How to evaluate the battery performance and safety of EV?

The battery of an electric car is a complex system. It can be easily

understood in 3 levels:

1. Batteries: positive electrode material, negative electrode material and

electrolyte form the battery core.

2. Battery pack: Hundreds to thousands of batteries are combined to form a

battery pack, commonly known as Pack.

3. System: add sensors (eyes and ears) to measure voltage, current, and

temperature; use BMS (brain) to think and make decisions; add actuators (hands

and feet) to control switches, and it becomes a system.

The safety of the battery system can be understood from the three levels of

battery cells, battery packs, and systems.

A. Safety at the cell level

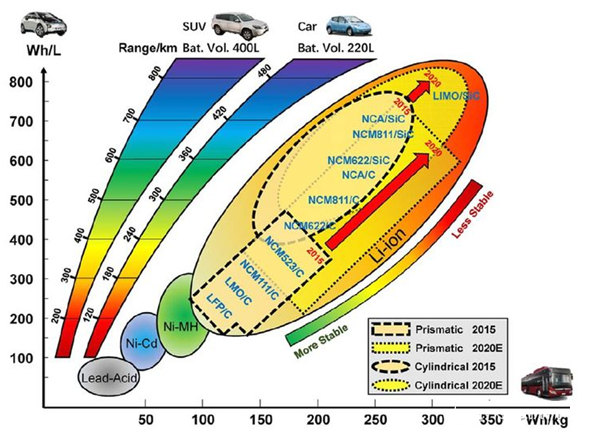

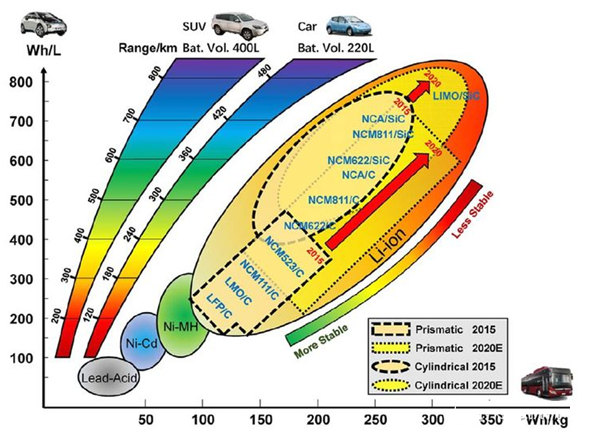

The danger of lithium-ion batteries is mainly reflected in thermal runaway.

We can choose more stable and non-flammable batteries.

Lithium iron phosphate (LFP) is more stable than ternary lithium.

Among ternary lithium, lithium nickel cobalt manganate (NCM) is more stable

than lithium nickel cobalt aluminate (NCA).

In NCM, NCM622 is more stable than NCM811.

The higher the energy density, the more unstable the battery. This

conflicts with the idea that the smallest volume seeks the largest energy.

In the absence of a breakthrough in battery principle, what we can do in

the short term is to improve the stability and safety of the battery as much as

possible. This is a problem involving materials science and

electrochemistry.

B. Security at the PACK level

If the cell level is concerned with the characteristics of the battery

itself, then the PACK level focuses on the relationship between the battery and

the environment, including heating, squeezing, acupuncture, water immersion,

vibration, and so on.

Safety at the PACK level is mainly guaranteed by international standards:

ISO 12405-2014, IEC 62133-2015, UL 2580-2010, SAE J2464, SAE J1929-2011, JIS-C

8715-2-2012, etc.

In order to meet the stringent test standards, some safety designs need to

be made in the mechanical and electrical aspects of the battery pack:

-Mechanical safety design: protective structure, waterproof design,

foolproof design, fire and flame retardant design, etc.

-Electrical safety design: contact protection, external short-circuit

protection, over-current protection design, high-voltage interlock detection,

insulation detection, etc.

Generally speaking, the standards at the PACK level are comprehensive and

strict.

C. Security at the system level

The battery cells make up the battery pack. Although it can pass various

rigorous tests, it is still a dead thing. BMS gives it eyes and ears (sensors),

brain (decision-making), hands and feet (actuators). BMS functions are divided

into two categories:

Primary function: For example, outputting and receiving energy (thereby

driving the vehicle) are the basic functions of the battery.

Monitoring function: For example, safety measures under faults such as

overcurrent, overvoltage, and communication interruption are designed, which is

actually a safety monitoring design for the battery system.

Whether these safety monitoring functions are done adequately and

comprehensively determines the ability of the battery system to cope with

failures and stifle thermal runaway in the cradle. Because thermal runaway often

occurs in the state of full charge and overcharge, the particularly critical

link is charging.

D. Is there a fourth level? —— ISO26262 and functional safety

Please think about it, if the three levels of battery, PACK, and system are

in place, what else might cause thermal runaway?

Force majeure: severe traffic accidents lead to severe battery deformation;

electric cars drive into a fire; drive into water to soak for one month; go to

unqualified auto repair shops to disassemble at will...

Aging: It is impossible to accurately predict the true state of the battery

in three, five or even ten years.

In fact, most manufacturers have certified that they design electric

vehicles in accordance with standards, but it is still very common for electric

vehicles to catch fire and lose control. Then why do we follow the standards,

and there will still be accidents?

The reason is simple: any hardware may fail; any software is written by

humans, and humans may make mistakes. Specifically, it may be:

Unreasonable system architecture: Reliance on external systems, and the

development of the designed architecture is too difficult

Reliability is not up to standard: the reliability of the hardware does not

meet the strict level of the corresponding risk

Unreasonable development process: software development process, developer

qualification, independence of testing and verification

This is the so-called fourth level: function safety. Note that functional

safety is not "guaranteeing that the function operates safely", it is

"guaranteeing safety in the event of a function failure".

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

replacement for lead-acid batteries, and they are the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.