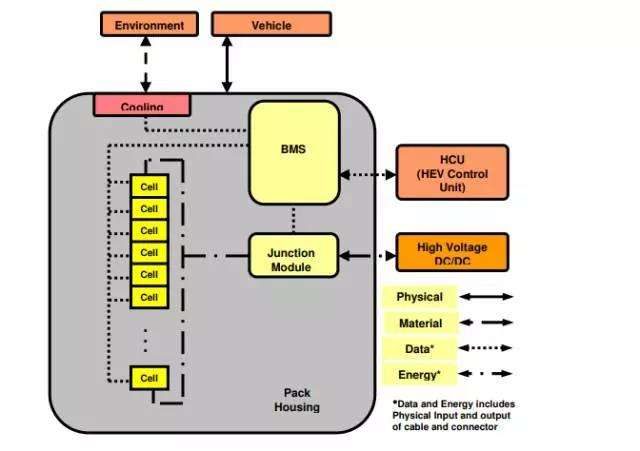

A: We must be clear that the BMS system usually includes a detection module

and a calculation control module.

Detection refers to measuring the voltage, current and temperature of the

battery cell and the voltage of the battery pack, and then transmitting these

signals to the computing module for processing and issuing instructions. So that

the computing control module is the brain of BMS. The control module generally

includes hardware, basic software, runtime environment (RTE) and application

software. The core part-application software.

The function of the software is generally divided into two parts: the

estimation algorithm of the battery state, the fault diagnosis and the

protection.

State estimation includes SOC (State of Charge), SOP (State Of Power), SOH

(State of Health), balance and thermal management. Battery state estimation is

usually to estimate SOC, SOP and SOH. SOC simply means how much power is left in

the battery; SOC is the most important parameter in BMS, because everything else

is based on SOC, so its accuracy and error correction capabilities are extremely

important. If there is no accurate SOC, no amount of protection function can

make the BMS work normally, because the battery will always be in a protected

state, and it will not be able to extend the life of the battery.

In addition, the estimation accuracy of SOC is also very important. The

higher the accuracy, the higher the cruising range for the same capacity

battery. Therefore, high-precision SOC estimation can effectively reduce the

required battery cost. For example, the Fiat 500e BEV of Chrysler can discharge

SOC=5% all the time. It became the electric car with the longest cruising range

at that time.

The accurate estimation of SOP can maximize the utilization efficiency of

the battery. For example, when braking, it can absorb as much energy as possible

without harming the battery. When accelerating, it can provide more power to

obtain greater acceleration without harming the battery. At the same time, it

can also ensure that the car will not lose power due to undervoltage or

overcurrent protection during driving, even when the SOC is very low.

In this way, the so-called primary protection and secondary protection are

incidental products in the face of precise SOP. Not that protection is not

important. Protection is always needed. But it cannot be the core technology of

BMS.

For low temperature, old batteries and very low SOC, accurate SOP

estimation is especially important. For example, for a group of well-balanced

battery packs, when the SOC is relatively high, the SOC difference between each

other may be very small, such as 1-2%. But when the SOC is very low, the voltage

of a certain cell will drop rapidly. The voltage of this battery cell is even

more than 1V lower than the voltage of other batteries. To ensure that the

voltage of each cell is not lower than the minimum voltage given by the battery

supplier, SOP must accurately estimate the maximum output power of the cell

whose voltage drops rapidly at the next moment to limit the use of the battery

and protect the battery.

The core of estimating SOP is to estimate each equivalent impedance of the

battery online in real time.

SOH refers to the state of health of the battery. It includes two parts:

changes in capacity and power. It is generally believed that when the capacity

decreases by 20% or the output power decreases by 25%, the battery life is

reached. However, this does not mean that the battery can no longer be used.

For a pure electric vehicle EV, capacity estimation is more important,

because it is directly related to the cruising range, and the power limit is

only important when the SOC is low. The requirement for SOH also requires both

high precision and error correction capability. And SOH without error correction

capability is meaningless. The accuracy is less than 20%, and it is

meaningless.

The estimation of SOH is also based on the estimation of SOC. So that the

SOC algorithm is the core of the algorithm.

The battery state estimation algorithm is the core of BMS. Everything else

serves this algorithm. So that when someone claims to have broken through or

mastered the core technology of BMS, one should ask him what exactly did BMS do?

Is it an algorithm or an active balance or only the hardware and underlying

software of the BMS? Or just propose a BMS structure?

