Panasonic's technical route and plan for power battery

Panasonic released a video introduction of battery technology route and

manufacturing "Evolution of Battery Technology and Manufacturing at

Panasonic".

In this video, Panasonic identified some interesting content:

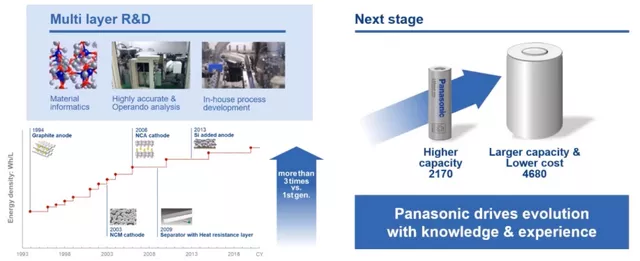

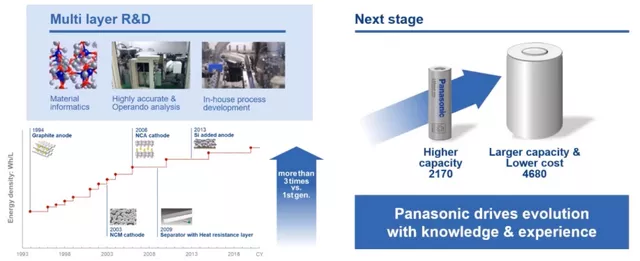

Panasonic confirmed that the next stage of power battery development is to

shift to larger capacity batteries. Tesla's 4680 model (46 mm in diameter and 80

mm in height) is also the direction Panasonic agrees. The development is

currently in progress, and Panasonic will make a large investment in the later

period.

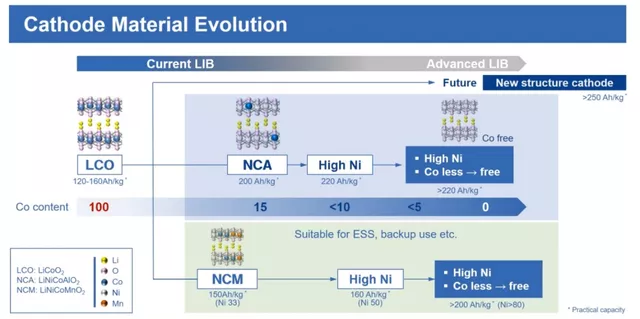

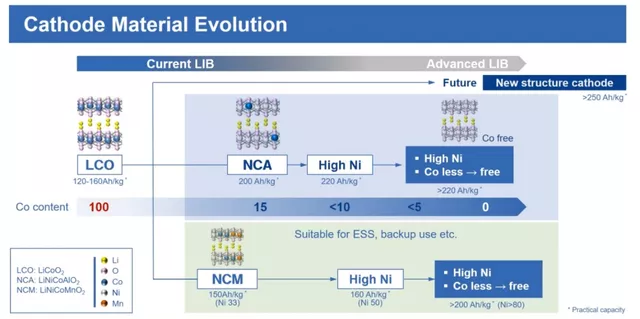

In terms of cathode materials, Panasonic has divided the two routes of NCA

and NCM, the direction is high nickel; the negative electrode is in the two

directions of low cost, high capacity and low cost and high power.

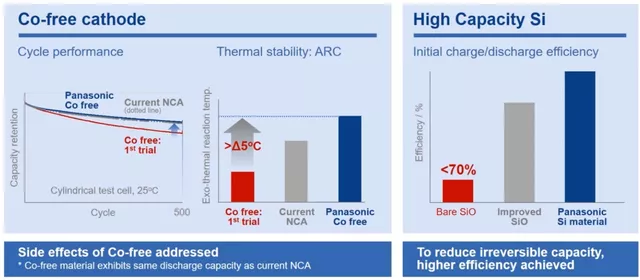

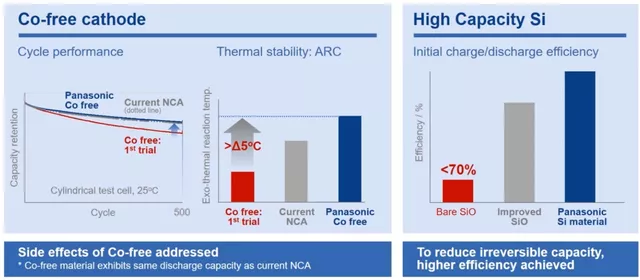

In terms of technical routes, Panasonic continues to use its own

cobalt-free batteries, with performance comparable to the current NCA.

