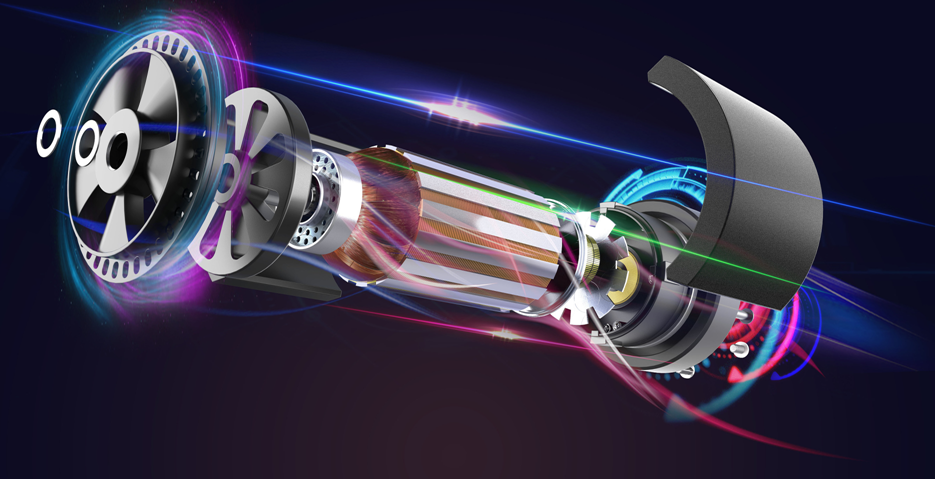

The basic content needed to select the correct motor model are: the type of

load being driven, the rated power, the rated voltage, and the rated speed.

1. Rated power

The rated power of the motor refers to the output power, that is, the shaft

power, also called the capacity. It is the most important index to quantify the

motor's drag load capacity, and it is also the parameter requirement that must

be considered when the motor is selected.

The power of the motor should be determined in the most economical and

reasonable manner on the premise that the motor can meet the requirements of the

production mechanical load. If the power is selected too large, the equipment

investment will increase, resulting in waste, and the motor often runs under

load, and the efficiency and power factor of the AC motor are low; on the

contrary, if the power is selected too small, the motor will run with overload,

causing the motor to run prematurely damage.

2. The type of load driven

Motors can be simply divided into DC motors and AC motors, and AC is

further divided into synchronous motors and asynchronous motors.

The principle of selecting a motor is that on the premise that the

performance of the motor meets the requirements of the production machinery, the

motor with simple structure, low price, reliable work and convenient maintenance

is preferred. In this respect, AC motors are superior to DC motors, AC

asynchronous motors are superior to AC synchronous motors, and squirrel cage

asynchronous motors are superior to winding asynchronous motors.

For production machinery with stable load and no special requirements for

starting and braking, ordinary squirrel-cage asynchronous motors should be

preferred, which are widely used in machinery, water pumps, fans, etc.

Starting and braking are more frequent, and production machinery that

requires larger starting and braking torques, such as bridge cranes, mine

hoists, air compressors, and irreversible rolling mills, should use wound

asynchronous motors.

Where there is no requirement for speed regulation, a constant speed or

improvement of power factor is required, synchronous motors should be used, such

as medium and large-capacity water pumps, air compressors, hoists, mills,

etc.

The speed regulation range is required to be above 1:3, and the production

machinery that needs continuous, stable and smooth speed regulation should adopt

a separately excited DC motor or a squirrel cage asynchronous motor or

synchronous motor with frequency conversion speed regulation, such as large

precision machine tools, planers, Rolling mills, hoists, etc.

The production machinery that requires large starting torque and soft

mechanical characteristics uses series-excited or compound-excited DC motors,

such as trams, electric locomotives, and heavy-duty cranes.

3. Rated voltage

The rated voltage of the motor refers to the line voltage in the rated

working mode.

The selection of AC motor voltage level mainly depends on the power supply

voltage level of the place where it is used. Generally, the low voltage network

is 380V, so the rated voltage is 380V (Y or △ connection), 220/380V (△/Y

connection), 380/660V (△/Y connection).

The rated voltages of DC motors are generally 110V, 220V and 440V. Among

them, 220V is a common voltage level, and high-power motors can be increased to

600~1000V.

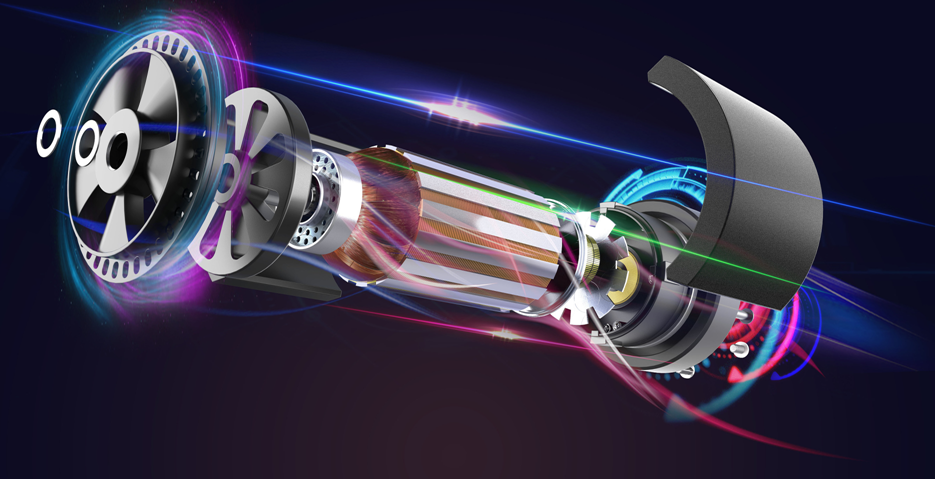

4. Rated speed

The rated speed of the motor refers to the speed in the rated working

mode.

The motor and the working machine dragged by it have their own rated speed.

It should be noted that the speed should not be too low, because the lower the

rated speed of the motor, the more the number of stages, the larger the volume

and the higher the price. At the same time, the speed should not be too high,

because this will make the transmission mechanism too complicated and difficult

to maintain.

The rotor of the motor will vibrate during operation, and the amplitude

reaches the maximum at a certain speed, which is commonly referred to as

resonance. The speed with the largest amplitude of the rotor is called the

critical speed of the rotor.

When the rotor is running at a critical speed, severe vibration will occur,

and the curvature of the shaft will increase significantly. Long-term operation

will also cause severe bending and deformation of the shaft, or even breakage.

This effect should be considered when determining the speed parameters to avoid

long-term use of the motor in the critical speed range.

Generally speaking, the motor can be roughly determined by providing the

type of load driven, the rated power of the motor, the rated voltage, and the

rated speed. But if the load requirements are to be optimally met, these basic

parameters are far from enough. The parameters that need to be provided include:

frequency, operating system, overload requirements, insulation level, protection

level, moment of inertia, load resistance torque curve, installation method,

ambient temperature, altitude, outdoor requirements, etc., according to specific

conditions.

Lithium-ion battery (LIB) has become the main energy storage solution in

modern social life. Among them, lithium iron phosphate batteries are a perfect

replacement for lead-acid batteries, and they are the first choice for

grid-connected peak shaving, off-grid energy storage, photovoltaic energy

storage, UPS, data center and other industries.

The motor system is matched with a high-rate performance lithium battery

system, which is a very promising way to use it.