Some people say that Tesla is great because its BMS can manage 7,104

batteries. Is this its power? Does it really manage 7104 batteries?

Tesla Model S does use 7104 batteries, but only 96 batteries are connected

in series, and the parallel connection can only be counted as one battery, no

matter how many batteries you connect in parallel. Why? Because the battery

packs of other companies only count the number of batteries in series instead of

the number in parallel.

Why is Tesla special? In fact, if you understand Tesla’s algorithm, you

will know that Tesla’s algorithm not only requires a large amount of working

condition data to calibrate, but also cannot guarantee that in any case,

especially Estimated accuracy after battery aging.

Of course, Tesla's algorithm is already at the top of the century. Ordinary

BMS algorithms almost always use current integration plus open circuit voltage

to calculate the initial SOC using open circuit voltage, and then use current

integration to calculate the change in SOC. The problem is that if the voltage

at the starting point is wrong, or the capacity is incorrect, don’t you have to

make a mistake to the end, and it will not be corrected until it is fully

charged again?

Will the voltage at the starting point go wrong? Experience tells us that

it will, although the probability is very low. If you want to be foolproof, you

can't just rely on the accurate voltage of the starting point to ensure that the

starting SOC is correct.

B: What kind of algorithm is a good algorithm?

From a control point of view, a good algorithm should have two criteria:

accuracy and error correction capability. The truth is that the higher the

accuracy, the better is the most obvious. Really doing well in the algorithm is

using online real-time estimation of open circuit voltage to achieve online

real-time error correction.

Why is the real-time online estimation emphasized here? What are its

benefits? All the equivalent parameters of the battery are estimated through

real-time online estimation, so as to accurately estimate the state of the

battery pack. Real-time online estimation greatly simplifies the calibration of

the battery. This makes it a reality to accurately control the state of the

battery pack with poor consistency. Real-time online estimation enables both new

batteries and aging batteries to maintain accuracy and robustness or

errorcorrection capability.

Some people often don't know what other people's algorithms are. When a

certain manufacturer produces certain parts of a BMS for a certain manufacturer,

they think that they have mastered the core technology of BMS. Such a statement

is not correct.

C: What are the characteristics of the best BMS in the world?

It can estimate the battery parameters of the battery pack online in real

time to accurately estimate the SOC, SOP, SOH of the battery pack, and can

correct the error or percentage of the initial SOC exceeding 10% and the error

or percentage of the ampere-hour capacity exceeding 20% in a short time A few

of the current measurement error.

When General Motors Corporation of the United States developed Volanda 6

years ago, it did an experiment to test the error correction ability of the

algorithm: remove one of the three battery packs connected in parallel, and at

this time the internal resistance increases by 1/3, When the capacity is reduced

by 1/3. But BMS does not know. As a result, SOC and SOP were all corrected in

less than 1 minute and SOH was then accurately estimated. This not only shows

the powerful error correction capability of the algorithm, but also shows that

the algorithm can always maintain the same estimation accuracy throughout the

battery life cycle.

For computers, if a blue screen appears, we generally only need to restart

the computer. However, for a car, even if the probability of breaking down is

only one in ten thousand, it is intolerable. Therefore, unlike publishing

articles, automotive electronics needs to ensure that it can work under any

circumstances.

To make a good algorithm requires a lot of energy to solve those situations

where the probability of occurrence is only one in a thousand or one in ten

thousand. Only in this way can it be guaranteed to be foolproof. The precise

mathematical model is the diffusion equation described in the textbook. But it

cannot be used in the car because the computational complexity of the numerical

solution is too large. The CPU computing power of the BMS is not enough. This is

not only an engineering problem, but also a math and physics problem. Solving

such technical problems can resolve almost all known polarization problems that

affect battery state estimation.

D: The state estimation technology of BMS is the core technology of

BMS.

Although 6 years have passed, there is still no supplier in the world that

can achieve such high accuracy and high error correction ability to ensure the

foolproof operation of the battery.

Even Tesla is unable to achieve perfect estimation technology. Because

Tesla's algorithm cannot guarantee the accuracy and error correction ability of

the battery after aging. Otherwise, why would there be so many Tesla cars in

need of emergency rescue?

Only algorithms that can guarantee high accuracy and high error correction

capabilities are the core technology of BMS!

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

replacement for lead-acid batteries, and they are the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.