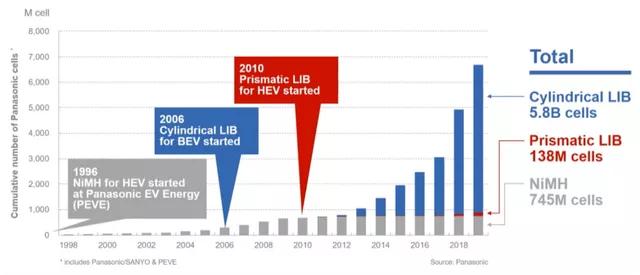

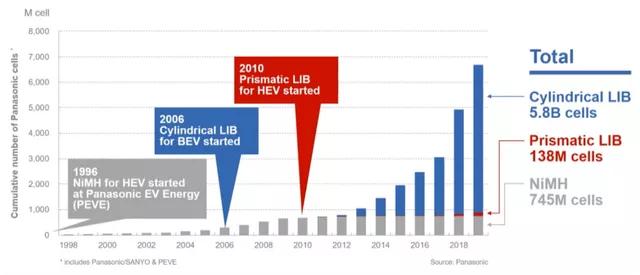

At present, in terms of the number of batteries, Panasonic is still the

king of power batteries. A year can produce 5.8 billion cylindrical batteries

and 138 million square batteries.

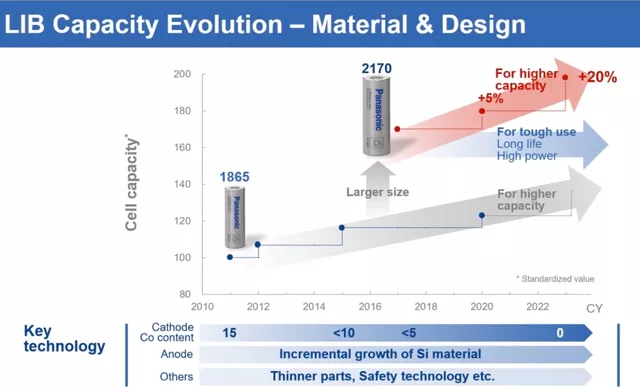

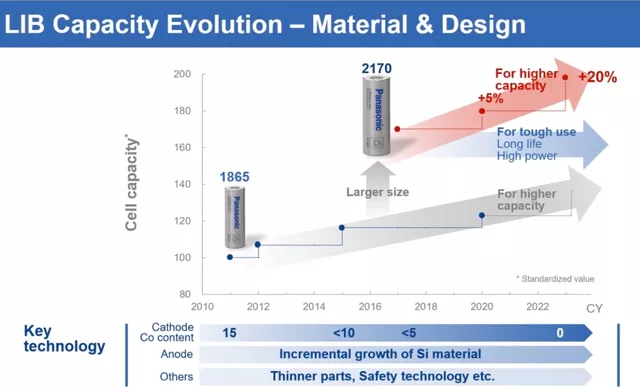

In the MY2021 version, Panasonic upgraded the battery capacity of 21700,

increasing the capacity by 5%, as shown below. In the 2023 plan, there is still

20% room for improvement.

The improvement of battery energy density is not the only goal of

Panasonic's research and development. As demand increases, Panasonic aims to

improve the sustainability of power battery materials (reduce the cobalt content

in the positive electrode) and reduce costs. At present, the cobalt content of

Panasonic's NCA battery is less than 5%, and the company is developing a

cobalt-free version. Remarks: The NCM-based route is suitable for energy storage

and UPS applications, and there is a 10% energy density difference with the NCA

version.

From the current point of view, the proportion of CATL's battery usage in

Tesla is gradually increasing, and there is a difference between the high energy

density route that Panasonic adheres to and Tesla's cost-effective route. If the

real cost of high nickel can be effectively reduced, it can still pose a

challenge to iron lithium.

The next breakthrough direction is to realize the development of low-cost,

high-capacity, low-cost and high-power anode materials, mainly based on graphite

doping. The main products include silicon-carbon (Si/C) anode materials and

silicon-oxygen (SiO/C) anodes. Two kinds of materials.

Panasonic's overall technical route is facing the direction of high nickel

without cobalt and the direction of silicon anode, which is in fact consistent

with the direction of Tesla's high energy density.

Panasonic’s previous strategy of highly bundling Tesla has achieved great

success. However, with Tesla’s expectations of lower costs and increased demand,

Panasonic has developed a strategy to reduce its dependence on Tesla for some

time and strengthen its bundling with Toyota. , But the output has not been

greatly improved.

With the new CEO selling Tesla shares and making a lot of money, Panasonic

plans to start production of 4860 battery production lines in Japan in fiscal

year 2022 (April 1, 2021 to the end of March 2022). Judging from the next market

demand, the demand for 4680 batteries is still very large.

In the short term, lithium iron phosphate has indeed gained a large market

share in the low-end markets in China and the world. However, after the 4680

comprehensive improvement in quality and normal supply starting from 2022, it

will drive the development of high-nickel batteries in 2023-2024. Deployment,

this is good news for consumers, after all, there is one more high-quality

option.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

substitute for lead-acid batteries, and are the first choice for grid-connected

peak shaving, off-grid energy storage, photovoltaic energy storage, UPS, data

center and other industries.